google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Semiconductor silicon wafer megasound cleaning equipment and device——semiconductor wafers——Shanghai Yangmi Megasound cleaning

The SAPS technology provides uniform sound energy at each point throughout the wafer by alternating phases of the megabit wave in the gap between the megabit cleaning device and the wafer. The Megabyte wave energy can be transmitted to the bottom of the TSV, and compared with the traditional single chip jet cleaning method, the SAPS cleaned the chip shows obvious improvement in electrical performance. Compared to traditional wet cleaning methods, SAPS megabit wave technology shows high residue removal efficiency and low material loss for high aspect ratio perforations.

Commonly used semiconductor silicon wafer cleaning equipment and devices:

1. Mega sound cleaning tank

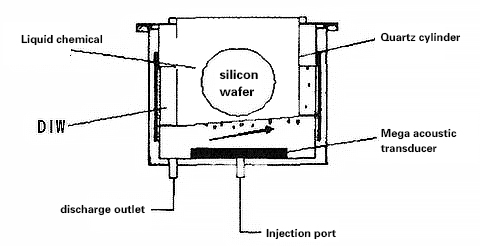

RcA or improved RcA cleaning combined with mega acoustic energy is a very widely used cleaning method at present. With the addition of megasound energy, the use temperature and process time of the solution can be greatly reduced, and the cleaning effect is more effective. The commonly used frequency of megasound cleaning is 800kHz-1MHz, and the megasound power is 100-600W. Mega acoustic transducer has plate type, arc plate type and other forms. Mega acoustic transducer can be directly installed at the bottom of the tank; Quartz cleaning tank can be used in the way of water bath, mega acoustic transducer installed at the bottom of the outer tank, so as to avoid the corrosion of the cleaning liquid on the mega acoustic transducer.

Mega sound cleaning tank High frequency megatonic cleaning machine

A large number of bubbles will be generated at the bottom of the quartz groove during the operation of the mega acoustic transducer. These bubbles will absorb a lot of megasound energy, greatly reducing the effectiveness of megasound cleaning. Therefore, the bottom of the quartz cylinder in the inner groove generally has 10-15 degrees of inclination. When there are bubbles, the bubbles move upward along the bottom of the inclined quartz groove due to the action of buoyancy, and surface from the quartz groove wall, reducing the loss of the bubbles to the megaacoustic energy.

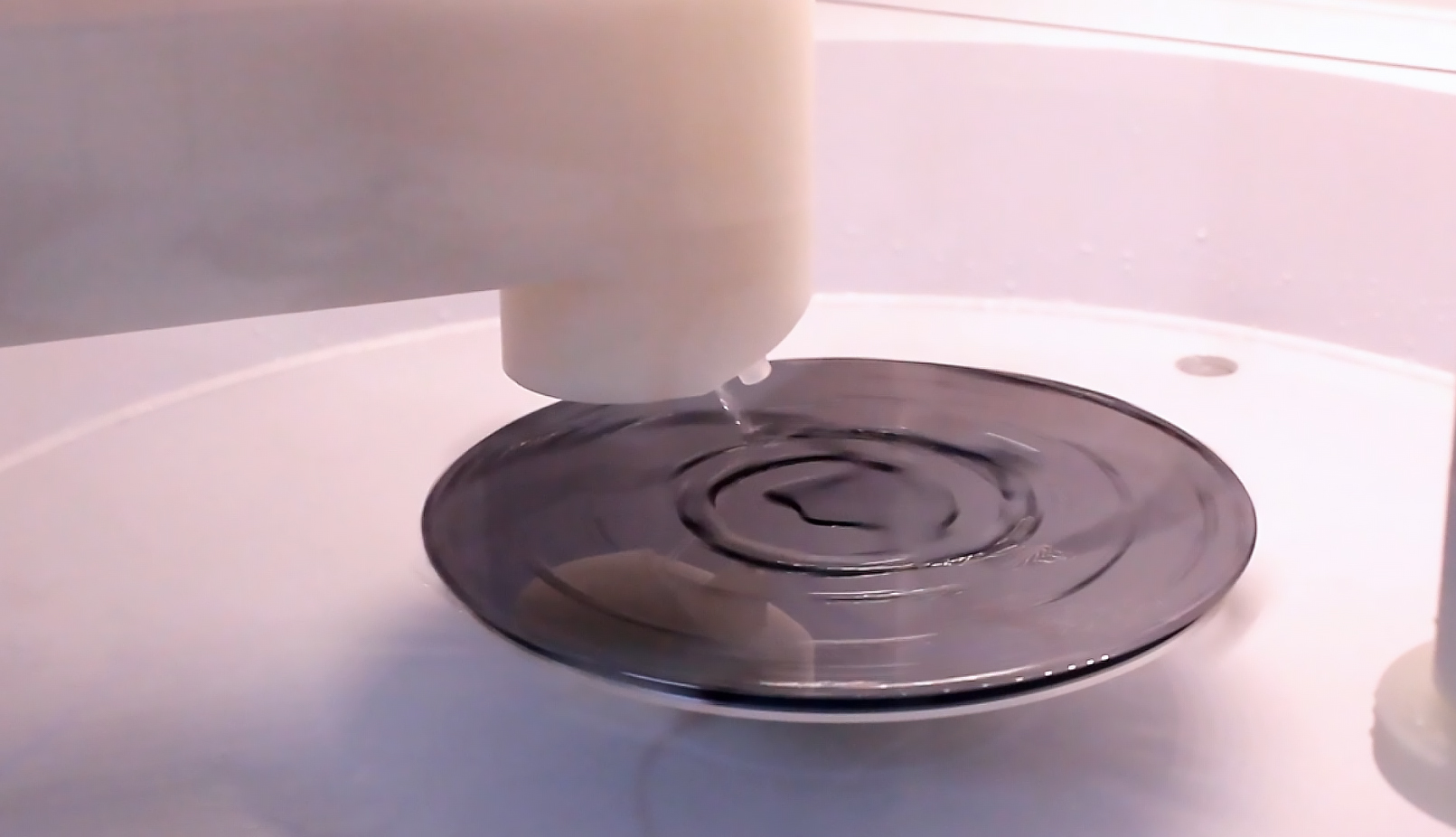

2. rotary spray cleaning

Rotary spray cleaning is a variant of immersion cleaning. The system generally includes automatic liquid dispensing system, cleaning chamber, waste liquid recovery system. Spray cleaning in a sealed working chamber to complete the chemical cleaning, deionized water washing, rotary dry and other processes, reducing the impact of human factors in each step of the cleaning process. In spray cleaning, due to the effect of rotation and spray, the solution on the surface of the silicon wafer is more uniform. At the same time, the solution that comes into contact with the surface of the silicon wafer is always fresh. In this way, the cleaning corrosion effect of the silicon wafer can be accurately controlled through the setting of process time, and a good consistency can be achieved. The sealed working chamber can isolate the volatilization of chemical liquid, reduce the loss of solution and the harm of solution vapor to human body and the environment. Each system is stored separately with different chemicals, which are mixed before they reach the nozzle at the time of use to keep them fresh and to maximize their potential so that they will react fastest during cleaning.

Mega sound spray cleaning head Rotary spray cleaning

Shanghai Yangmi mega acoustic cleaning system automatic trough cleaning equipment, high frequency mega sound cleaning machine, mega sound cleaning nozzle, etc. We will provide refined cleaning technology for effective application in your industry area.