google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of fuel cell membrane electrode -- Fuel cell proton exchange membrane -- YMUS ultrasonic spraying

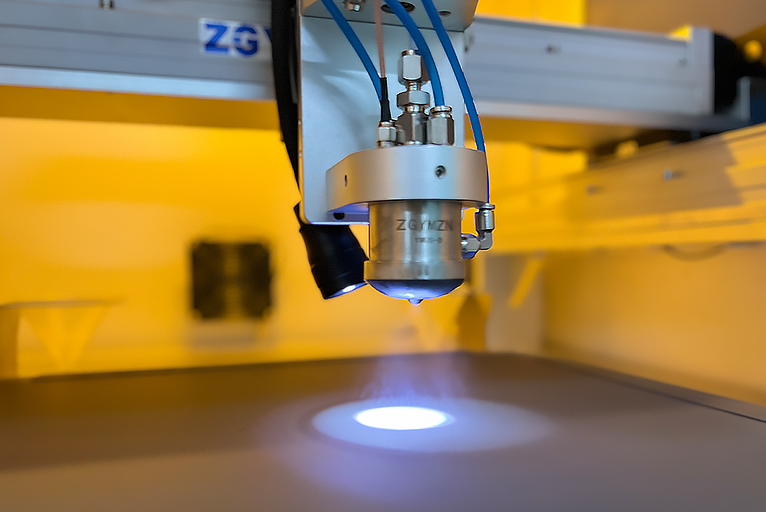

Ultrasonic spraying is a new MEA preparation method developed in recent years. The membrane electrode prepared by ultrasonic spraying has high automation, high efficiency and low manufacturing cost, which can meet the requirements of quantitative production. The utilization rate of platinum in ultrasonic sprayed films can be up to 90%, reducing material consumption, thus saving the use of expensive catalyst ink. Shanghai Yangmi focuses on the research and development of ultrasonic application technology, launched the ultrasonic spraying equipment, through the ultrasonic spraying thin film electrode.

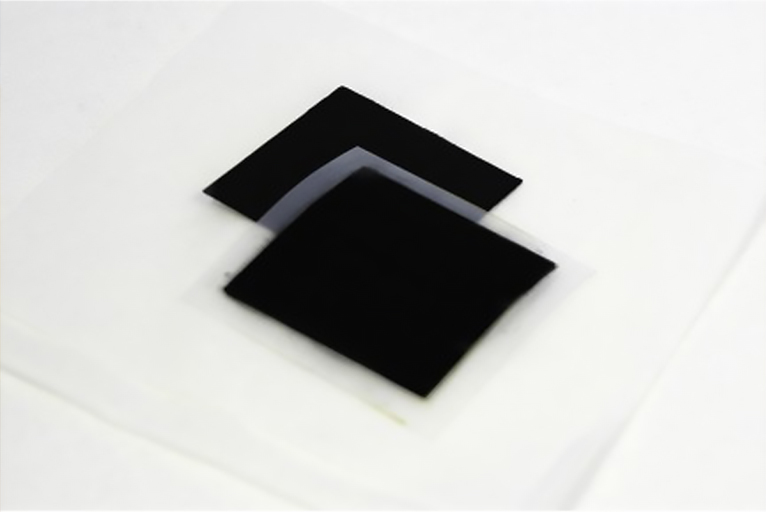

The process of preparing membrane electrode by ultrasonic spraying is as follows: first, the proton exchange membrane adsorbed on the spraying base of ultrasonic spraying equipment is laid, and the spraying base is heated to 100~200℃. Firstly, the catalyst slurry was vibrated in the ultrasonic dispersing liquid storage barrel, and then combined with the ultrasonic dispersing syringe to disperse evenly. It is sprayed on proton exchange membrane under ultrasonic condition. Repeat the above process and apply the different slurry until the coating is complete. Then flip the proton exchange membrane and repeat the above steps to spray the other side to get the membrane electrode.

Why use ultrasonic spray? The comparison is as follows:

▶ Kinetic energy atomization of both gas and liquid fluids

▶ Spray has large impact force, which will cause spatter and waste of raw materials

▶ The uniformity of atomized particles is poor

▶ Easy to block the sprinkler head

▶ Cannot accurately control the spray flow rate, and cannot spray continuously at a lower flow rate

*Traditional two fluid spraying

★ Use high frequency ultrasonic vibration to atomize liquid

★ Spray impact is very small, will not cause splashing and waste of raw materials

★ Atomized particle uniformity > 95%

★ It is not easy to block the nozzle

★ High precision control coating thickness

*YMUS Ultrasonic spraying