google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic to achieve large area, high performance ultra-thin dielectric film - film spraying - YMUS ultrasonic spraying

As an indispensable part of modern advanced electronic and power systems, dielectric film capacitors have superior power density, fast charge-discharge performance, ideal cycle characteristics, high voltage operation, self-healing and high reliability. In particular, high temperature capacitor storage film capacitors have a wide range of applications in extreme conditions, including inverters in electric vehicles, integrated power electronics capacitors and aerospace power supplies. However, it is still challenging to prepare high-quality expandable ultra-thin dielectric films for high temperature dielectric energy storage films. For example, the thickness of high-temperature dielectric films is usually limited to 10μm, while the most advanced commercially available bi-oriented polypropylene (BOPP) -based capacitor films can be less than 2.5μm thick. In addition, hot carrier excitation, injection and transport can significantly limit the energy density of high temperature media.

Note:Ultrathin dielectric film prepared by ultrasonic spraying

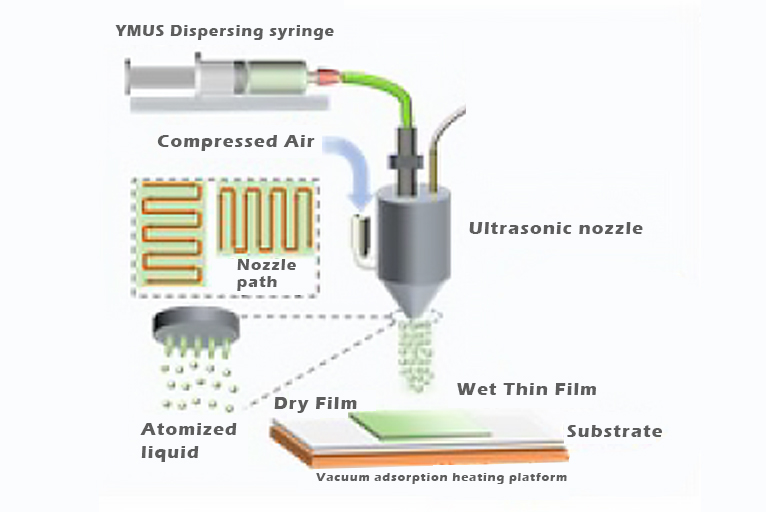

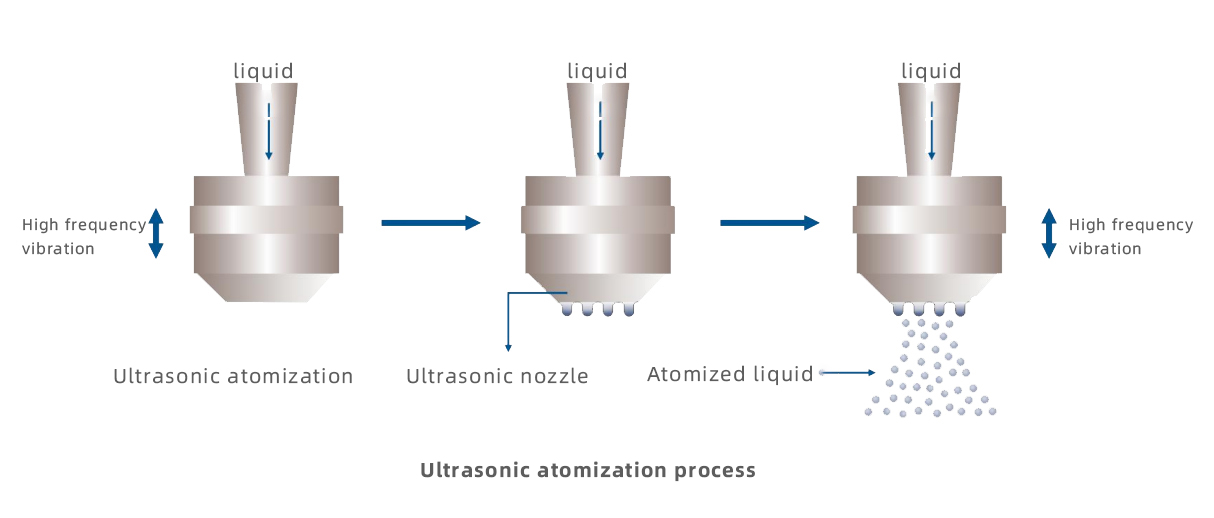

YMUS ultrasonic spraying technology to prepare high quality ultra-thin dielectric films. In the spraying process, the sol is transferred to the atomizing nozzle through the YMUS ultrasonic dispersing syringe and atomized into micron-scale tiny droplets through the high-frequency vibration in the nozzle. Then, under compressed air, tiny droplets are deposited evenly on the substrate. The droplets remain below the nozzle and coalesce to form an ultra-thin, wet coating film. The wet film is driven by the vacuum adsorption heating platform, and the solvent evaporates to form a dry solid film. In order to prepare the final ultra-thin dielectric film, the dry film should be further heat treated to remove the residual solvent. In ultrasonic spraying technology, a uniform wetting layer is a prerequisite for the formation of continuous high-quality organic films.

Note:Ultrasonic nozzle atomization process

YMUS ultrasonic spraying equipment has the characteristics of uniform, controllable thickness, flat surface and no defect, which enables us to successfully prepare high-quality ultra-thin dielectric films by ultrasonic spraying.

YMUS-ZS400 ultrasonic spraying equipment