google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Introduction of ultrasonic spraying machine -- Ultrasonic nozzle -- YMUS ultrasonic spraying

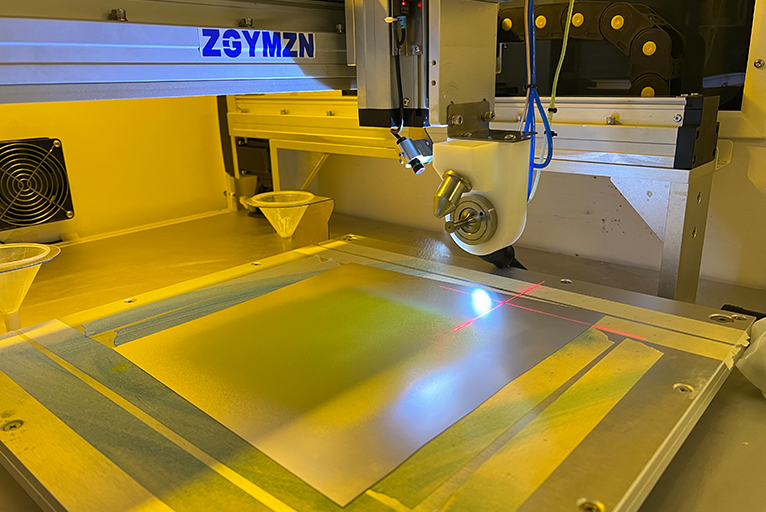

YMUS-ZS400 ultrasonic spraying equipment is a pilot test equipment designed by Shanghai Yangmi Intelligent Technology Co., Ltd. for the production of new energy, semiconductor microelectronics, nanomaterials and glass coating. The effective spraying area is 400x400mm, and the equipment can be equipped with ultrasonic nozzle and vacuum adsorption heating platform. The equipment can be heated up to 700℃, equipped with servo drive motion module, effectively ensure the spraying accuracy.

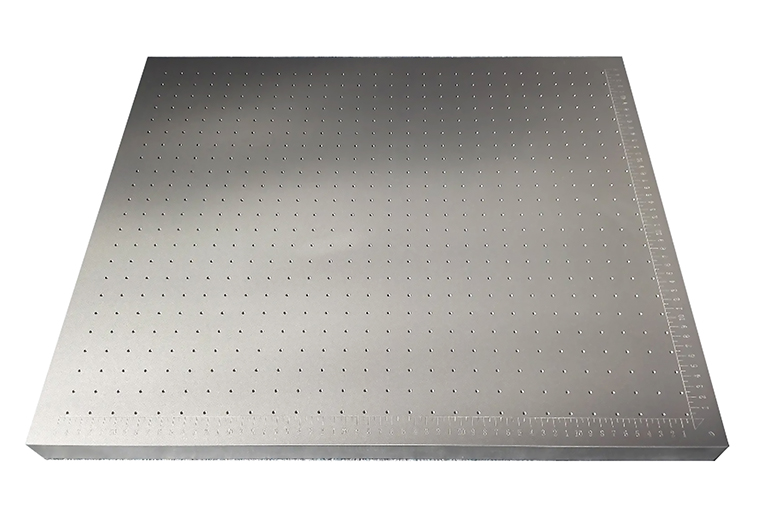

High precision vacuum adsorption heating platform:

The maximum temperature of the vacuum adsorption heating platform is 700℃, the temperature control precision is 0.1℃, the automatic constant temperature system, the panel temperature difference is ±3℃. Material with high temperature resistant carbon fiber, not easy to deformation. The default configuration is 400x400mm extensible and customized.

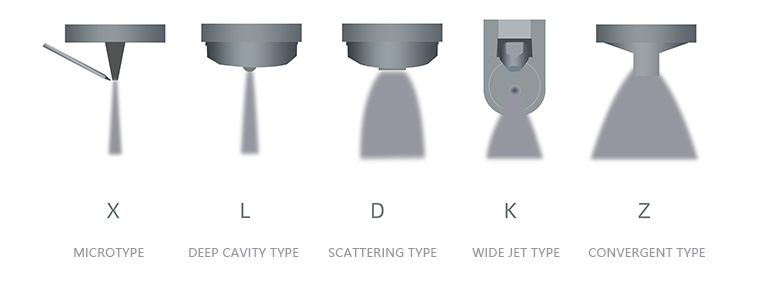

Advantages of ultrasonic nozzle:

YMUS Ultrasonic Nozzle provides precise spray distribution and different spray shapes.

During ultrasonic atomization, the size of the droplets is determined by the vibration frequency of the nozzle, the surface tension and density of the liquid, among which the frequency is the determining factor. The higher the frequency, the smaller the diameter of the median size of the droplets.

Generally speaking, the size distribution of fog droplets generated by ultrasonic sprinkler follows a normal distribution curve. The chart below shows the cumulative size distribution of fog droplets with water as the medium at different frequencies. There are several parameters that can describe the mean and median of a particular distribution of droplets. The median diameter of the number of droplets refers to 50% of the size of the droplets, that is, half of the diameter of the number of droplets is greater than this value and the other half is less than this value.

Ultrasonic equipment characteristics:

Ultrasonic atomizing spraying technology is a new ultra-thin film coating preparation technology. Compared with the traditional air spraying, two-fluid spraying, vacuum coating, CVD, spin coating, dip coating, roll coating and other surface coating technology, ultrasonic spraying technology has its unique advantages and characteristics. Shanghai Yangmi's ultrasonic precision spraying system provides key manufacturing solutions for thin-film solar cells, fuel cells and photovoltaic solar panels. Such as proton exchange membrane fuel cell CCM film electrode preparation, perovskite solar cell preparation, transparent conductive film preparation, AR anti-reflection and anti-reflection film preparation and so on. Shanghai Yangmi provides all-round ultrasonic spraying solutions from research and development, pilot test to mass production.

Application field:

◆ New energy: fuel cell, film electrode, film solar cell, exchange film, etc.

◆ Medical treatment: balloon catheter, blood vessel injector, stent, biosensor, microfluidic chip, etc.

◆ Microelectronics semiconductor electronics: flux, photoresist coating, conductive coating, hydrophilic coating, etc.

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresist film, transparent conduction, etc.;

◆ Nanotechnology: carbon nanotubes, polymer fibers, nano films, etc.;

Our continuous innovation makes our ultrasonic application and surface treatment application from research and development to mass production, in the global industry of the most complex and diversified food, new energy, medical, semiconductor, textile, automotive, shipbuilding, aerospace, petrochemical, 3C electronics industry and other complete application solutions, we continue to ultrasonic application and surface treatment application technology innovation, Provide leading technology, excellent performance of intelligent equipment.