google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

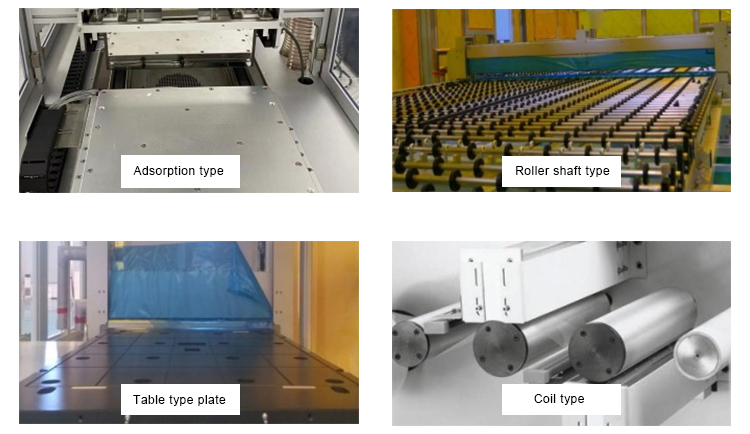

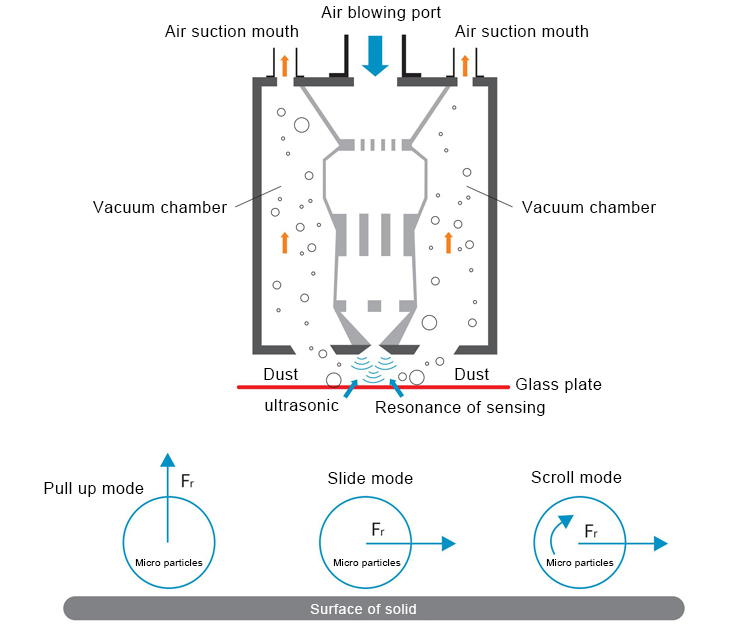

Dry ultrasonic dust removal equipment (USC), through the blower to ultrasonic cavity to provide 14-20Kpa of clean gas to produce ultrasonic, ultrasonic energy and vibration, by pulling up, rolling and sliding three modes of movement (single - or mixed) to separate the dust particles from the surface of the material, to achieve the purpose of dust removal, is an efficient, safe and clean dry dust removal equipment.

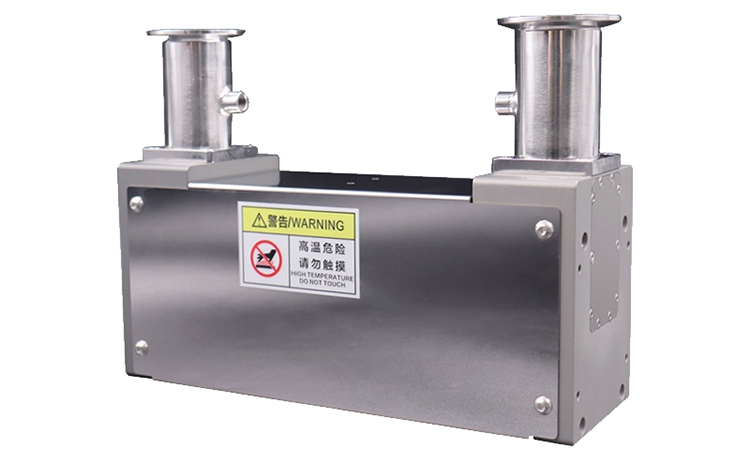

Ultrasonic dry cleaning machine

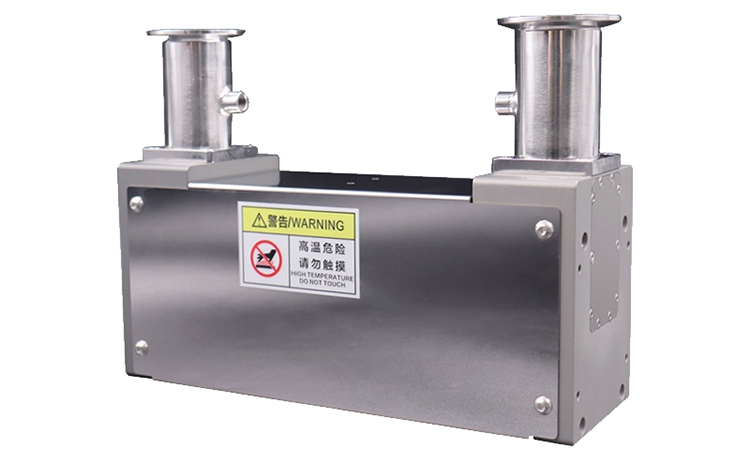

U-shaped outlet pipe

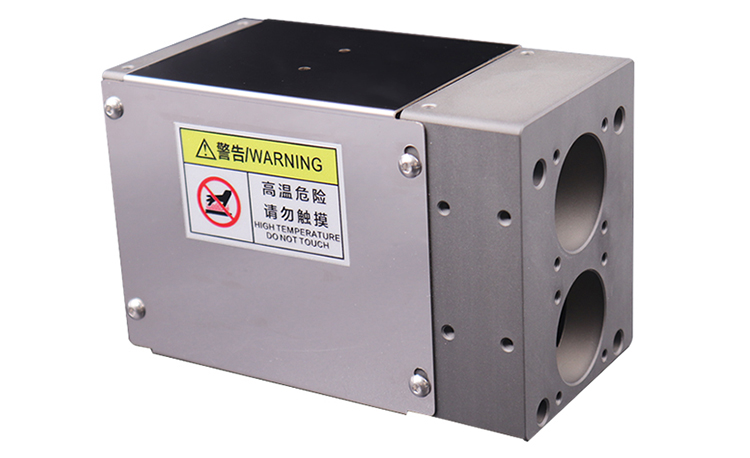

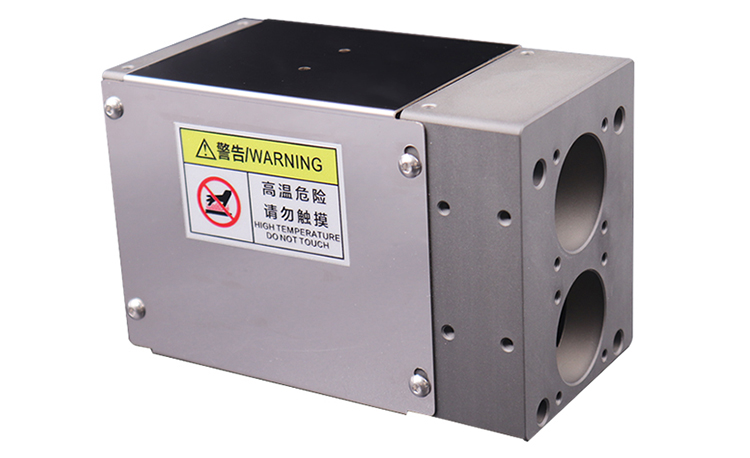

C-shaped outlet pipe

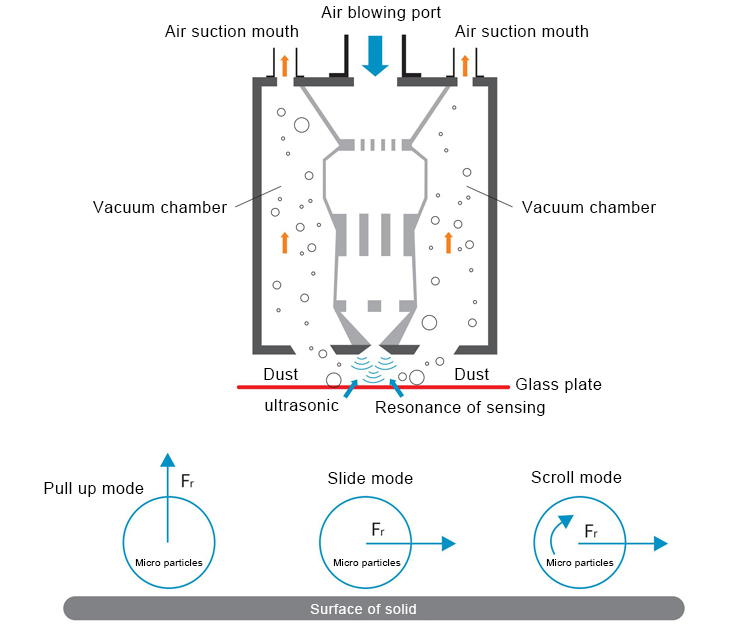

Working Mechanism

Dry ultrasonic dust removal equipment (USC), through the blower to ultrasonic cavity to provide 14-20Kpa of clean gas to produce ultrasonic, ultrasonic energy and vibration, by pulling up, rolling and sliding three modes of movement (single - or mixed) to separate the dust particles from the surface of the material, to achieve the purpose of dust removal, is an efficient, safe and clean dry dust removal equipment.

Principle of product

The blower provides 8-16Kpa clean gas to the ultrasonic chamber to generate ultrasonic waves. The ultrasonic energy and vibration can be used to separate the dust particles from the material surface and achieve the purpose of dust removal. It is an efficient, safe and clean dry dust removal method.

Product Advantages

● Product no damage: non-contact dust removal, does not produce any physical and chemical changes, does not cause product damage;

● Generator never fails: long temperature, no maintenance, no wearing parts;

● Green and pollution-free: closed-loop system, with internal circulation of clean air as the medium, will not destroy the air balance of clean workshop, will not cause two times of pollution;

● Simple and convenient: because the air is the medium of dust removal, so there is no need for water, solvent, drying and other processes;

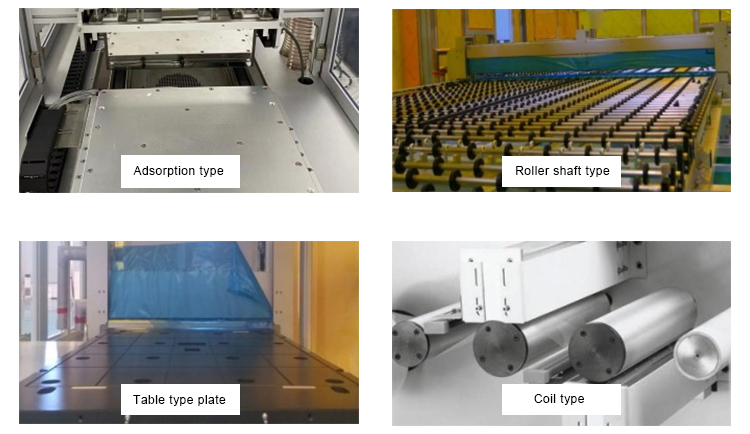

● Custom dust removal width: can be customized according to the size of the product design suitable processing width;

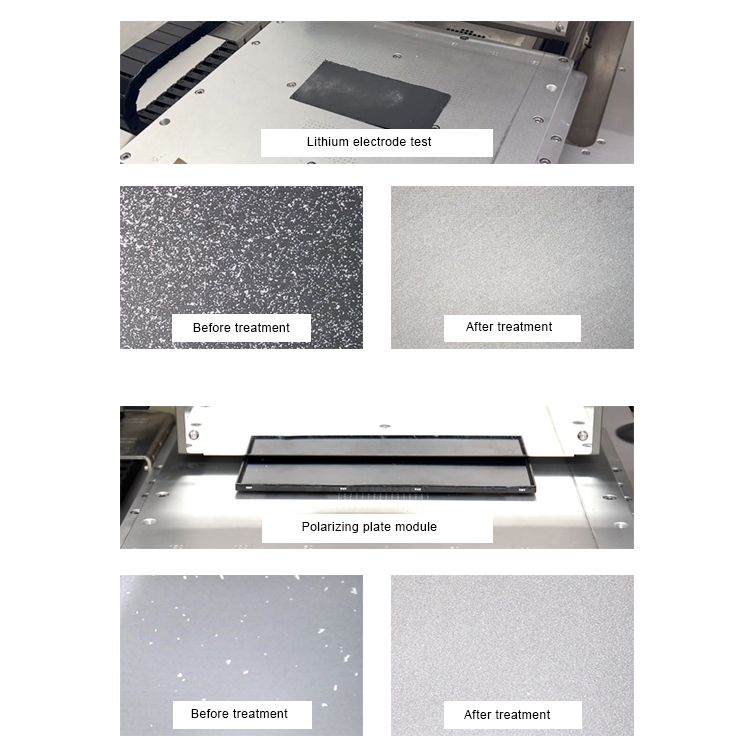

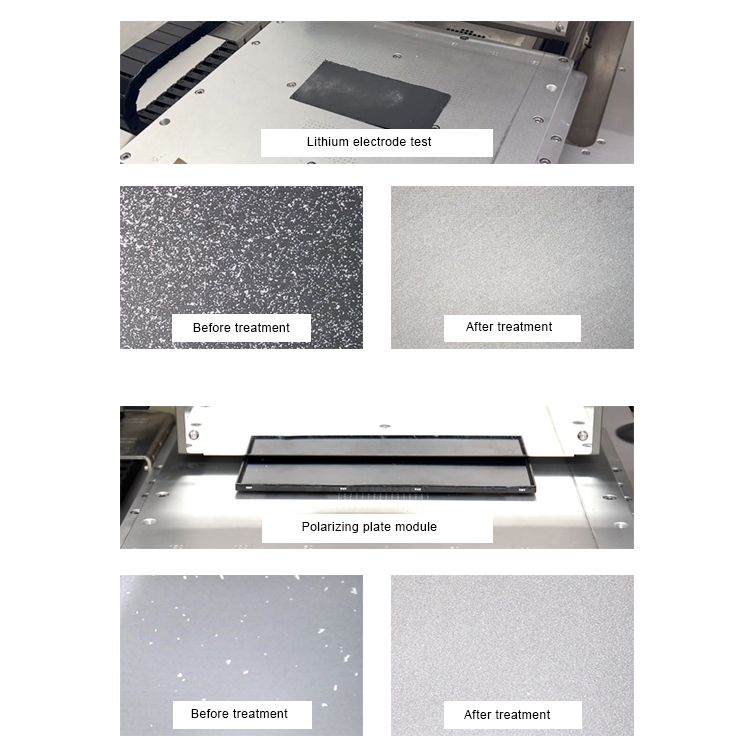

Industry Cases

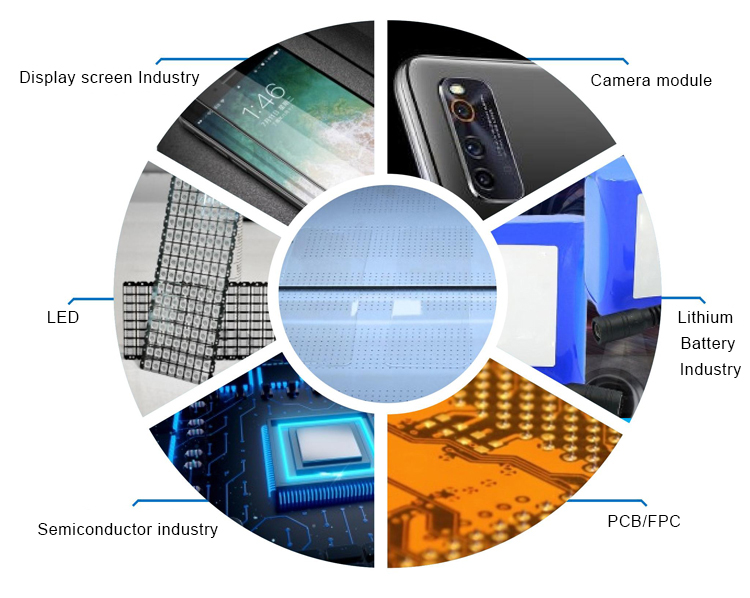

Application

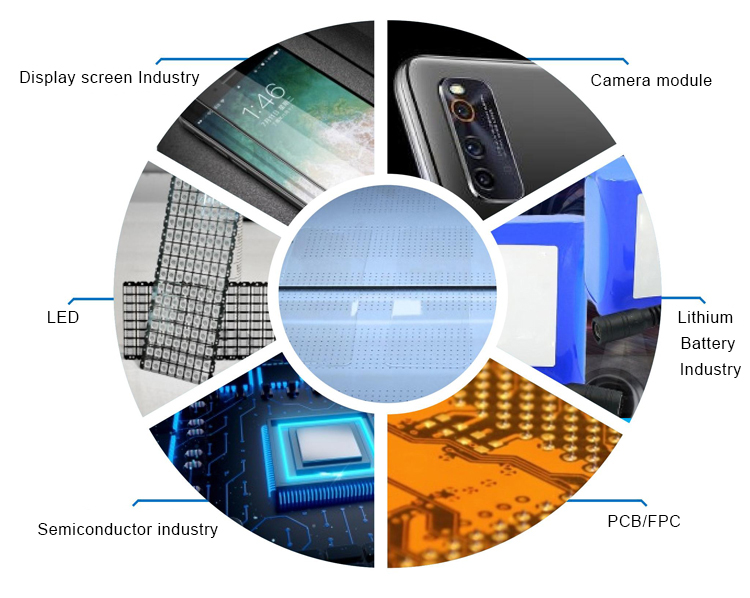

USC can quickly and effectively remove the dust particles on the surface of products to ensure the quality of subsequent spraying, coating, adhesive, welding, packaging and other processes. Greatly reduce the failure rate, improve the product yield.

Ultrasonic dry cleaning machine

U-shaped outlet pipe

C-shaped outlet pipe

Working Mechanism

Dry ultrasonic dust removal equipment (USC), through the blower to ultrasonic cavity to provide 14-20Kpa of clean gas to produce ultrasonic, ultrasonic energy and vibration, by pulling up, rolling and sliding three modes of movement (single - or mixed) to separate the dust particles from the surface of the material, to achieve the purpose of dust removal, is an efficient, safe and clean dry dust removal equipment.

Principle of product

The blower provides 8-16Kpa clean gas to the ultrasonic chamber to generate ultrasonic waves. The ultrasonic energy and vibration can be used to separate the dust particles from the material surface and achieve the purpose of dust removal. It is an efficient, safe and clean dry dust removal method.

Product Advantages

● Product no damage: non-contact dust removal, does not produce any physical and chemical changes, does not cause product damage;

● Generator never fails: long temperature, no maintenance, no wearing parts;

● Green and pollution-free: closed-loop system, with internal circulation of clean air as the medium, will not destroy the air balance of clean workshop, will not cause two times of pollution;

● Simple and convenient: because the air is the medium of dust removal, so there is no need for water, solvent, drying and other processes;

● Custom dust removal width: can be customized according to the size of the product design suitable processing width;

Industry Cases

Application

USC can quickly and effectively remove the dust particles on the surface of products to ensure the quality of subsequent spraying, coating, adhesive, welding, packaging and other processes. Greatly reduce the failure rate, improve the product yield.