google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The HIGH FREQUENCY ultrasonic WAVE IS USED TO evenly disperse nano and submicron particles in the sampler and carry out liquid transportation, which can efficiently disperse and transport various nano suspensions and avoid the deposition and agglomeration problems caused by the liquid transportation and spraying process of suspension.

Ultrasonic spray coating

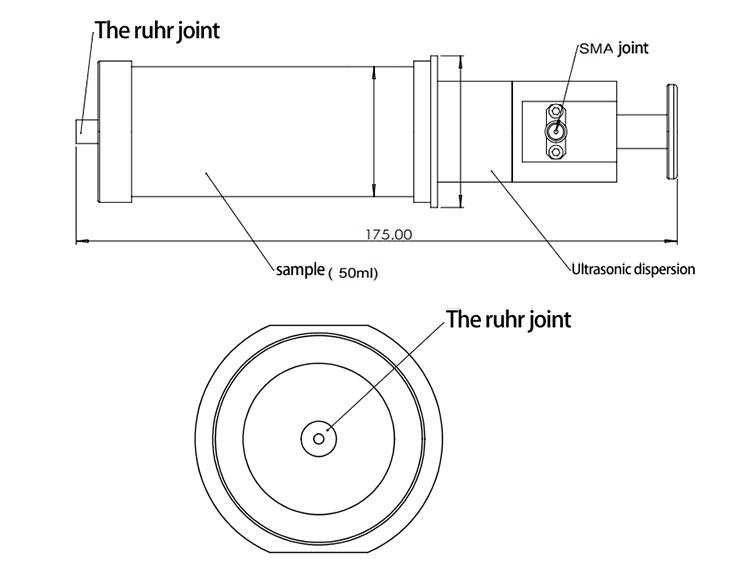

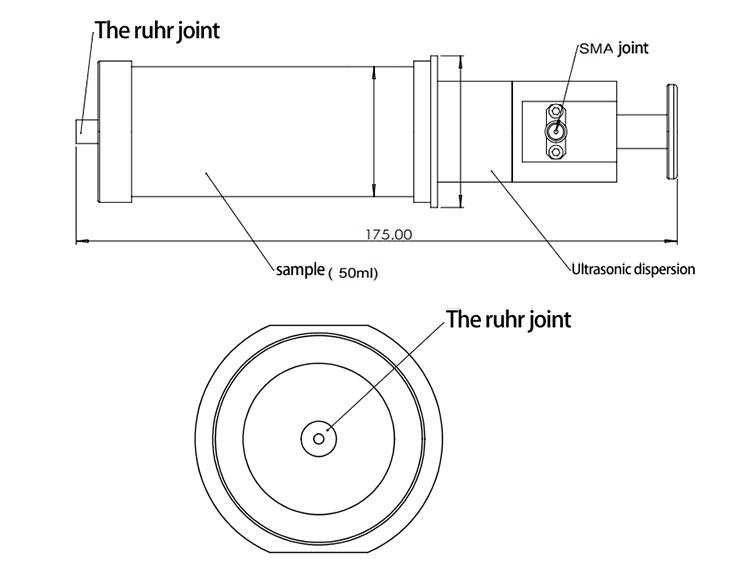

Dispersing syringe

YMUS-FS25ml

* Nanometer and micron suspensions are dispersed and mixed

◆ High frequency ultrasonic transducer is embedded into the injector/injection Nano - and submicron particles in micro containers The rows are evenly dispersed and liquid delivered.

◆ Ultrasonic dispersion is liquid as the medium, in the liquid to add High frequency ultrasonic vibration. Since ultrasound is a mechanical wave, no It is absorbed by the molecule and causes the vibration of the molecule in the process of propagation Movement. Under cavitation effect, that is, high temperature, high pressure, micro jet,Strong vibration and other additional effects of the distance between molecules due to vibration Increase their average distance, and eventually cause the molecules to break up. ultrasonic The instantaneous release of pressure from the wave breaks down the van der Waals between the particles Force, making the particles less likely to stick together.

Scattered advantages

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ In most cases, ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low;

◆ Suitable for the operation of heat-sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;

Technical parameters

◆ Working mode: continuous transmission, quantitative measurement, timed quantitative, timed start and stop

◆ Flow range :0.06mL/min-60mL/min

◆ Filling accuracy :< soil 0.05%

◆ Communication interface: RS232, RS485 support Modbus protocol

◆ External control signal: support start/pause, stop, cleaning, reset function

◆ Output interface: indicate liquid output state (collector open output)

◆ Display mode: 4.3-inch industrial grade true color LCD screen

◆ Control mode: touch screen + import button

◆ Maximum pressure of liquid circuit: 0.68Mpa

◆ Syringe type: ultrasonic dispersing syringe 25 mL

◆ Input voltage: 220V soil 10%, 50/60Hz

◆ Operating temperature: 15°C-40°C

Application

◆ Nanometer and micron suspension dispersing and mixing;

◆ Ultrasonic and other precision spraying;

◆ In vitro diagnostic instrument liquid sample processing;

◆ Ultrasonic treatment of other liquid materials;

Ultrasonic spray coating

Dispersing syringe

YMUS-FS25ml

* Nanometer and micron suspensions are dispersed and mixed

◆ High frequency ultrasonic transducer is embedded into the injector/injection Nano - and submicron particles in micro containers The rows are evenly dispersed and liquid delivered.

◆ Ultrasonic dispersion is liquid as the medium, in the liquid to add High frequency ultrasonic vibration. Since ultrasound is a mechanical wave, no It is absorbed by the molecule and causes the vibration of the molecule in the process of propagation Movement. Under cavitation effect, that is, high temperature, high pressure, micro jet,Strong vibration and other additional effects of the distance between molecules due to vibration Increase their average distance, and eventually cause the molecules to break up. ultrasonic The instantaneous release of pressure from the wave breaks down the van der Waals between the particles Force, making the particles less likely to stick together.

Scattered advantages

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ In most cases, ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low;

◆ Suitable for the operation of heat-sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;

Technical parameters

◆ Working mode: continuous transmission, quantitative measurement, timed quantitative, timed start and stop

◆ Flow range :0.06mL/min-60mL/min

◆ Filling accuracy :< soil 0.05%

◆ Communication interface: RS232, RS485 support Modbus protocol

◆ External control signal: support start/pause, stop, cleaning, reset function

◆ Output interface: indicate liquid output state (collector open output)

◆ Display mode: 4.3-inch industrial grade true color LCD screen

◆ Control mode: touch screen + import button

◆ Maximum pressure of liquid circuit: 0.68Mpa

◆ Syringe type: ultrasonic dispersing syringe 25 mL

◆ Input voltage: 220V soil 10%, 50/60Hz

◆ Operating temperature: 15°C-40°C

Application

◆ Nanometer and micron suspension dispersing and mixing;

◆ Ultrasonic and other precision spraying;

◆ In vitro diagnostic instrument liquid sample processing;

◆ Ultrasonic treatment of other liquid materials;