google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

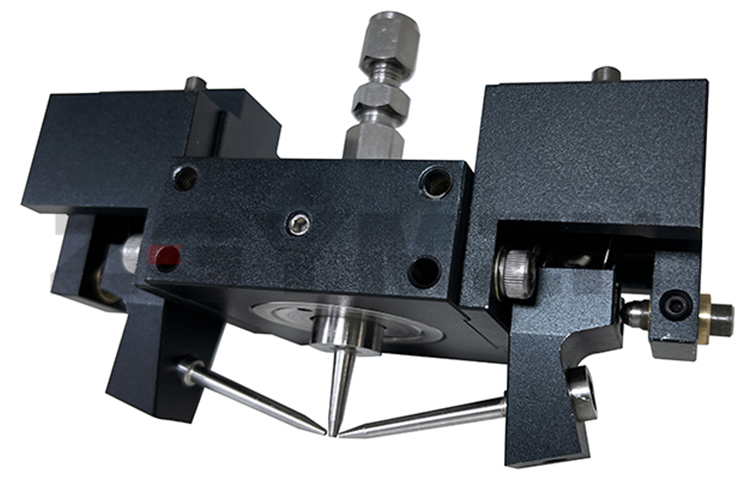

Micro ultrasonic spray nozzle, through the special way of liquid and air supply, so that the ultrasonic spray nozzle has a smaller spray area and more accurate spray flow. The micro ultrasonic atomizer is especially suitable for the spraying and preparation of small area film coating such as drug scaffold spraying, drug balloon spraying and biosensor spraying

Ultrasonic spray coating

Micro type nozzle

YMUS-X

Device Features

◆ Minimal area spraying, minimal flow: spraying width 1-2mm, minimum flow 0.005ml/min;

◆ Uniform coating: uniformity >95%;

◆ Save raw material: Raw material utilization rate up to 85%, 4 times the traditional two-fluid spraying;

◆ Fine atomizing particles, atomizing particles uniform;

◆ Not easy to block the nozzle;

◆ Can achieve high precision, high control spraying;

Application

◆ New energy: fuel cell, membrane electrode, thin film solar cell, proton exchange membrane, etc;

◆ Medical treatment: balloon catheter, blood collection syringe, stent, biosensor, microfluidic chip, etc;

◆ Microelectronics semiconductor electronics: flux, photoresist coating, conductive coating, hydrophilic and hydrophobic coating, etc;

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresistance film, transparent conductive, etc;

◆ Nanotechnology: carbon nanotube, polymer fiber, nano-film, etc;

Ultrasonic spray coating

Micro type nozzle

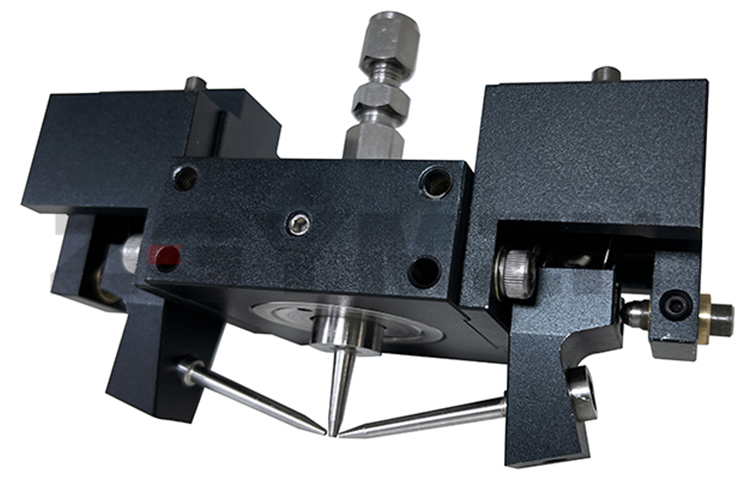

YMUS-X

Device Features

◆ Minimal area spraying, minimal flow: spraying width 1-2mm, minimum flow 0.005ml/min;

◆ Uniform coating: uniformity >95%;

◆ Save raw material: Raw material utilization rate up to 85%, 4 times the traditional two-fluid spraying;

◆ Fine atomizing particles, atomizing particles uniform;

◆ Not easy to block the nozzle;

◆ Can achieve high precision, high control spraying;

Application

◆ New energy: fuel cell, membrane electrode, thin film solar cell, proton exchange membrane, etc;

◆ Medical treatment: balloon catheter, blood collection syringe, stent, biosensor, microfluidic chip, etc;

◆ Microelectronics semiconductor electronics: flux, photoresist coating, conductive coating, hydrophilic and hydrophobic coating, etc;

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresistance film, transparent conductive, etc;

◆ Nanotechnology: carbon nanotube, polymer fiber, nano-film, etc;