google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Plasma activation -- Improving product surface tension -- Shanghai Yangmi plasma treatment

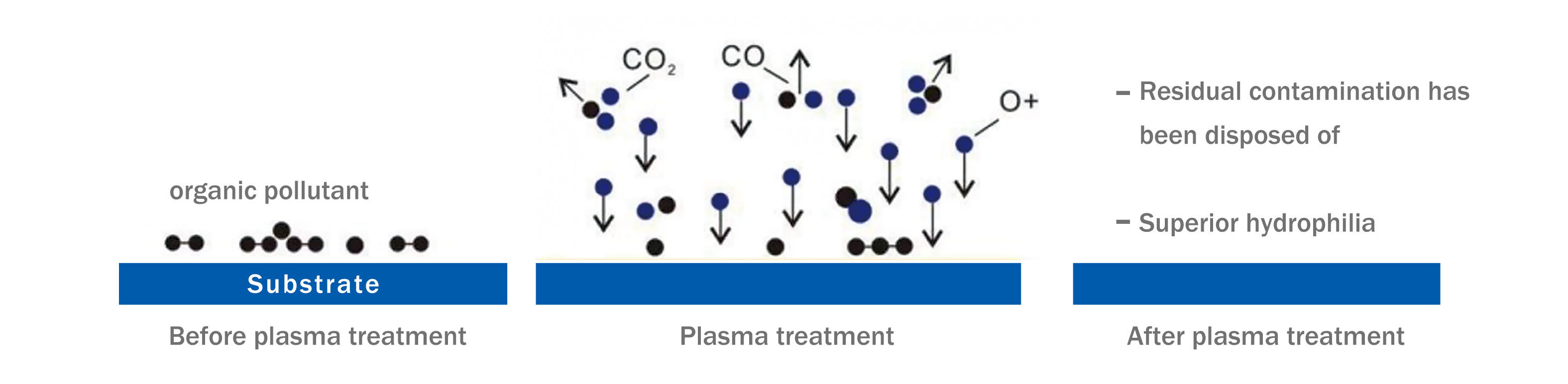

Plasma processing mechanism:

Process gas is ionized into plasma by applying an electric field to it. Plasma treatment is to make use of the properties of these active components to oxidation, reduction, cracking, cross-linking and polymerization and other physical and chemical reactions to change the surface properties of the sample, so as to optimize the surface properties of materials, to achieve cleaning, modification, etching and other purposes.

Before and after plasma treatment

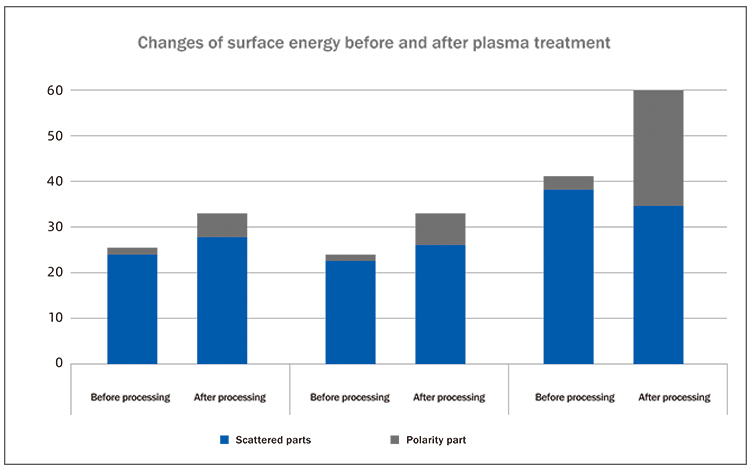

Plasma pretreatment:

Plasma pretreatment measures the surface tension of materials, through the measurement of ink and contact Angle and other parameters to analyze the use of plasma equipment to plastic surface pretreatment after the impact of the surface energy of the material.

Surface energy changes before and after plasma treatment

Plasma processing features:

● Can choose different processing wide plasma nozzle, to meet the needs of product processing;

● Working gas: compressed air, low cost;

● No pollutant emissions, no environmental concerns;

● Good processing effect, stable operation, simple operation;

● No damage to the surface of the material;

● Low maintenance cost;

Atmospheric plasma processing system