google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

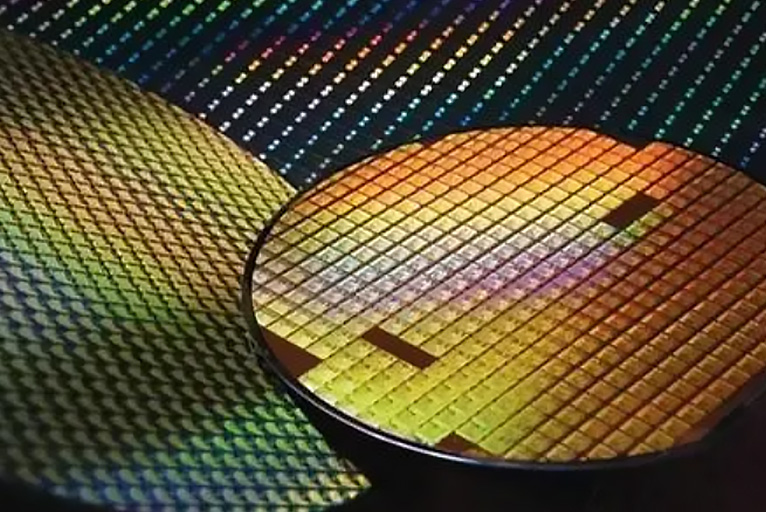

Semiconductor silicon wafer industry barrier - photoresist coating equipment - ultrasonic spraying technology - Shanghai Yangmi ultrasonic spraying

Semiconductor silicon wafer technical parameters are high, the process needs long-term accumulation.

Technical Certification:

Semiconductor core process including monocrystalline silicon, slicing, grinding, polishing process, extension process, such as technical specialization degree is higher, monocrystalline silicon technology is the core technology, and determines the size of the silicon wafer, resistivity, purity, oxygen content, dislocation, crystal defect and other key technical indicators, in the process of crystal growth, we should pay attention to the temperature control and drawing rate. Wafer grinding and polishing process determines wafer thickness, surface finish, surface cleanliness, surface particle size, warp degree and other indicators. The emphasis of epitaxial technology is to ensure the uniformity of thickness and resistivity of epitaxial layer.

Customer Certification:

Chipmakers are wary of bringing in new suppliers and the certification cycle is long. Semiconductor silicon wafer is an important raw material for chip manufacturing enterprises to produce semiconductor products. Chipmakers are wary of bringing in new suppliers. In order to ensure the stability and consistency of product quality, they need to go through a long certification cycle. Typically, chipmakers ask wafer suppliers to supply some silicon wafers for trial production. After the internal certification, the chip manufacturer sends the product to the downstream customer and obtains the customer's approval. Then the silicon chip supplier certification, formally signed the purchase contract.

Capital and scale: The semiconductor silicon wafer industry is a capital intensive industry and needs to reach a certain sales scale to be profitable. Large investments are needed to produce semiconductor silicon wafers on a large scale. At the same time, due to the large investment in fixed assets in the early stage of semiconductor silicon wafer enterprises, they need to form a certain sales scale to make profits, and the early operating pressure is great, and the gross profit margin may be negative.

Semiconductor wafer enterprises need compound talents. The R&D and production process of semiconductor silicon wafers is relatively complex, involving the cross fields of solid state physics, quantum mechanics, thermodynamics, chemistry and so on. Therefore, it needs comprehensive professional knowledge, rich production experience of compound talents.

Shanghai Yangmi ultrasonic spraying system, used in fuel cell proton exchange membrane spraying, thin film solar cells, perovskite, microelectronics, semiconductor, nano new materials, glass coating, biomedical, textile and other fields. We can provide you with more suitable products, services and solutions, which can be effectively applied to your industry area.

Ultrasonic spray systems use advanced spray technology to accurately control flow rate, coating speed, and deposition. Low speed spray molding defines atomized spray as a precise, controlled pattern that avoids overspray when producing very thin and uniform coatings. Spraying using ultrasonic technology has proven to be a reliable and effective way to deposit photoresist on 3D microstructures, thereby reducing equipment failures due to excessive metal exposure to etching agents.