google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

How to improve the yield of silicon carbide substrate? -- Semiconductor industry -- YMUS Ultrasonic spraying /YMMS megatonic cleaning

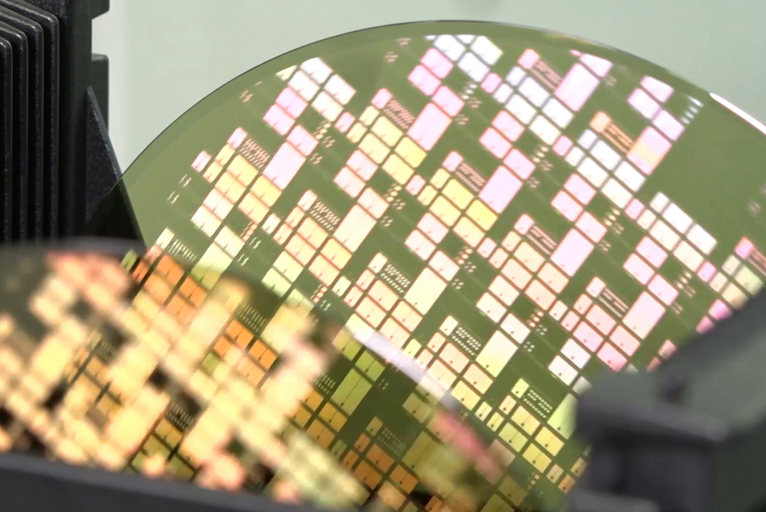

Silicon Carbide Substrate (Silicon Carbide Substrate) because of its excellent high temperature, high pressure, high frequency, radiation and other special properties, is widely used in semiconductor, microelectronics, optoelectronics and other fields, is a high value-added emerging materials. The preparation process of silicon carbide substrate includes substrate growth, substrate cutting, processing and cleaning steps.

1. Material selection of growth substrate:

The selection of growth substrate is the most important step in the process of preparing silicon carbide substrate. At present, the main selection of 4 and 6 inch silicon carbide single crystal substrate as the substrate base material, the selection of high-quality silicon carbide single crystal material is a key step in the preparation of high quality, large size silicon carbide substrate.

2. Quality control of growth substrate:

The substrate quality of growing SIC substrate has a crucial influence on its subsequent physical properties and properties. The automatic seed spray bonding device ensures that the grown silicon carbide substrate is complete, free of impurities such as cracks, oxides or metals, and has a uniform crystal quality.

3. Processing of substrate size:

Practical specifications for silicon carbide substrates range from 2 "to 8", but 2 "and 4" substrate sizes are most common. To ensure accurate dimensional processing technology and aspect ratio control, to ensure the processing of the required high-quality substrate.

4. Substrate surface cleaning:

In order to improve the quality and chemical stability of the crystal, the substrate surface must be cleaned to a dust-free degree before growing the silicon carbide substrate, otherwise the quality and performance of the substrate will be seriously affected. Therefore, the cleaning of the substrate must be very strict, and it is often necessary to use megasonic cleaning equipment for processing in a high-cleanliness aseptic room.

5. Equipment technology:

The preparation of SIC substrate requires high-precision equipment and control system, and it is necessary to fully master the cutting-edge growth technology and related processes. Precision machining, large size growth and efficient resource utilization are one of the main problems in the preparation of SIC substrate at present.

The key and difficult points of preparing SIC substrate are equipment preparation, substrate selection and processing, crystal growth and substrate surface cleaning. Therefore, it requires a high degree of professionalism and technical requirements, and requires comprehensive technical support and rich production experience.

YMUS ultrasonic spraying system

YMMS Megasonic cleaning