google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

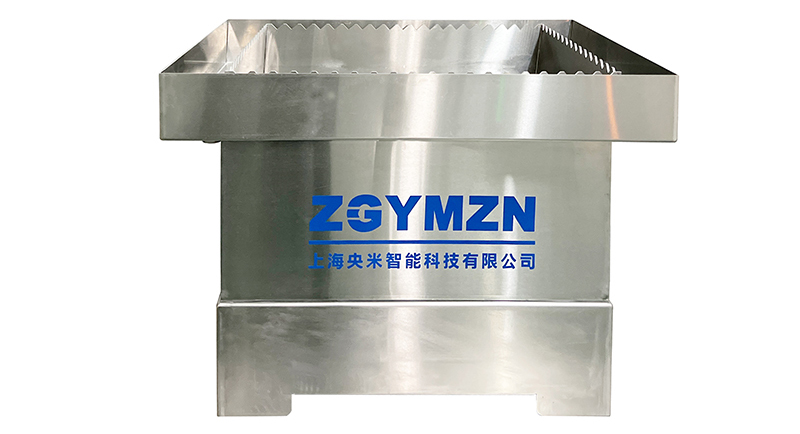

Megasonic Cleaning Systems, cleaning uniform, small damage is basically no, most suitable for semiconductor wafers and HDD parts of ultra-precision cleaning. Acceleration and chemistry are used to remove particles below the micron level. Various shapes of vibration plates can be set corresponding to different cleaning objects and devices. The material of the liquid receiving part corresponds to the cleaning fluid and cleanliness, and is made of stainless steel, tantalum, quartz and other materials.

Megasonic Cleaning Systems

Tank type

YMMS

● Megabyte vibration plate, used for assembling groove type Megabyte cleaning equipment;

● 1MHz ultra high frequency ultrasound, more refined sound processing effect;

● Uniform mega sound field, vibration plate surface sound intensity can exceed 5W/cm2;

● Advanced quartz and sapphire coupling technology, no risk of impurities falling off;

● Ultra-low acoustic cavitation effect, does not damage the surface of the device;

● High corrosion resistance, can resist all kinds of acid and alkali solutions and organic solvents;

Characteristics

Megasonic Cleaning Systems does not produce strong cavitation effect, which can avoid damage to the surface of the cleaning object and residual pollutants in the cleaning process. Megabound cleaning efficiency is high, time is short, the use of cleaning agent concentration is low, the consumption of chemical reagents is less, so the level of harm to the environment is low.

Advantage

● can be directly installed to the bottom of the cleaning tank megabanking plate, convenient for secondary development;

● MeAE sound field distribution is uniform, improve cleaning uniformity;

● Very low ultrasonic cavitation effect, will not cause damage to the device surface;

● High-power Megabyte acoustic transducer, the sound intensity of the plate surface can reach more than 5W/cm2;

● Quartz or sapphire matching layer technology, no risk of impurities falling off the device;

● Can be comprehensive non-metallic high anticorrosion material, adapt to all kinds of acid and alkali and organic solvents;

● Unique transducer fitting technology, higher stability and durability;

● The third generation of semiconductor technology megabound generator, fully realize digital high frequency high power drive;

Device Features

Input power: 600-1200W;

Frequency: 1 MHZ;

Effective cleaning area: 135-160mm;

Megabyte vibration plate, used for assembling groove type Megabyte cleaning equipment;

1MHz ultra high frequency mega sound wave, finer sound processing effect;

The sound intensity on the surface of the plate can exceed 5W/cm2;

Advanced quartz and sapphire coupling technology, no risk of impurities falling off;

Ultra-low acoustic cavitation effect, no damage to device surface;

High anticorrosion, can resist all kinds of acid and alkali solutions and organic solvents;

Megasonic emission sound field distribution is uniform, improve cleaning uniformity;

Can be comprehensive non-metallic high anticorrosion material, suitable for all kinds of acid and alkali and organic solvents;

Unique transducer fitting technology for higher stability and durability;

Technical parameters

● Input power: 600-1200W

● Frequency: 1MHz

● Effective cleaning area: 135-280mm

● Material: electric polishing surface

● Weight: 3-7kg

● Corresponding wafer size: 6-8inch

● Liquid temperature range: 5-80℃

● Sensor: PZT

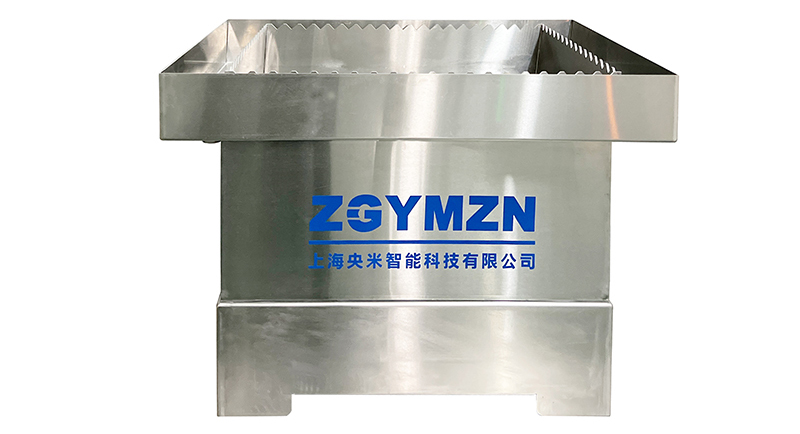

Megasonic Cleaning Systems

Tank type

YMMS

● Megabyte vibration plate, used for assembling groove type Megabyte cleaning equipment;

● 1MHz ultra high frequency ultrasound, more refined sound processing effect;

● Uniform mega sound field, vibration plate surface sound intensity can exceed 5W/cm2;

● Advanced quartz and sapphire coupling technology, no risk of impurities falling off;

● Ultra-low acoustic cavitation effect, does not damage the surface of the device;

● High corrosion resistance, can resist all kinds of acid and alkali solutions and organic solvents;

Characteristics

Megasonic Cleaning Systems does not produce strong cavitation effect, which can avoid damage to the surface of the cleaning object and residual pollutants in the cleaning process. Megabound cleaning efficiency is high, time is short, the use of cleaning agent concentration is low, the consumption of chemical reagents is less, so the level of harm to the environment is low.

Advantage

● can be directly installed to the bottom of the cleaning tank megabanking plate, convenient for secondary development;

● MeAE sound field distribution is uniform, improve cleaning uniformity;

● Very low ultrasonic cavitation effect, will not cause damage to the device surface;

● High-power Megabyte acoustic transducer, the sound intensity of the plate surface can reach more than 5W/cm2;

● Quartz or sapphire matching layer technology, no risk of impurities falling off the device;

● Can be comprehensive non-metallic high anticorrosion material, adapt to all kinds of acid and alkali and organic solvents;

● Unique transducer fitting technology, higher stability and durability;

● The third generation of semiconductor technology megabound generator, fully realize digital high frequency high power drive;

Device Features

Input power: 600-1200W;

Frequency: 1 MHZ;

Effective cleaning area: 135-160mm;

Megabyte vibration plate, used for assembling groove type Megabyte cleaning equipment;

1MHz ultra high frequency mega sound wave, finer sound processing effect;

The sound intensity on the surface of the plate can exceed 5W/cm2;

Advanced quartz and sapphire coupling technology, no risk of impurities falling off;

Ultra-low acoustic cavitation effect, no damage to device surface;

High anticorrosion, can resist all kinds of acid and alkali solutions and organic solvents;

Megasonic emission sound field distribution is uniform, improve cleaning uniformity;

Can be comprehensive non-metallic high anticorrosion material, suitable for all kinds of acid and alkali and organic solvents;

Unique transducer fitting technology for higher stability and durability;

Technical parameters

● Input power: 600-1200W

● Frequency: 1MHz

● Effective cleaning area: 135-280mm

● Material: electric polishing surface

● Weight: 3-7kg

● Corresponding wafer size: 6-8inch

● Liquid temperature range: 5-80℃

● Sensor: PZT