google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Drug eluting stent coating process -- Interventional stent spraying -- YMUS ultrasonic spraying

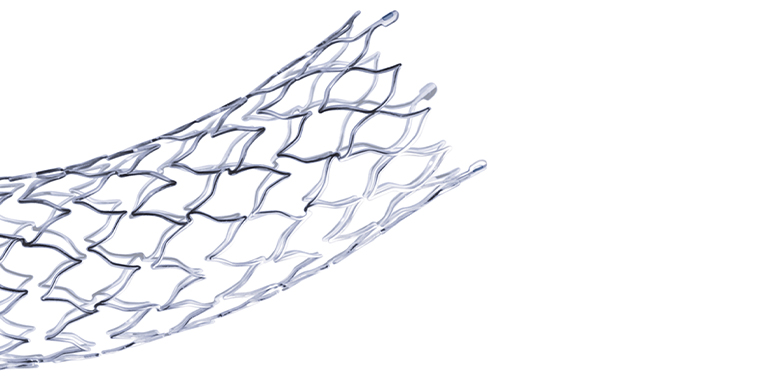

The coating process of drug-eluting stents plays a key role in the success of stents. With the development of technology research, the development and application of scaffold coating technology has brought more hope.

Coating requirements for drug-eluting stents:

1. The coating is stable, does not change its morphology and physical and chemical properties, and will not break and fall off during the process of stent implantation and release;

2. Do not change the mechanical properties of the support of the bracket itself;

3. The release of coating drugs meets the requirements;

Stent pretreatment:

The pretreatment of the scaffold is to clean the surface of the metal scaffold so as to facilitate the uploading of the latter step, namely the active drug (or the controlled release carrier). The pretreatment of the scaffold cannot change the physical and chemical properties of the surface of the metal scaffold itself.

Upload of active drug (or with controlled release carrier) :

The upload of the active drug (or with the controlled release carrier) is the key to the success of the entire coating process, but the method of coating the drug on the surface of the scaffold, in which the physical method coating process is spraying.

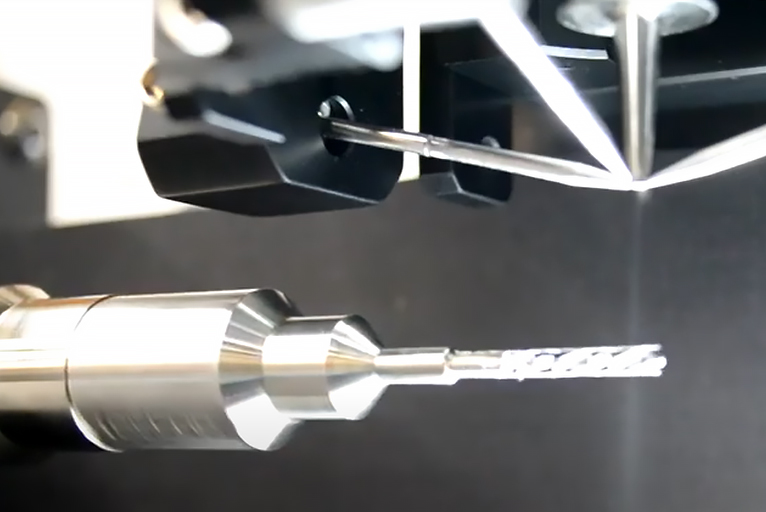

Ultrasonic spraying

The process is mainly to prepare solution of active drug and controlled release carrier (or single active drug), and then evenly coat the solution on the surface of the stent through the special spraying equipment of ultrasonic atomizing nozzle. After drying and curing and other post-processing steps, the drug-coated stent is made. The YMUS-X small-area spraying nozzle can spray different solutions on the stent in turn. Forming micron level multi-layer coating scaffold. Spraying process has certain requirements for spraying equipment, so that the position of nozzle and support, spraying speed and duration can be more accurately controlled. But compared with soaking process, spraying process has better control over coating thickness and loading capacity.

Ultrasonic spraying equipment drug eluting stent spraying

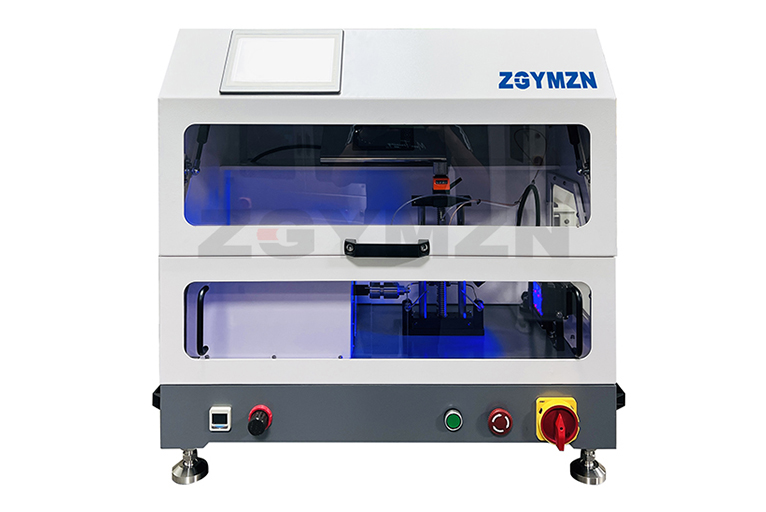

YMUS-ZJ100 Drug eluting stent spraying equipment

YMUS-ZJ100

Characteristics of ultrasonic spraying

1, reduce solution waste: compared with traditional penetration to save drugs;

2, surface atomization uniformity: compared with the traditional high pressure spray uniformity;

3, precise control of coating thickness load, high consistency;

4, no adhesion pinhole orange peel and other defects;