google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Plasma treatment to improve bonding -- plasma surface treatment -- Shanghai Yangmi plasma treatment

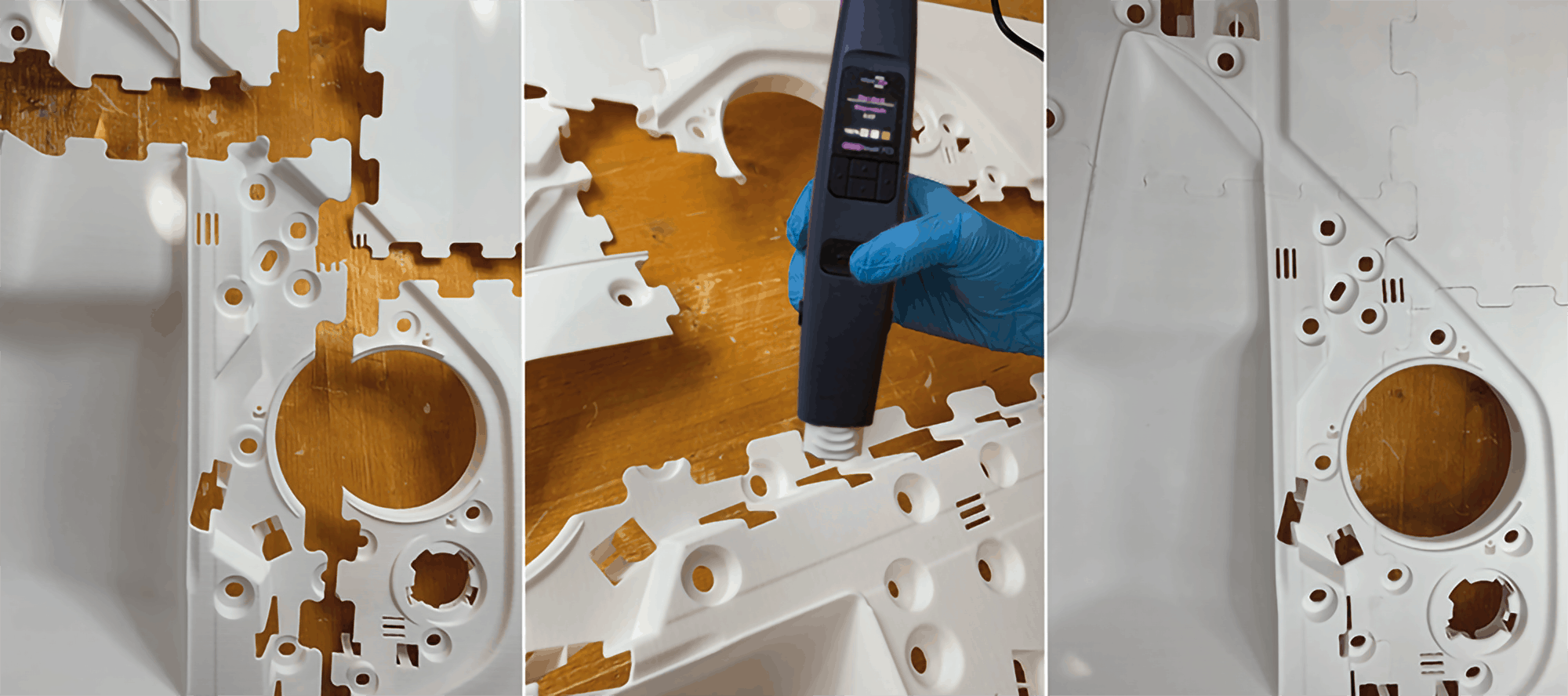

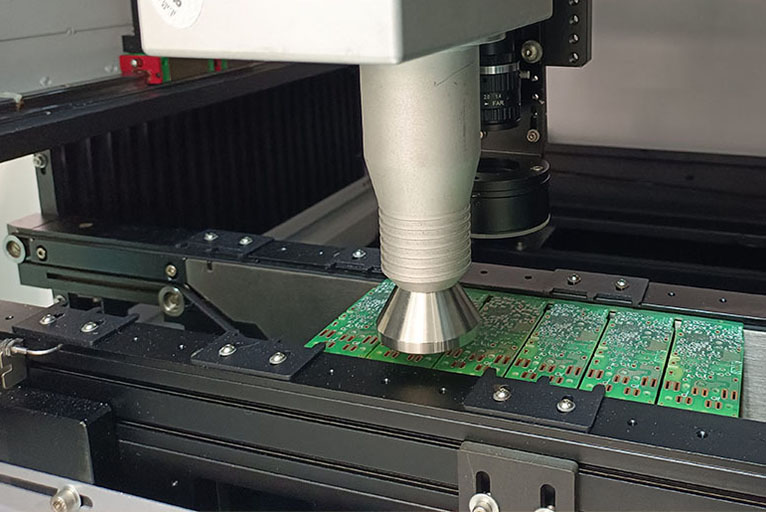

When the surface is treated with plasma prior to bonding, the resulting bonding will show a strong bonding improvement. Plasmas can be used in a variety of materials: metals, glass, ceramics, and even natural materials, such as wood and textiles, respond very well to plasma functionalization.

Plasma treatment to improve bonding

Surface functionalization by plasma treatment depends on a combination of effects: hyperfine surface cleaning of organic contaminants, modification of surface morphology, modification of surface crystal structure, and deposition of functional chemical groups. The metal can be removed from the hard oxide and reduced to a pure metal surface.

The atmospheric pressure in our plasma system is generated by air or typical industrial gases such as hydrogen, nitrogen, or oxygen. For the customer, this means a huge improvement in cost effectiveness, process safety and environmental compatibility, as expensive vacuum equipment or wet chemistry is no longer really necessary. The fast processing speed makes our system suitable for a variety of industrial applications.

Advantages of plasma treatment:

Plasma cleaning, strengthening, and chemically functionalized surfaces improve all of these effects needed for bonding

Ultra-fine cleaning, no residue

Mild, non-destructive finish

Wet free chemistry

Air or a cheap non-toxic working gas

Environmental protection

Quick processing

Easy to integrate into existing production lines

Plasma processing