google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

CFSP-I constant current injection pump Focus on the transmission and distribution of "micro-escalation" fluids. By controlling a set of alternating "extract-injection" execution units and cooperating with the reversing valve, the function of "constant current injection" is realized, which not only retains the transmission accuracy of the micro-injection pump but also realizes the "uninterrupted transmission" of the liquid.

Ultrasonic spray coating

Constant flow supply system

YMUS-HLGY25ml

* Nanometer and micron suspension feeding system

◆ CFSP-I constant current injection pump

Focus on the transmission and distribution of "micro-escalation" fluids. By controlling a set of alternating "extract-injection" execution units and cooperating with the reversing valve, the function of "constant current injection" is realized, which not only retains the transmission accuracy of the micro-injection pump but also realizes the "uninterrupted transmission" of the liquid.

◆ Proprietary system options for liquid delivery and a unique ultrasonic spray feature that can be configured with almost any system. These enhancements can create different spray patterns and deposition characteristics than our standard ultrasonic nozzles.

Scattered advantages

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ In most cases, ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low;

◆ Suitable for the operation of heat-sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;

Technical parameters

◆ Working mode: continuous transmission, quantitative measurement, timed quantitative, timed start and stop

◆ Flow range :0.06mL/min-60mL/min

◆ Filling accuracy :≤ ± 0.05%

◆ Communication interface: RS232, RS485 support Modbus protocol

◆ External control signal: support start/pause, stop, cleaning, reset function

◆ Output interface: indicate liquid output state (collector open output)

◆ Display mode: 4.3-inch industrial grade true color LCD screen

◆ Control mode: touch screen + import button

◆ Maximum pressure of liquid circuit: 0.68Mpa

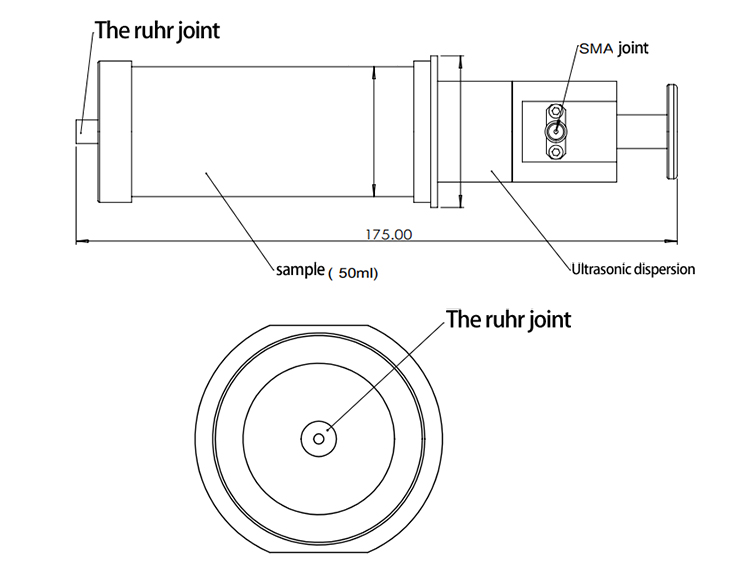

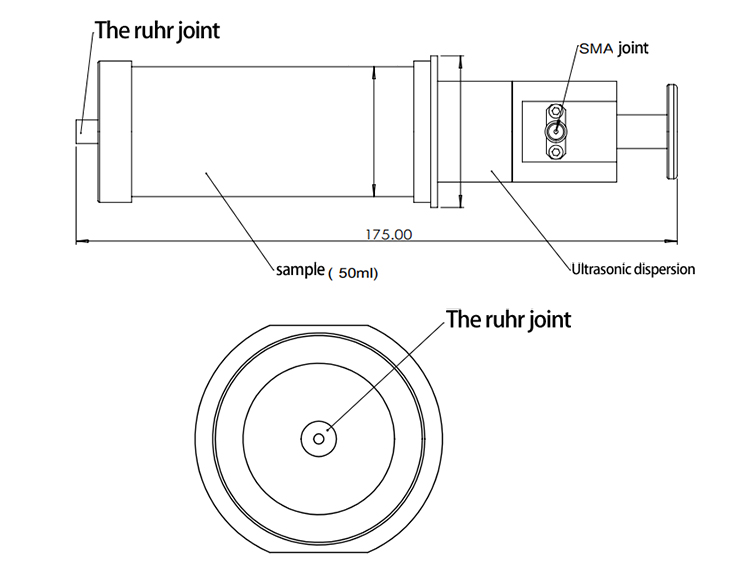

◆ Syringe type: ultrasonic dispersing syringe 25 mL

◆ Input voltage: 220V soil 10%, 50/60Hz

◆ Operating temperature: 15°C-40°C

Application

◆ Nanometer and micron suspension dispersing and mixing;

◆ Ultrasonic and other precision spraying;

◆ In vitro diagnostic instrument liquid sample processing;

◆ Ultrasonic treatment of other liquid materials;

Ultrasonic spray coating

Constant flow supply system

YMUS-HLGY25ml

* Nanometer and micron suspension feeding system

◆ CFSP-I constant current injection pump

Focus on the transmission and distribution of "micro-escalation" fluids. By controlling a set of alternating "extract-injection" execution units and cooperating with the reversing valve, the function of "constant current injection" is realized, which not only retains the transmission accuracy of the micro-injection pump but also realizes the "uninterrupted transmission" of the liquid.

◆ Proprietary system options for liquid delivery and a unique ultrasonic spray feature that can be configured with almost any system. These enhancements can create different spray patterns and deposition characteristics than our standard ultrasonic nozzles.

Scattered advantages

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ In most cases, ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low;

◆ Suitable for the operation of heat-sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;

Technical parameters

◆ Working mode: continuous transmission, quantitative measurement, timed quantitative, timed start and stop

◆ Flow range :0.06mL/min-60mL/min

◆ Filling accuracy :≤ ± 0.05%

◆ Communication interface: RS232, RS485 support Modbus protocol

◆ External control signal: support start/pause, stop, cleaning, reset function

◆ Output interface: indicate liquid output state (collector open output)

◆ Display mode: 4.3-inch industrial grade true color LCD screen

◆ Control mode: touch screen + import button

◆ Maximum pressure of liquid circuit: 0.68Mpa

◆ Syringe type: ultrasonic dispersing syringe 25 mL

◆ Input voltage: 220V soil 10%, 50/60Hz

◆ Operating temperature: 15°C-40°C

Application

◆ Nanometer and micron suspension dispersing and mixing;

◆ Ultrasonic and other precision spraying;

◆ In vitro diagnostic instrument liquid sample processing;

◆ Ultrasonic treatment of other liquid materials;