google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spraying superhydrophobic coating -- nano coating -- YMUS ultrasonic spraying

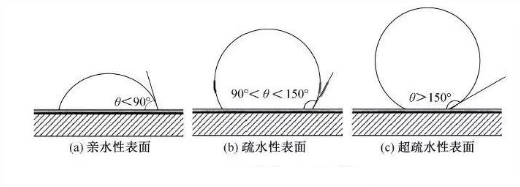

Hydrophobicity refers to the physical property of a molecule (hydrophobic) that repels water. Hydrophobic molecules tend to be non-polar and thus more soluble in neutral and non-polar solutions (such as organic solvents). Hydrophobic molecules usually cluster together in water, which forms a droplet shape with a large contact Angle on the surface of the hydrophobic solution. Water molecules interact differently with the surfaces of different solid materials. At the intersection of water (liquid phase), matter (solid phase), and air (gas phase), the Angle θ formed along the tangent line of the droplet surface and the contact surface between water and matter is called the contact Angle. The contact Angle between hydrophilic material and water is less than 90 degrees. The contact Angle of hydrophobic is greater than 90 degrees and less than 150 degrees, and the contact Angle of superhydrophobic is greater than 150 degrees.

We all know that after rain, water droplets will not stick to the surface of the lotus leaf, but like a pearl like rolling back and forth on the leaf surface, which is the most common phenomenon of superhydrophobic nature. Due to its excellent superhydrophobic properties, superhydrophobic materials have a wide range of application prospects in national defense, glass, industrial and agricultural production and daily life. For example, superhydrophobic coatings can be widely used in scenes requiring water repellent and antipollution.

YMUS ultrasonic atomizing spraying equipment to prepare superhydrophobic coating, the smaller the diameter of the solution, the more uniform atomizing dispersion. The hydrophobic coating prepared by this method not only has good waterproof, oil, pollution, corrosion and other effects. Characteristics of ultrasonic spraying equipment:

◆ Ultrasonic spraying equipment, using ultrasonic nozzle technology, can provide uniform and efficient film spraying;

◆ High precision of coating thickness control: tens of nanometers to tens of microns of coating can be prepared, accurate control of coating thickness;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times the traditional two fluid spraying;

◆XYZ three-axis servo motion system;

◆ Full color touch screen control and friendly man-machine interaction interface;

◆ High precision laboratory injection pump;

◆ Wide range of liquid flow: 0.001ml/ min-50ml /min; (Depending on the type of solvent and sprinkler)

◆ Imported high-precision pressure-reducing valve and liquid valve, to achieve high-speed and stable gas-liquid coordination;

◆ Laser alignment: to assist users to easily and quickly locate the nozzle position;

◆ Built-in exhaust gas system, does not block the nozzle technology, reduce maintenance costs;

◆ Microporous vacuum heating, suitable for battery diaphragm and other flexible substrates; (extensible)