google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Optical thin film coating technology - AR, QC - YMUS ultrasonic spraying

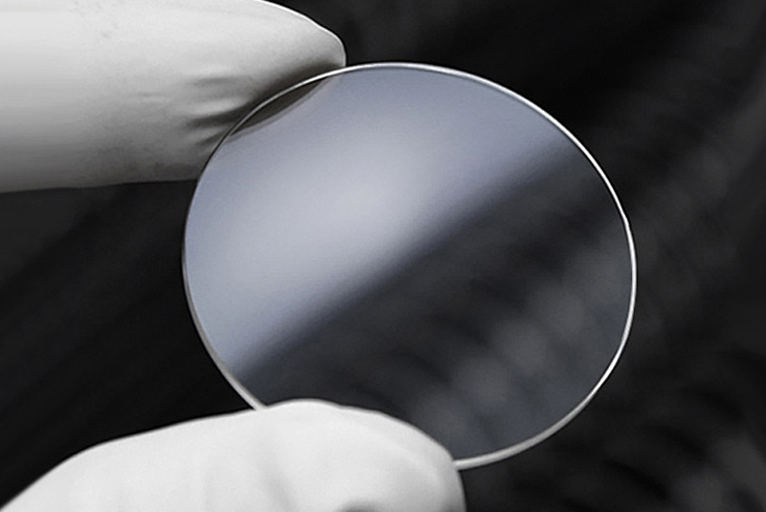

The preparation of ultrasonic spray self-cleaning solutions AR (Anti-Reflective, anti-reflective) and QC (Easy-to-Clean, easy to clean) on glass surfaces is a common application.

Industry applications:

● Optical field: Ultrasonic spray self-cleaning solutions AR and QC are widely used in the manufacturing of optical devices. For example, glasses, camera lenses, optical instruments, etc. AR coating can reduce light reflection and improve light transmittance and image clarity; QC coating can reduce the adhesion of dirt and fingerprints and facilitate cleaning.

● Architectural field: AR coating can reduce reflection on the glass surface, improve indoor lighting effect and visual comfort; QC coating can reduce the adhesion of dirt and dust, reducing cleaning costs.

● Automotive field: AR coating can reduce the reflection of car windows and improve the driver's vision and safety; QC coating can reduce the adhesion of water droplets and dirt, improving the wiper effect and driving comfort.

Analysis of ultrasonic spray technology: Ultrasonic spray technology has the following analytical advantages in the preparation of self-cleaning solutions AR and QC:

● Uniformity: Ultrasonic spraying technology can achieve uniform spraying of the solution, avoid uneven thickness, and provide better coating quality and performance.

● Controllability: Ultrasonic spray technology can precisely control the thickness and composition of the coating to meet specific application requirements.

● High efficiency: Ultrasonic spraying technology can quickly coat a large area of glass surface, improving production efficiency and process controllability.

● Cost saving: Ultrasonic spraying technology can reduce the waste of solution, improve material utilization and reduce preparation costs.

The preparation of YMUS ultrasonic spray self-cleaning solutions AR and QC requires the selection of appropriate solutions and process parameters, and relevant testing and verification to ensure the quality and performance of the coating.