google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Coating of perovskite cell films——deposition technology——Shanghai Yangmi ultrasonic spraying

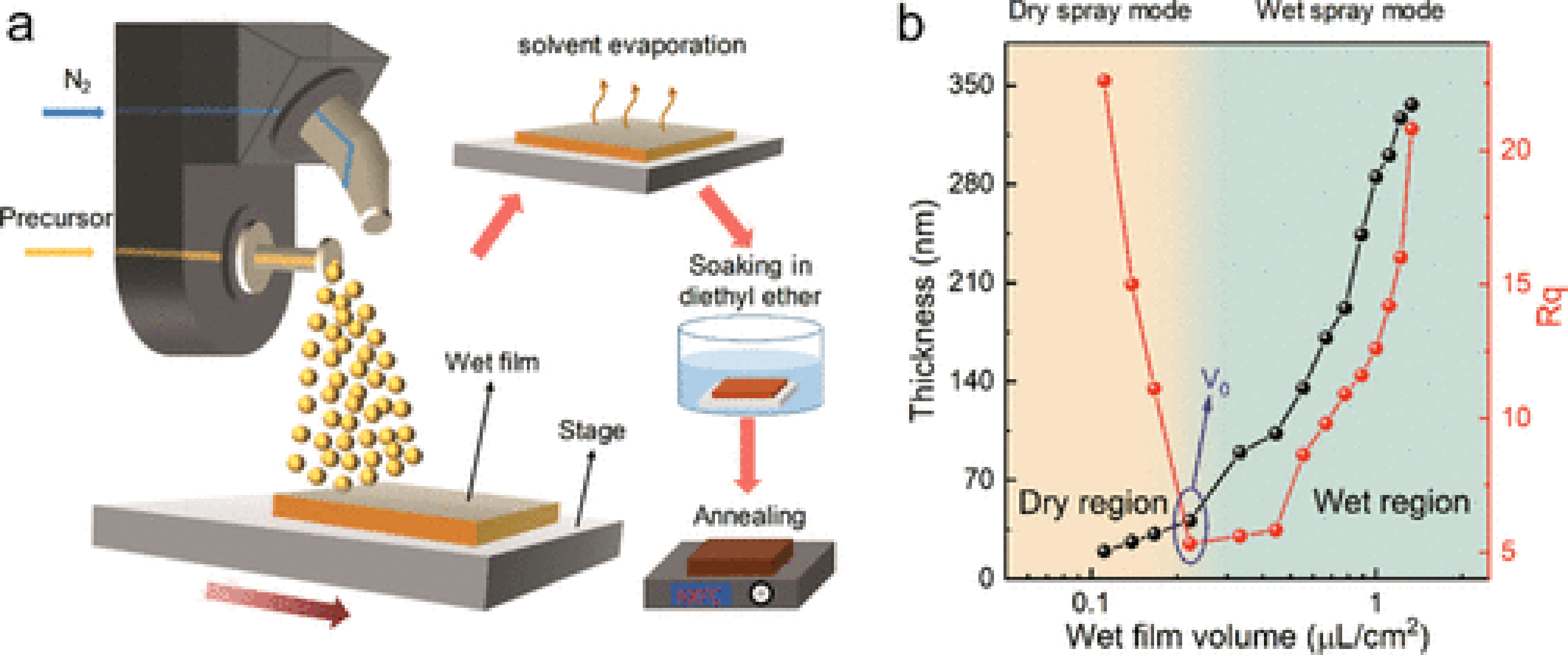

Spraying is a simple and low-cost deposition technique for large areas of PPM, in which droplets of a precursor solution are sprayed through a sprinkler head and polymerized into a wet film on the substrate. And the solvent evaporates in the wet film leaving a solid film. Since the nozzle is not in contact with the substrate, it can be sprayed on a variety of surfaces.

Spraying is usually formulated with a lower concentration of ink to produce the required thickness of perovskite film. If the solvent evaporates too quickly, the droplets of the solution do not have enough time to disperse and combine into a uniform film. Conversely, if the drying process continues for a long time, the wet film will shrink into a film with poor coverage. Therefore, the control of spraying perovskite film is a big challenge, and the PCE of spraying device is relatively low. The quality and thickness of the film can be improved by optimizing spraying speed, substrate temperature, nozzle distance from substrate, wet film annealing temperature and time, as well as ink concentration, viscosity and solvent flux.

Shanghai Yangmi transmission ultrasonic spraying system, a mass-production automatic ultrasonic spraying equipment, can be equipped with wide spray ultrasonic nozzle, and can be equipped with multiple nozzle parallel work, equipped with automatic transmission machine can automatically transmit samples, suitable for mass production and large area film spraying, reduce costs, improve the quality of the film layer.