google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

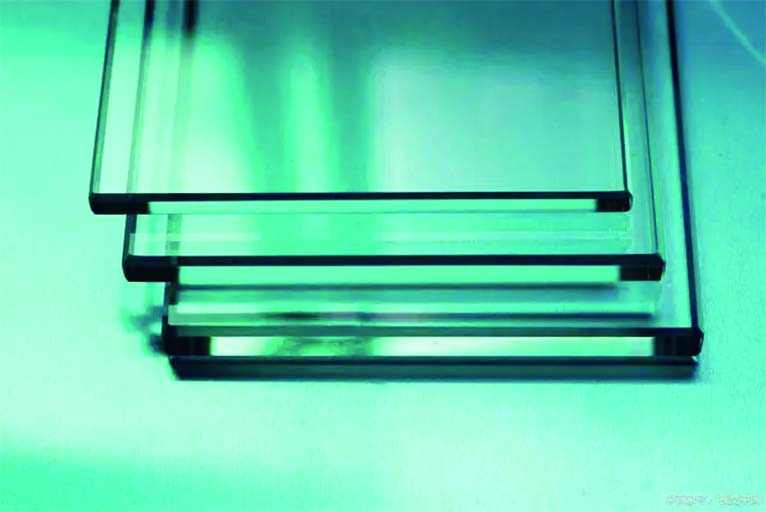

ITO conductive glass - precision coating preparation - ultrasonic spraying

With the development of technology, ITO conductive glass is still innovating and improving, bringing more possibilities to the optoelectronic field.

ITO conductive glass is a transparent conductive material composed of indium oxide and tin oxide. It has excellent transparency, conductivity, corrosion resistance, mechanical strength and thermal stability. According to the characteristics and structure of the conductive film, ITO conductive glass can be divided into different types such as single-sided conductive glass, double-sided conductive glass, flexible conductive glass and customized conductive glass. These characteristics and classifications make ITO conductive glass widely used in fields such as flat panel displays, solar cells, touch screens and liquid crystal displays, and provide efficient conductive functions for optoelectronic devices.

The production process of ITO conductive film glass can be divided into two categories: touch screen and LCD. In addition to adding TiO 2, Nb 2O 5 and other multi-level coating processes to AR glass, the ITO conductive film glass for LCD also needs to change the control standards of relevant process parameters. At the same time, due to different product specifications, especially the different requirements for the core technical indicators of transmittance and film conductivity, the requirements for the conductive glass film structure, coating process and coating technology are also different.

● Single-sided conductive glass

It means that the ITO conductive film is only covered on one side of the glass. This conductive glass is widely used in touch screen devices such as smartphones and tablets, as well as optoelectronic devices such as liquid crystal displays.

● Double-sided conductive glass

It means that the ITO conductive film is covered on both sides of the glass. This conductive glass is often used in applications such as flat panel displays and solar cells that require bidirectional conductive functions.

● Flexible conductive glass

It is a conductive material with bendability and stretchability. It uses a special substrate material that allows the ITO conductive film to maintain its conductive properties when bent. This flexible conductive glass is widely used in flexible displays, wearable devices and other fields that require curved displays and flexible properties.

● Customized conductive glass

In addition to the above common classifications, ITO conductive glass can also be customized according to different application requirements. For example, in the field of solar cells, higher light transmittance and conductivity can be achieved by adjusting the thickness and resistivity of the ITO conductive film.

Ultrasonic spraying of ITO solution can produce ITO thin films with small particles, uniform particles, transparency, density, hardness and excellent photoelectric properties. The development of related fields for such thin films will have broad application prospects.

The advantages of ultrasonic spraying of ITO solution to prepare optical thin films are as follows:

(1) Good uniformity: Using the powerful energy oscillation force of ultrasound to mix ITO powder and solvent can effectively prevent powder agglomeration to prepare a uniform suspension, so that ITO condenses on the surface of the substrate with high uniformity.

(2) High density: The density of suspended particles and substrate in the ultrasonically treated solution is high, the film layer is relatively dense, and a high-quality film layer with good optical properties can be obtained.

(3) Low cost: The process of ultrasonic spraying of ITO solution to prepare optical thin films is simple, easy to operate, low cost, high efficiency and industrial application prospects.

(4) Good transparency: Since ITO optical thin films have high transparency, they can be used in various optical instruments, displays and solar cells, and can achieve good optical properties.