google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The preparation of new energy battery coating by ultrasonic spraying -- New energy -- YMUS ultrasonic spraying

Key words: # new energy # solar cell # lithium battery # fuel cell

In recent years, ultrasonic spraying technology has been widely used in the field of new energy, which can bring better results for the development of new energy field. Ultrasonic spraying technology is to use the vibration effect produced by ultrasonic waves and the inertia of liquid flow to atomize the liquid into droplets, so as to spray on the surface of the substrate to be coated. Due to its characteristics of high spraying uniformity, controllable coating thickness and high spraying efficiency, it provides effective support for the development of new energy field.

1. Application field

1.1 Solar Cells

Solar cells are devices that use semiconductor materials to convert photon energy into electricity, and ultrasonic spraying technology can be used in the preparation of solar cells. The photoelectric conversion efficiency and life of solar cell are directly related to the quality of its surface coating. Ultrasonic spraying technology can uniformly coat a transparent conductive oxide coating on the electrode surface to improve the conversion efficiency of the battery, and can more accurately control the coating thickness, thus reducing the coating cost. In fact, this technology has been successfully applied in the development and production of silicon solar cells, CdTe thin film solar cells, dye sensitized solar cells and other solar cells, and has achieved remarkable results.

1.2 Lithium Battery

A lithium-ion battery is a device that converts chemical energy into electricity or vice versa. Ultrasonic spraying can be used to prepare coatings for anode materials of lithium ion batteries, such as silicon nitride coating prepared by ultrasonic spraying, whose application in anode materials of lithium ion batteries can significantly improve its capacity and cycle performance. Ultrasonic spraying technology is different from the conventional thermal solvent or chemical vapor deposition production method does not need high temperature atmosphere protection, reduce the preparation cost, reduce the waste of air and energy, has the advantages of high efficiency, low cost, environmental protection and so on.

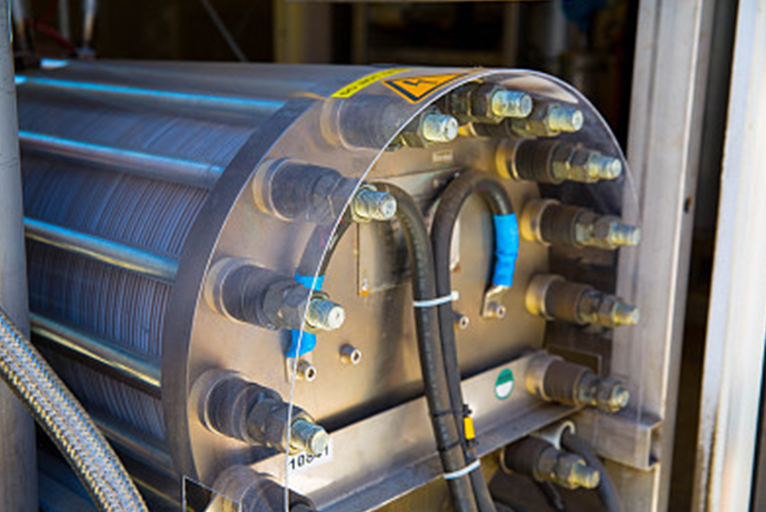

1.3 Fuel Cell

Fuel cell is an electrochemical device that uses hydrogen and oxygen to produce electricity. Ultrasonic spraying technology can be used to prepare coating materials for fuel cells. Using this technique, the liquid material can be sprayed on the electrode surface in a uniform manner, so that the coating is evenly distributed on the electrode, thus providing a better reaction surface.

2. Product advantages

2.1 High spraying uniformity: ultrasonic spraying technology can make the liquid distributed on the electrode surface in an extremely uniform way, smooth and uniform coating, can avoid thick and excessive coating accumulation and influence on the coating surface;

2.2 Precise control of coating thickness: Ultrasonic spraying technology can achieve accurate control of coating thickness. Because this technology can accurately grasp the coating time and spray speed of coating solution, the coating thickness can be well controlled.

2.3 High coating quality: Ultrasonic spraying technology can generate ultrafine droplets and atomize them. Compared with conventional spraying, the droplets are more uniform. It can provide higher coating quality and more uniform coating surface, and has been widely used in many fields such as batteries and solar cells.

3. Coating material

The coating materials commonly used in ultrasonic spraying technology include liquid metal, polymer, nanomaterials, etc., which have excellent physical and chemical properties and a wide range of applications. In addition, ultrasonic spraying technology can also be used for the preparation of lithium ion battery anode materials coating, such as silicon nitride coating, improve the capacity and cycle performance of lithium ion batteries, but also reduce the environmental waste and resource waste in the preparation process.

In the preparation of silicon thin film solar cell, silicone polymer film was prepared by ultrasonic spraying technology. The coating is smooth and transparent, has good oxidation resistance and high electrical properties. Compared with traditional solution methods, ultrasonic spraying technology can better control the coating speed, resulting in a more uniform amount of coating, making solar panels more cost-effective and competitive in manufacturing.

YMUS ultrasonic spraying technology has been widely used in new energy fields, including solar cells, lithium-ion batteries, fuel cells and so on. In addition, ultrasonic spraying technology has the advantages of improving traditional coating technology, such as low coating cost, high utilization rate, environmental protection and so on. The coating prepared by ultrasonic spraying technology can obtain higher performance and better application effect. In order to popularize and apply ultrasonic spraying technology better, it is necessary to carry on the research and practice in coating materials, coating process, improving the stability and life of coating.