google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Uniform anti-corrosion chemical film coating and protective anti-scratch polymer -- float glass -- YMUS ultrasonic spray

Apply to float glass during the antifouling coating process to prevent stage I and II corrosion. A uniform coating of acid mixture is deposited on the glass to prevent stains from forming during transportation and storage. Float glass coating systems that use ultrasonic spraying are an effective alternative to powder or pressure spraying processes and have significant advantages over other spraying methods, most importantly do not clog and rarely overspray the material. A very thin, uniform, durable layer is applied to the glass for excellent protection with minimal exhaust and energy requirements during deposition, low drying time, and the coating is easily washed off.

Note:Float glass

Wide area coating of protective polymer on Low-E glass

YMUS Ultrasonic sprayed glass coating system is commonly used for wide area coating of low-E glass with thin protective polymer solutions. Ultrasonic spraying will not clog the nozzle, reduce downtime cleaning time, precise control of solution coating thickness, solution conversion rate > 95%. This environmentally friendly thin film coating reduces material consumption, deposits thinner, more uniform layers, is drip-free, and greatly reduces maintenance.

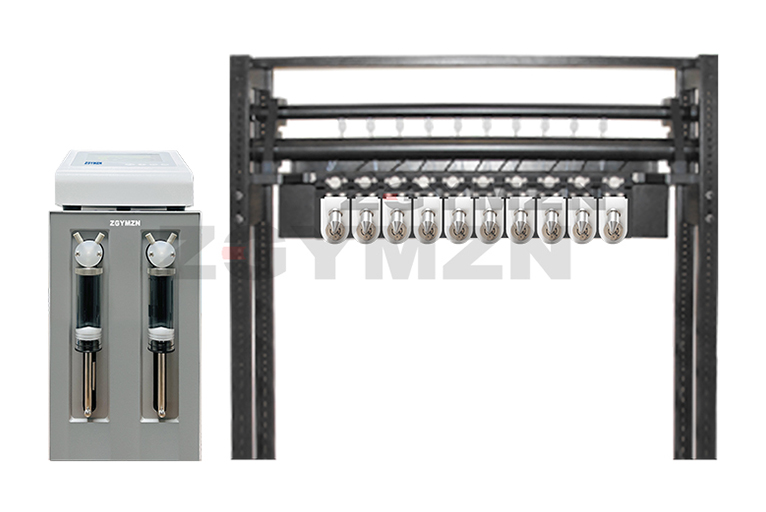

YMUS-ZX1000 Ultrasonic spraying system

Equipment characteristics

◆ Can be integrated to all fields of industrial assembly line installation;

◆ Can be matched with a large wide nozzle, uniform cover a large area of substrate;

◆ Can be equipped with multiple nozzle array, greatly improve the production speed;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times the traditional two fluid spraying;

◆ Full color touch screen control and friendly man-machine interaction interface;

◆ All kinds of high precision constant current liquid supply system, matching different production capacity and different process requirements;

◆ Non-blocking sprinkler technology, low maintenance cost;

◆ Ultrasonic dispersion liquid storage barrel, ultrasonic dispersion syringe, avoid solid precipitation in the spraying process; (extensible)

◆ Liquid level alarm system;