google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of AF, AG, AR coatings on 3D glass surface of mobile phone cover - Ultrasonic spraying

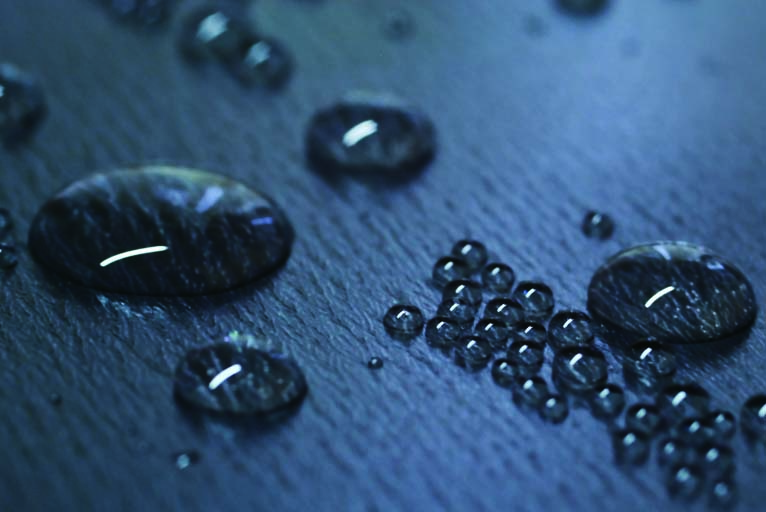

AF —— Anti-fingerprint, anti-fingerprint;

AF anti-fouling and anti-fingerprint glass uses the lotus leaf principle to coat a layer of nano-chemical materials on the outer surface of the glass, which reduces the surface tension of the glass to a minimum and reduces the contact area between dust and the glass surface by 90%. It has the characteristics of high hydrophobicity, oil resistance and anti-fingerprint, allowing the video glass panel to remain smooth and bright for a long time. It is generally coated with a high-precision solution atomization, and ultrasonic spraying equipment can be used.

AF coating product features:

1) Anti-fouling: prevent fingerprints and oil stains from adhering and easy to wipe off;

2) Anti-scratch: smooth surface, comfortable to touch, not easy to scratch;

3) Thin film layer: excellent optical performance, does not change the original texture;

4) Wear resistance: has true wear resistance;

● Application areas: mobile phones, tablets, TVs, LEDs and other glass;

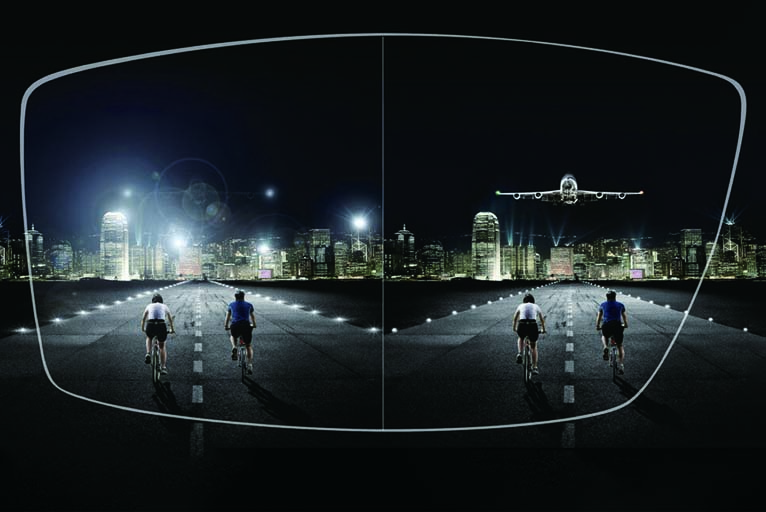

AR —— Anti-reflection, anti-reflection and anti-transmission

Anti-reflection film is also called anti-reflection film. Its main function is to reduce or eliminate the reflected light from the surface of lenses, prisms, plane mirrors, etc., thereby increasing the light transmittance of these components and reducing or eliminating the stray light of the system. Anti-reflection film is based on the wave nature and interference phenomenon of light. If two light waves with the same amplitude and wavelength are superimposed, the amplitude of the light wave is enhanced; if the two light waves have the same origin and the path difference, if these two light waves are superimposed, they will cancel each other out. Anti-reflection film uses this principle to coat the surface of the lens with anti-reflection film (AR-coating), so that the reflected light generated by the front and back surfaces of the film layer interfere with each other, thereby canceling out the reflected light and achieving the effect of anti-reflection. Generally, the coating is prepared by ultrasonic spraying technology.

AR coating product features:

1) High transmittance: Nano-level optical coating technology can increase the transmittance of ultra-clear glass by 2-3%;

2) Durable: Functionality is maintained for a long time;

3) Anti-scratch hardness: After coating, the hardness can be increased by 1H;

4) Easy to clean: The amount can be reduced by 80%, and it is very easy to clean;

● Application areas: front and rear windshields of automobiles, solar photovoltaic industry (solar panels), etc.;

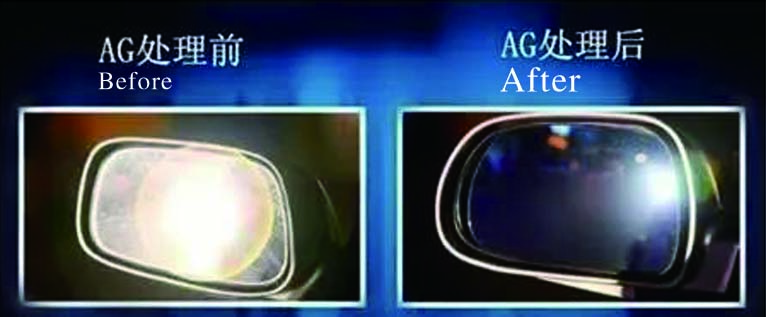

AG —— Anti-glare glass

The principle is to process high-quality glass sheets on both sides or one side through special processing. This makes it have a lower reflectivity than ordinary glass, and the light reflectivity is reduced from 8% to less than 1%. The technology creates a clear and transparent visual effect, allowing viewers to experience a better sensory vision.

AG coating product features:

1) Reflect infrared rays: reduce the transmittance of infrared rays on the glass surface to reduce the infrared light entering the room;

2) Enhance light transmittance: enhance the transmittance of other light sources while reflecting infrared rays, without affecting the indoor lighting effect;

3) Anti-glare: change the visual stimulation of reflected strong light to the observer through diffuse reflection (the essence of AG coating);

● Application areas: electronic whiteboards, DLP/LCD touch screens, DLP/LCD TV walls, electronic product windows, etc.;

Shanghai Yangmi ultrasonic spraying AF, AG, AR solutions uses high-precision ultrasonic atomizing nozzles, high-frequency vibration to refine the slurry and spray it evenly on the substrate, accurately controlling the coating thickness and uniformity to achieve multi-layer coating. The atomized particles can reach nanometer level and are evenly coated on the product surface to prepare a uniform film layer.