google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Large-area helium-iron solar cells - thin film preparation - ultrasonic spraying

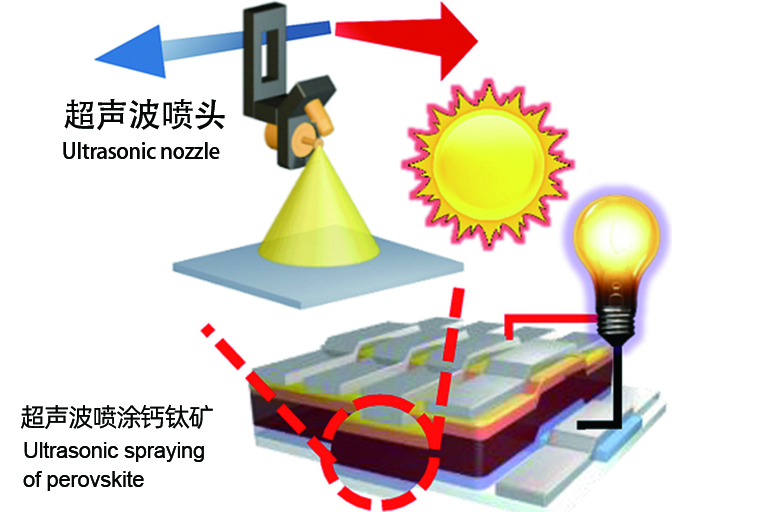

Pathways to large-area perovskite solar cells

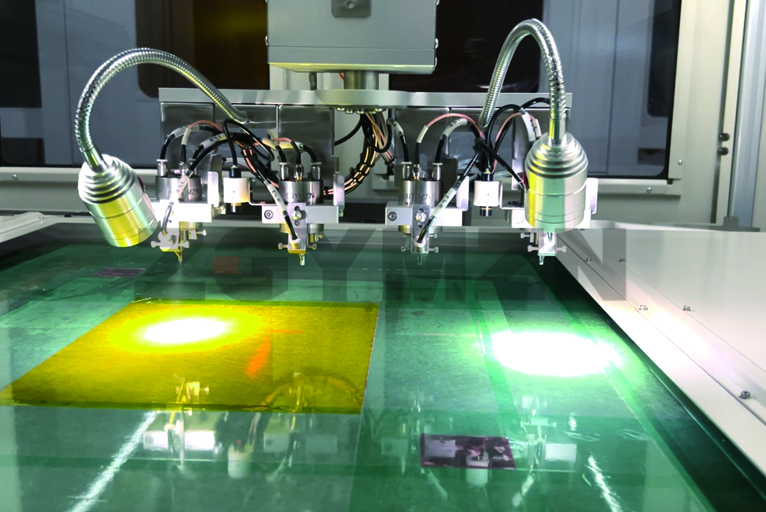

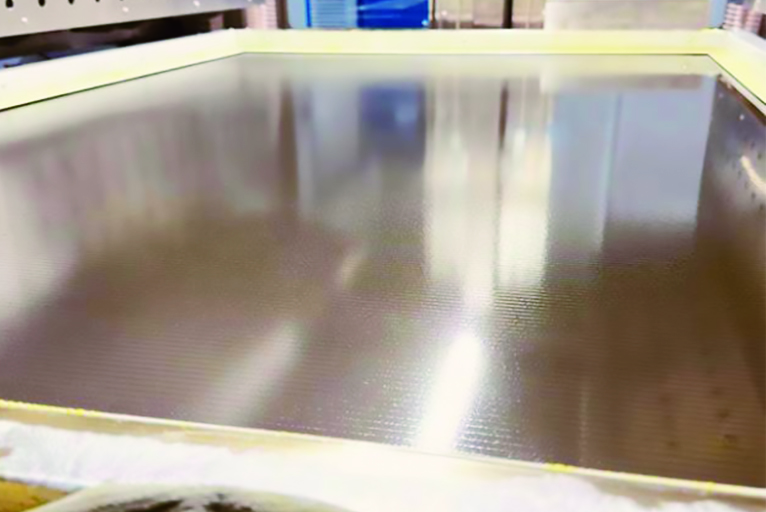

The traditional spin coating method has been proven to produce uniform, void-free, high-quality perovskite films, but it is not suitable for preparing large-area perovskite films. Ultrasonic spraying technology is a commonly used method for preparing large-area perovskite films. The intermediate phase problem generated during the process from precursor solution to film generation needs further in-depth study. The reversibility and stability of the intermediate phase directly affect the film-forming properties of perovskite films. In the process of preparing perovskite from precursor solution to film, we should not only pay attention to its chemical process, but also study its physical properties involved, such as solution viscosity, substrate wettability, etc.

Effect of impurities in the perovskite precursor solution

The presence of impurities in the perovskite precursor solution will affect the performance of the perovskite film, such as the crystallinity of the film, the recombination process of carriers, and the charge diffusion length.

>Studies have shown that PbI₂ (98.0%) exhibits lower crystallinity than PbI₂ (99.999%), which reduces the carrier lifetime and diffusion length of the perovskite film and thus reduces the photoelectric performance of the device.

>Studies have shown that adding hypophosphorous acid (HPA) to HI can act as a stabilizer, reducing the oxidized I₂ to I¯, thereby improving the photoelectric performance of the perovskite film.

Ultrasonic spraying is usually formulated with lower concentration solutions to produce perovskite films of desired thickness. If the solvent evaporates too quickly, the droplets of the solution will not have enough time to spread out and combine into a uniform film. Conversely, if the drying process continues for a longer time, the wet film will shrink into a film with poor coverage. Therefore, the control of spraying perovskite films is a big challenge, and the PCE of spraying devices is relatively low. Optimizing spraying speed, substrate temperature, nozzle-to-substrate distance, wet film annealing temperature and time, as well as ink concentration, viscosity, and solvent flux can improve film quality and thickness.