google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

China has become the world's leading producer of solar cells. In 2006, the national production of solar cells was 438MW, and in 2007, the national production of solar cells was 1188MW. China has become the world's largest producer of solar cells, surpassing Europe and Japan. Production continued to increase in 2008, reaching 2 million kilowatts.

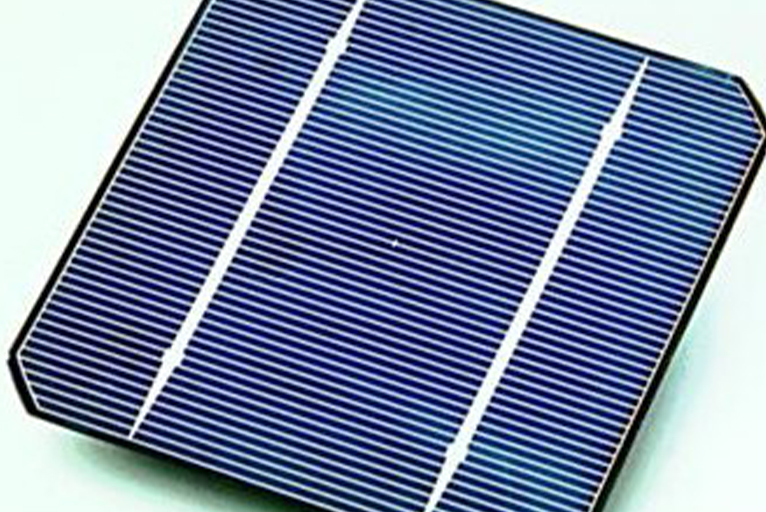

Solar photovoltaic cells, or PV cells, are used to convert light energy from the sun directly into electricity. A large number of silicon-based silicon solar cells are used in the ground PV system, which can be divided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. In terms of energy conversion efficiency and service life, monocrystalline silicon and polycrystalline silicon cells are superior to amorphous silicon cells.

Ultrasonic spraying is a unique atomization technology, which is based on ultrasonic atomization nozzle technology. The sprayed material is first liquid state, liquid can be solution, sol, suspension, etc., coated liquid by ultrasonic atomization device atomized into fine particles, and then by a certain amount of flow carrying gas uniformly coated on the surface of the substrate, thus forming a coating or coating film. Compared with traditional pneumatic two-fluid spraying, ultrasonic atomization spraying has better uniformity, thinner coating thickness and higher precision. At the same time, because the ultrasonic spray nozzle does not need air pressure to atomize, so the use of ultrasonic spraying can greatly reduce the spraying process of raw material splashing, achieve the purpose of saving raw materials, the use of ultrasonic spraying coating is more than 4 times the traditional two fluid spraying.

Ultrasonic sprinkler uses piezoelectric transducer to convert high frequency sound wave into mechanical energy for longitudinal high frequency vibration. The liquid wave extends upward from the tip of the ultrasonic nozzle until it is separated into droplets of uniform size. The secondary molding gas or surrounding air can easily wrap the droplets to the desired shape and speed, enabling a wide variety of spray coatings.

Applied to photovoltaic cell coating:

Ultrasonic spraying technology can successfully deposit anti-reflective layer, TCO coating, buffer layer coating, PEDOT and active layer in the manufacture of thin film and perovskite solar cells. OPV, CIG, CdTE, CzT, perovskite and DSC are some solutions and suspensions that can be deposited in the preparation of thin film solar cells using ultrasonic wet spraying technology. Ultrasonic spraying systems reduce the cost of manufacturing thin-film solar cells while still providing high cell efficiency.

Advantages for photovoltaic cell coating:

1, spraying pattern is easy to form, suitable for the coating application of solar cells.

2. Any shape of spraying can form a uniform micron coating.

3, ultrasonic nozzle is not blocked

4, laser positioning, fast alignment spray position

5, solution conversion rate ≥95%