google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Hydrogen energy industry chain: alkaline electrolyzed water for hydrogen production (AWE)-new energy-YMUS ultrasonic spraying

Hydrogen production technology is the foundation of the development of hydrogen energy industry in the international community at present, and how to realize clean and efficient hydrogen preparation is one of the major technical problems of hydrogen energy industry that relevant researchers in various countries focus on. At present, hydrogen is mainly produced by electrolysis of water, and there are three main technical routes, namely alkaline electrolysis (AWE), proton exchange membrane (PEM) electrolysis and solid oxide (SOEC) electrolysis.

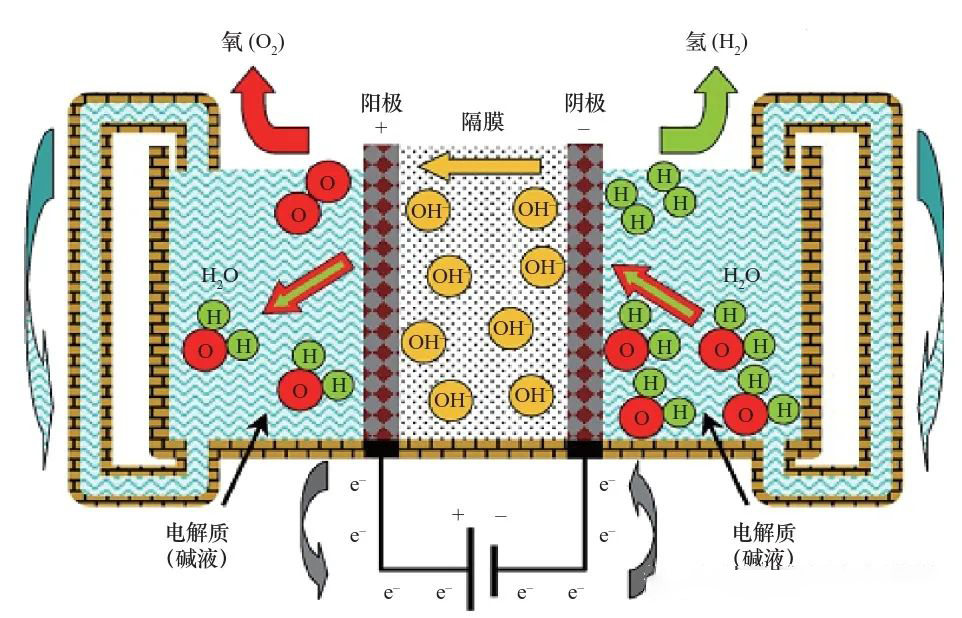

Hydrogen production by alkaline electrolysis of water is a common technology of hydrogen production by water electrolysis. Its basic principle is to decompose water into hydrogen and oxygen by electrolysis of water. In the process of hydrogen production by alkaline electrolysis of water, alkaline electrolyte (such as potassium hydroxide or sodium hydroxide) is usually used as electrolyte to provide ionic conduction.

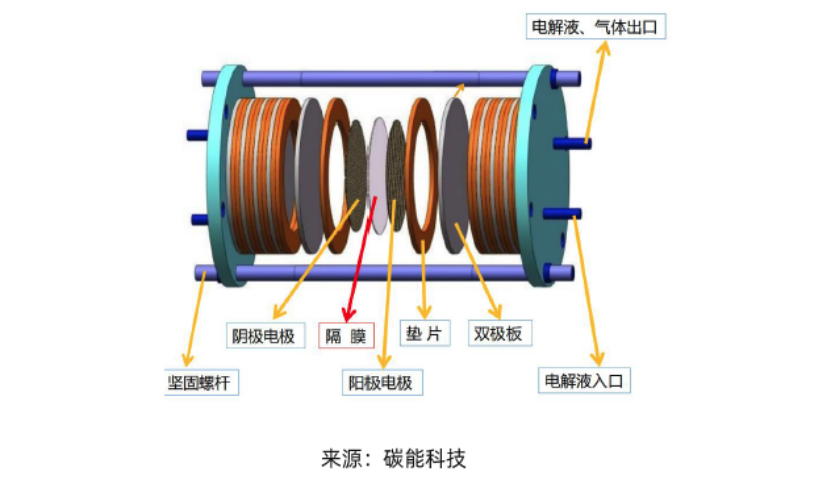

The core of alkaline electrolyzed water hydrogen production system is the main body of alkaline electrolyzer, and the other components include electrode plate and frame, diaphragm, electrode, BOP auxiliary system, etc.

【 polar plate and polar frame 】

The polar plate and the polar frame are the supporting components in the electrolytic cell, which are used to support the electrode and diaphragm and conduct electricity. It is generally made of cast iron metal plate, nickel plate or stainless steel metal plate, which is punched into a mastoid structure by machining and welded with the polar frame and then plated with nickel. There are gas passage holes and liquid passage holes in the polar frame, and the part welded with the main polar plate is called tongue plate, the outermost side of the polar frame is the sealing line area, and the rest is the overlapping area of diaphragm and gasket.

【 Diaphragm 】

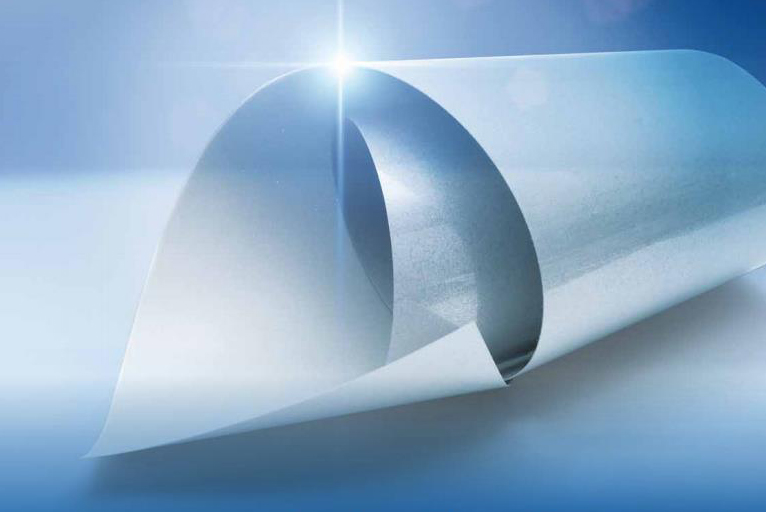

The main function of the diaphragm is to prevent hydrogen and oxygen from mixing. For alkaline electrolyzers, qualified diaphragms shall meet the following requirements:

1, isolate gas molecules, but allow electrolyte ions to pass through;

2. Resistant to the corrosion of high-concentration alkali liquor and the impact of electrolyte and generated gas for a long time;

3, the porosity is as high as possible to reduce the surface resistance, and it is chemically stable at electrolysis temperature and alkaline conditions;

4. The raw materials are easily available, nontoxic and pollution-free, and the waste is easy to handle.

Commonly used diaphragms include asbestos diaphragm, PTFE resin modified asbestos diaphragm, PPS diaphragm, PSF diaphragm and PEEK diaphragm. Different diaphragms have different properties.

Hydrogen production from alkaline electrolyzed water has certain advantages and application prospects in hydrogen energy industry. With the development and progress of water electrolysis hydrogen production technology, ultrasonic spraying oxide electrolytic cell technology and proton exchange membrane electrolysis technology, alkaline electrolysis water hydrogen production technology has been improved qualitatively.

YMUS ultrasonic spraying alkaline electrolyzed water to produce hydrogen diaphragm is a method to prepare alkaline electrolyzed water to produce hydrogen diaphragm by ultrasonic spraying technology. In the traditional hydrogen production by alkaline electrolysis of water, ion exchange membrane is often used as the diaphragm of electrolytic cell to separate anode and cathode and prevent the mixing of hydrogen, oxygen and electrolyte. Ultrasonic spraying technology can prepare uniform and dense films by spraying materials on the substrate by ultrasonic atomization.

Advantages advantages:

1. Uniformity: Ultrasonic spraying technology can realize uniform spraying of materials, so that the prepared diaphragm has uniform thickness and composition, which is beneficial to the stability and efficiency of electrolysis process.

2. Dense film: Ultrasonic spraying technology can prepare dense film, reduce the penetration of hydrogen and oxygen and the mixing of electrolyte, and improve the efficiency and stability of electrolytic cell.