google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of graphene and glass fiber coating - Nanomaterial - YMUS Ultrasonic spraying

Glass fiber coated cloth, glass fiber cloth as the base cloth, through a special coating process, coated with the corresponding chemical raw materials, so that it has a specific purpose. It has been widely used in aerospace, chemical industry, petroleum, large power generation equipment, machinery, metallurgy, electrical insulation, construction and other fields.

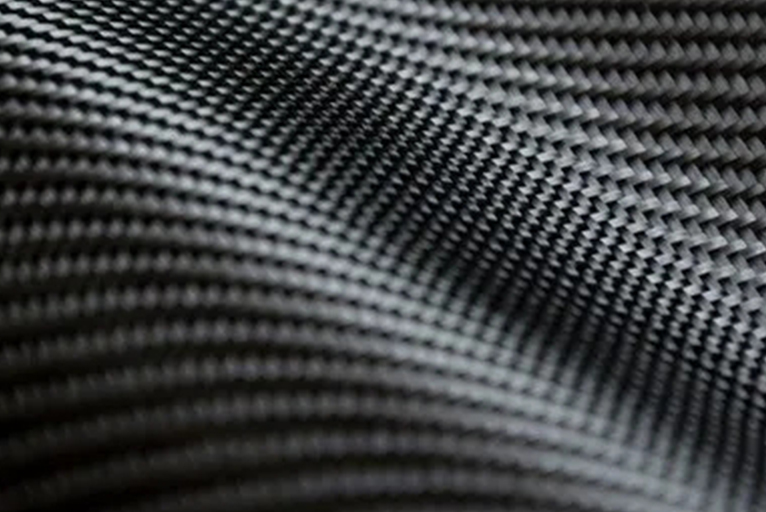

Compared to carbon fiber, glass fiber offers a lower-cost alternative in a wide range of options, from high-quality resin-impregnated laminates for aerospace applications to thermoplastics and injection-molded staple fibers. Both carbon fiber and glass fiber have their own drawbacks. Carbon fiber is a kind of fiber composed of carbon atoms, with light weight, high strength, high modulus, corrosion resistance and other properties, widely used in aviation, aerospace, automotive, sports equipment and other fields. The glass fiber is a fiber composed of glass, with low density, high strength, corrosion resistance, insulation and other advantages, often used in construction, automotive, aquaculture and other fields.

YMUS Ultrasonic spraying technology processes graphene directly onto glass fibers to improve the properties of glass fibers. By precisely controlling the uniformity of the coating and changing the thickness of the thin layer coating on each fiber, the thin layer resistance of the glass fiber fabric can be precisely controlled and adjusted.

Advantages of ultrasonic spraying graphene include:

● Uniformity: Ultrasonic spraying technology can accurately control the uniformity of the coating, helping to obtain a uniform distribution of graphene coatings.

● High efficiency: Ultrasonic spraying operation is simple, spraying speed is fast, and the coating preparation process can be completed in a short time.

● Controllability: By adjusting the spraying parameters and solution concentration, the thickness and quality of the coating can be controlled to meet the specific application needs.

● Wide applicability: Ultrasonic spraying technology is suitable for a variety of substrate materials, and can be combined with other coating technologies to expand its application field.

Graphene-coated glass fiber

The thermal conductivity of the glass fiber is improved by about 100 times after the graphene coating. This feature is ideal for certain applications, such as engines and motors, where excess heat must be effectively removed by composite structures. The thermal conductivity of graphene transfers heat to the environment. This is an extremely important feature, especially when combined with EMI shielding. YMUS ultrasonic spraying technology as a fast, efficient, uniform and suitable for a variety of materials coating preparation technology, has a wide range of applications. With the continuous progress and innovation of technology, it is believed that ultrasonic spraying technology will continue to develop in the future and play a more important role in the field of coating.