google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Fuel cell bipolar materials and preparation——Proton exchange membrane fuel cells——YMUS ultrasonic spraying

The development of proton exchange membrane fuel cells shows its potential as a clean, efficient and reliable power source. As one of the key components of PEM⁃FC, the bipolar plate provides electrical connections, transport of reaction gas, emission of reaction heat and removal of by-products, but is also one of the main factors limiting the cost of PEMFC. According to the different materials, it can be divided into metal bipolar plate, graphite bipolar plate and composite bipolar plate. Due to its excellent mechanical and physical properties, metal bipolar plate has a strong cost advantage compared with non-porous graphite and composite materials, and has attracted much attention in passenger car applications, but its manufacturing process and corrosion resistance are the main concerns of metal bipolar plate. In the future, the development of excellent corrosion resistance and conductivity coatings or new bipolar metal materials will greatly promote the application of PEMFC in the field of passenger vehicles.

Hydrogen energy is considered as the most suitable energy source, and proton exchange membrane fuel cells based on hydrogen energy become the most potential energy charging device due to its advantages of high efficiency, zero emission and low working temperature.

From the perspective of the coating process route, the ultrasonic spraying process is applied to the proton exchange membrane fuel cell coating. Ultrasonic spraying technology is an ideal surface modification technology with high purity, good compactness, cost saving, uniform spraying, solid binding between the coating and the substrate, and the coating is not affected by the substrate material.

Proton exchange membrane

Ultrasonic precision spraying preparation

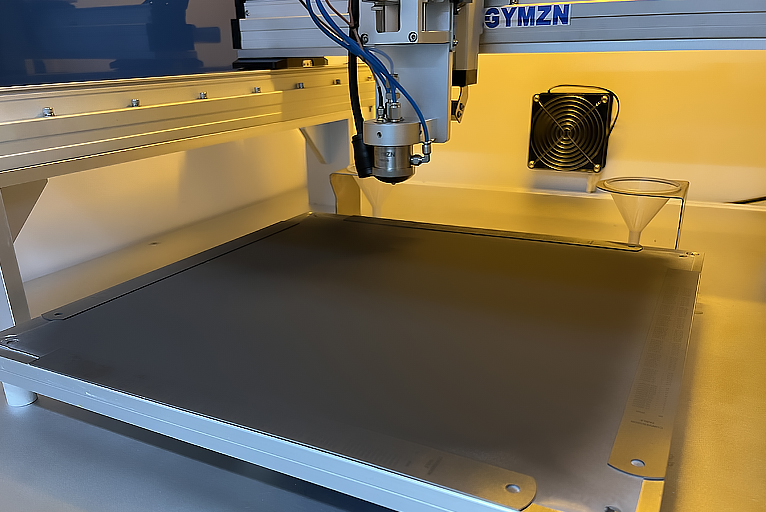

YMUS-ZS400Smart ultrasonic spraying equipment, which can prepare nanometer coating thickness, automatic cleaning, automatic rehydration, on-line drying, multi-track implantation and multi-frequency sprinkler interchangeability.

YMUS-ZS400