google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

As people pay more and more attention to environmental protection and sustainable development, the demand for clean energy is also growing. Fuel cells, as an efficient and clean energy conversion technology, meet the market demand for clean energy and have huge market potential.

Fuel cells have a wide range of applications, such as automobiles, ships, and aviation in transportation; distributed power generation, consumer electronics, etc. In the field of new energy, fuel cells mainly include:

Proton exchange membrane fuel cell (PEMFC)

Application areas: widely used in transportation, such as automobiles, buses and heavy trucks; also used in portable electronic devices and fixed power stations.

Features: fast start-up speed, high energy conversion efficiency, high power density, low operating temperature, environmentally friendly, but requires the use of precious metal catalysts, high cost, and sensitive to impurities such as carbon monoxide.

Phosphoric acid fuel cell (PAFC)

Application areas: mainly used for fixed power generation, such as distributed power stations for hospitals, schools, etc.; also used for large vehicles such as urban buses.

Features: mature technology, can tolerate certain fuel impurities, can use waste heat to achieve cogeneration, but the power generation efficiency is not high when viewed alone, the volume and weight are large, and the cost is high.

Solid oxide fuel cell (SOFC)

Application areas: can be used in large-scale centralized power supply, medium-sized distributed power supply and small household cogeneration and other civil fields as fixed power stations; can also be used as mobile power sources such as ship power supply, transportation vehicle power supply, etc.4.

Features: Wide fuel adaptability, can use a variety of hydrocarbon fuels, high energy conversion efficiency, all-solid structure, no leakage, corrosion problems, but high operating temperature, slow start, high material requirements.

Direct methanol fuel cell (DMFC)

Application areas: Suitable for portable electronic devices such as mobile phones and laptops; can also be used in some small mobile power supplies and distributed power generation scenarios.

Features: High fuel energy density, convenient storage and transportation, simple battery structure, but low energy conversion efficiency, catalyst is easily poisoned.

At present, the mainstream fuel cell in the field of new energy is the proton exchange membrane fuel cell (PEMFC). Its advantages mainly include:

● High power density: It can output higher power in a smaller volume and weight, which is suitable for transportation and other fields with high space and weight requirements.

● Fast start: The operating temperature is low, generally between room temperature and 80℃, and the start-up speed is fast, and it can reach full load working state in a short time.

● Environmentally friendly: The reaction product is mainly water, which is pollution-free to the environment and meets environmental protection requirements.

● High energy conversion efficiency: The electrochemical efficiency is generally 40%-60%, and energy can be effectively utilized in some application scenarios2.

● Good dynamic response: It can quickly adapt to changes in load and can operate stably under different working conditions.

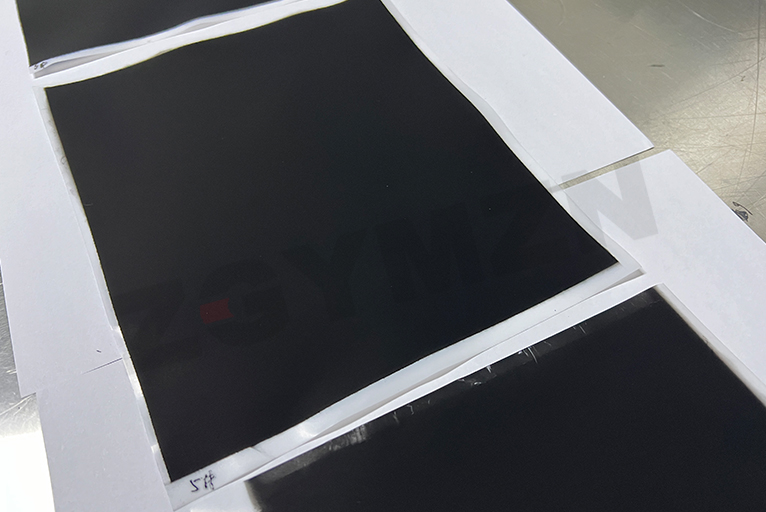

Shanghai Yangmi ultrasonic spraying equipment is used for the preparation of proton exchange membrane coatings. The ultrasonic atomizing nozzle evenly sprays the solution on the surface of substrate materials such as electrodes or proton exchange membranes to form a uniform, thin and dense coating. It is possible to prepare coatings with a thickness of several microns or even thinner, meeting the ultra-thin and high-performance requirements of PEMFC for electrode and membrane coatings, which is beneficial to improving the power density and reaction efficiency of the battery. During the spraying process, the atomized droplets have a lower speed and energy, and have less impact on substrate materials such as electrodes and proton exchange membranes, which can effectively avoid damage to the substrate structure and performance. It can adapt to a variety of coating materials with different properties, including various catalyst inks, polymer electrolytes, etc., and can also match PEMFC components of different shapes and sizes.

With the continuous advancement of technology, reduction of costs and policy support, fuel cells are expected to play an increasingly important role in the future energy field and make important contributions to achieving global sustainable development goals.