google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Heart valve film coating - Medical instrument - YMUS ultrasonic spray

Artificial valves are vascular implants, so they need to have good blood compatibility. For interventional biological heart valves, due to the rapid blood flow in the heart, the blood compatibility of biological valves is relatively good, so the probability of thrombosis is small, and interventional biological valves generally do not require long-term use of anticoagulant drugs. Although biological valves have traditionally been considered a good choice for anticoagulation, data analysis in recent years has shown a higher incidence of thrombosis in artificial biological valves, especially with the advent of transcatheter aortic valve replacement, and biological valve thrombosis is a major cause of acute or chronic biological valve degeneration.

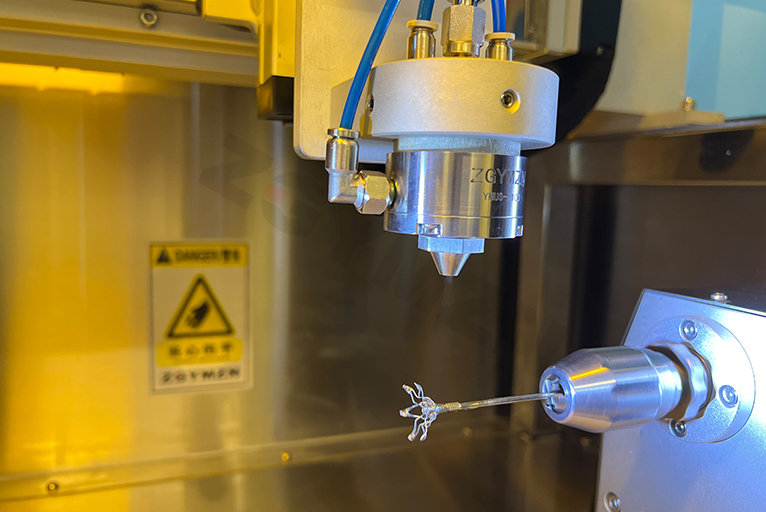

Application of ultrasonic spraying technology in the preparation of artificial heart valve blade coating. In artificial heart valves, coatings with anticoagulant function are essential to reduce thrombosis and extend the service life of artificial heart valves. Ultrasonic spraying technology can achieve uniform and dense coating without damaging the properties of the coating material. In the preparation of anticoagulant artificial heart valve leaf coatings, the following research advances can be used:

● Material selection: Select materials with anticoagulant function as coating materials, common choices include biocompatible polymers and bioactive molecules. These materials can effectively inhibit thrombosis and reduce the expression of mitogen kinase (tissue factor) in the valve lobes.

● Ultrasonic spraying parameters optimization: Adjust the parameters of ultrasonic spraying, such as nozzle distance, spraying speed and spraying frequency, to obtain a uniform and dense coating. Optimizing the parameters can ensure the quality and adhesion of the coating, and improve the anticoagulant function of the coating.

● Coating adhesion: After ultrasonic spraying, it is necessary to ensure that the coating has good adhesion to the surface of the valve lobe. The adhesion of the coating can be improved by adjusting the surface properties of the coating materials, the surface treatment of the valve lobes and the curing treatment after the coating.

The preparation of anticoagulant flap coatings for artificial heart valves remains a challenging area that requires further research and development. At present, YMUS ultrasonic spraying technology has a rich case in the field of medical machinery in this area to improve the quality and stability of the coating in order to provide a viable solution for the clinical application of artificial heart valves.