google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Photosensitive adhesive is a technology widely used in modern industrial production. The main components of photosensitive adhesive are: film former, photosensitizer, and auxiliary agent. The film former is the main component of the plate film, which determines the film's adhesion and resistance, such as water resistance, solvent resistance, printing resistance, aging resistance, etc. Common film formers include gelatin, protein, PVA (polyvinyl alcohol), etc. and their modified colloids, such as emulsions of PVA and non-water-soluble polymer substances, chemically modified colloids of PVA, and combinations of PVA (or gelatin) and cross-linking agents.

Principle of ultrasonic spraying

The main core of the ultrasonic spraying system is the ultrasonic atomizing nozzle, which can evenly deposit the solution on the surface of the product with the intelligent operating system and liquid supply system. The working principle is to use ultrasonic vibration to convert liquid photosensitive glue into extremely fine droplets, which are evenly dispersed and attached to the surface of the substrate under the action of ultrasonic waves.

Advantages of ultrasonic spraying of photosensitive adhesive

● High coating uniformity: The uniformity of liquid particle distribution after atomization by ultrasonic nozzles is significantly higher than that of traditional two-fluid nozzles, which can reach more than 95%, thus greatly improving the uniformity of the coating after spraying and avoiding the traditional Methods such as spin coating, which causes uneven coating distribution in high-aspect ratio structures due to surface tension issues, can better fill fine areas and prevent problems such as gaps or uneven coating thickness.

● Precisely control the coating thickness: The ultrasonic nozzle has no pressure effect on the liquid. It can control the flow of atomized sprayed coating liquid through a high-precision metering pump such as a syringe pump. The flow control accuracy can reach the level of picolitres per second, thereby realizing coating control. Precise control of layer thickness helps reduce the amount of photosensitive adhesive, reduce costs and improve production efficiency.

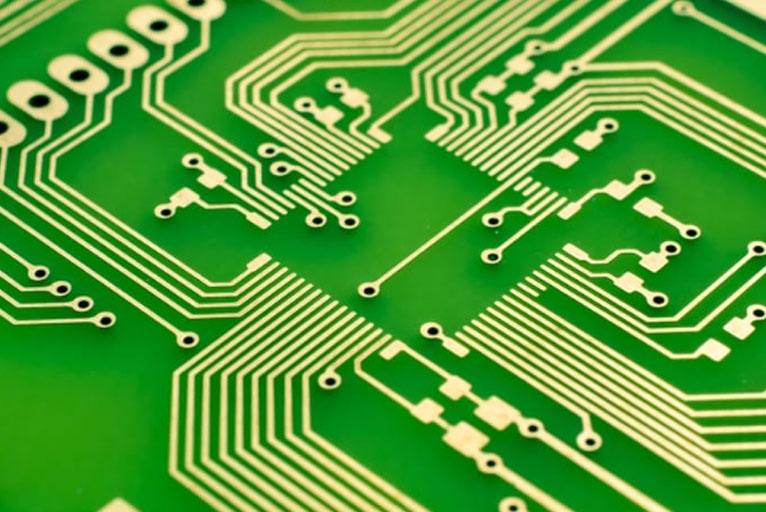

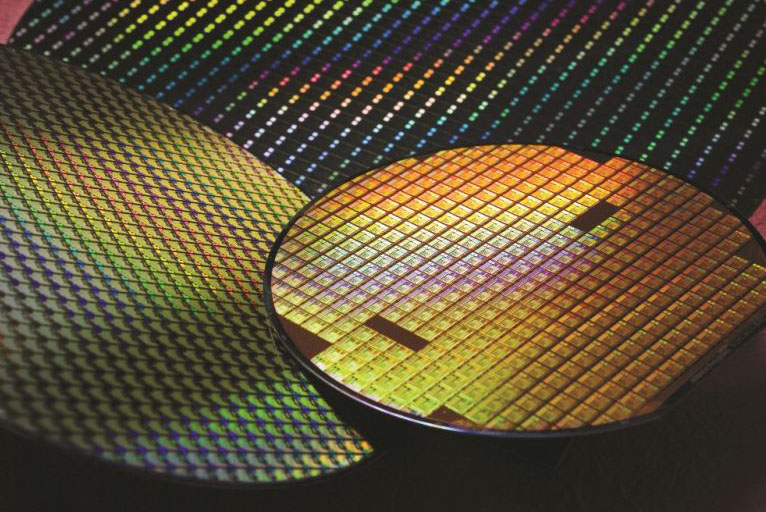

●Wide range of application: Suitable for various types of substrates, such as silicon wafers, glass, ceramics, metals, etc., as well as different types of photosensitive adhesives. It is widely used in many fields such as integrated circuit manufacturing, liquid crystal display, and printed circuit boards. application prospects.

● High material utilization: The process of atomizing the paint does not require gas pressurization. Only a very low carrier gas pressure is applied after atomization to transport the liquid mist, which greatly reduces the liquid rebound caused by high-pressure air spraying by the second fluid. and splashing, the raw material utilization rate is more than 4 times that of ordinary air spraying, and can reach a maximum of more than 90%.

● The nozzle is not easily clogged: The ultrasonic nozzle achieves liquid atomization through ultrasonic oscillation. The atomized particles are determined by the frequency of ultrasonic oscillation. The aperture of the nozzle does not need to be small to achieve fine atomized particles, which reduces the risk of nozzle clogging. risks and reduce equipment maintenance costs.

Application fields:

Microelectronic semiconductors, photovoltaic industry, display panel manufacturing, circuit board PCB, etc.