google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

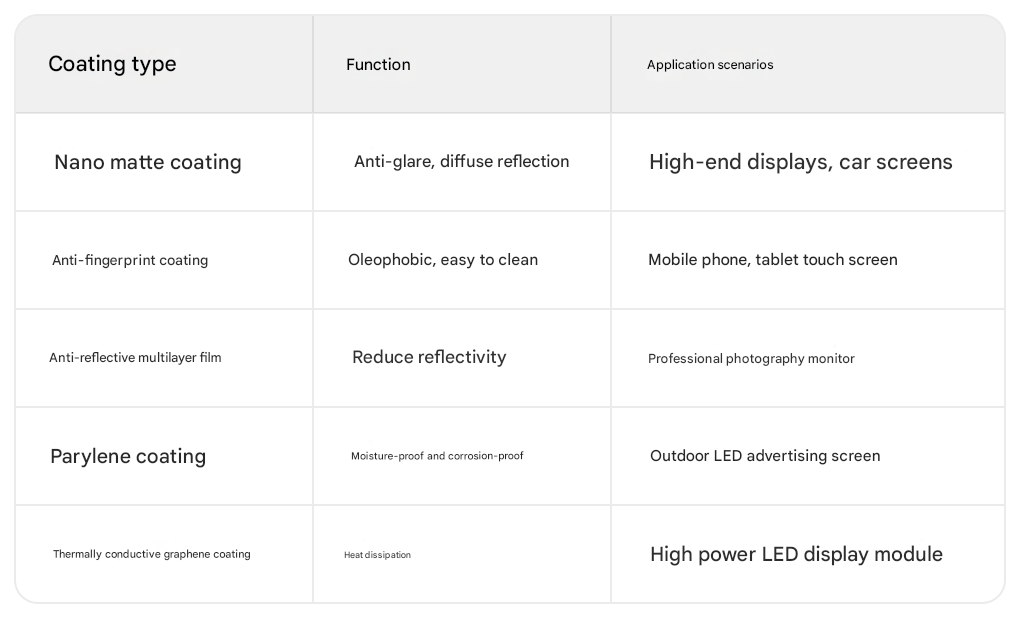

The choice of LED screen coating needs to be customized according to the specific scene requirements (such as outdoor, medical, consumer electronics) and screen type (curved screen, flexible screen, transparent screen). For example, a curved screen may require a high-flexibility coating, while a professional design display requires a high-precision anti-reflective coating. Future trends include the application of innovative technologies such as self-healing coatings and smart color-changing coatings.

● Optical performance

● Reduce glare: It can effectively reduce the reflection of ambient light on the surface of the LED screen, and reduce glare and reflection. For example, in a complex light environment, such as an outdoor advertising screen or an indoor screen under strong light, the use of matte coating solution can enable the audience to see the screen content more clearly without visual interference caused by reflected light.

● Improve contrast: By reducing reflected light, the black area of the screen is made darker, and the contrast between the bright and dark parts is improved. This can make the colors of images and videos more vivid and the layers richer, enhance the visual effect, and bring users a better viewing experience.

● Wide viewing angle optimization: It helps to improve the optical properties of the screen, so that the audience can get a more consistent visual effect when watching from different angles, expand the viewing angle range, and see a clear picture without obvious color difference and brightness changes at multiple angles.

● Protection performance

● Scratch and wear resistance: A hard protective film is formed on the surface of the LED screen, which can effectively prevent scratches and wear that may occur in daily use, such as scratches by rags during cleaning or scratches by sharp objects, extend the service life of the screen, and maintain the integrity of the screen appearance and display effect.

● Dust and waterproof: It has certain hydrophobicity and dust resistance, so that dust, water droplets, etc. are not easy to adhere to the surface of the screen, and it is easy to clean and maintain. This is especially important for outdoor LED screens or screens used in dusty environments, which can reduce the impact of dust and water stains on the display effect.

● Anti-corrosion: It can isolate the contact between air, water vapor and some corrosive substances and the screen surface, prevent the screen from being damaged by chemical reactions such as oxidation and corrosion, especially in some harsh industrial environments or coastal high humidity and high salinity environments, and can protect the electronic components and display materials inside the screen.

● Environmental adaptability

● Anti-fingerprint: It can effectively reduce the fingerprints left when the finger touches the screen, keep the screen surface clean and beautiful, and reduce the need for frequent cleaning for LED screens that often require touch operation, such as touch screen all-in-one machines, and improve the convenience of use.

● Thermal stability: It helps to improve the thermal stability of the screen. When the LED screen generates heat during operation, it can play a certain role in heat dissipation and heat insulation, making the screen temperature distribution more uniform and preventing local overheating, thereby improving the reliability and stability of the screen and extending the service life of the screen.

Ultrasonic spraying technology can be applied to the preparation of coatings such as nano solutions, anti-fingerprint solutions, anti-reflective solutions, parylene solutions, and graphene thermal conductive solutions. It has a wide range of applications and high production efficiency. It is an innovative and high-precision coating technology.

Shanghai Yangmi ultrasonic large-area spraying equipment can be equipped with wide-spray ultrasonic nozzles, and can carry multiple nozzles in parallel at the same time. The automatic conveyor can automatically convey samples, which is particularly suitable for mass production and large-area thin film spraying. Such as fuel cell membrane electrode spraying, various glass coatings, thermal insulation film spraying, AR anti-reflective film spraying, photoresist spraying, transparent conductive film spraying, super hydrophobic coating spraying, etc.