google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

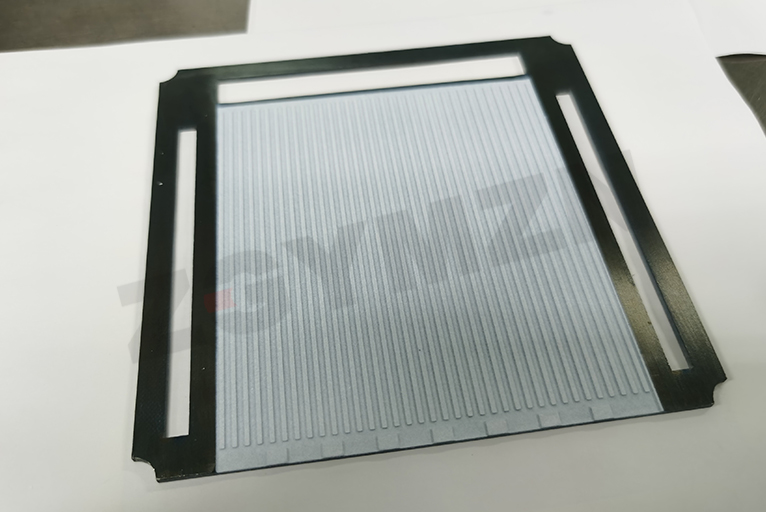

SOFC solid oxide coating preparation - future energy - YMUS ultrasonic spraying

Solid Oxide Fuel Cell (SOFC) is a third-generation fuel cell. It is an all-solid-state device that directly converts chemical energy stored in fuel and oxidant into electrical energy efficiently and environmentally friendly at medium and high temperatures. The chemical power generation device has the highest theoretical energy density among several types of fuel cells. It is generally considered to be a fuel cell that will be as widely used as the proton exchange membrane fuel cell (PEMFC) in the future.

With the increasing demand for clean energy and the emphasis on energy transformation, SOFC, as an efficient and environmentally friendly energy conversion technology, is considered an important part of the future energy system. Therefore, ultrasonic spray technology has an important position and potential in the preparation and research and development of SOFC. It is expected that in the future, with the continuous advancement and maturity of technology, the application of ultrasonic spray technology in the field of SOFC will be more extensive, and will bring new opportunities and challenges to the development of the industry.

Ultrasonic spray technology has broad prospects in the field of SOFC. It can be used to prepare different types of coatings, such as cathode, anode coatings, electrolyte coatings, etc., to improve the performance, stability and life of SOFC. In addition, this technology can also be applied to other fields, such as catalyst preparation, ceramic coatings, etc.

1. Uniformity: Ultrasonic spraying technology can produce a uniformly distributed coating, making the coating more dense and consistent, which is beneficial to improving the performance and stability of SOFC.

2. Precision: Ultrasonic spraying technology can achieve precisely controlled coating thickness, which is crucial to the performance and stability of SOFC.

3. Improve efficiency: Ultrasonic spray technology can achieve high-speed spraying, improve production efficiency and reduce preparation costs.

4. Applicability: Ultrasonic spraying technology is suitable for SOFC substrates and components of various complex shapes and sizes, and has high adaptability.