google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Proton exchange membrane industry research——Preparation process——Shanghai Central meter ultrasonic spraying

Proton exchange membrane has special proton transfer function, and has been widely used in hydrogen energy, liquid flow battery and other fields, among which perfluorinated proton membrane is the most important one. Its raw material is perfluorinated sulfonic acid resin, which is made of PSVE monomer and tetrafluoroethylene copolymerization. The preparation of PSVE monomer, the acquisition of tetrafluoroethylene, the polymerization of resin and the final film forming process determine the production difficulty of proton film.

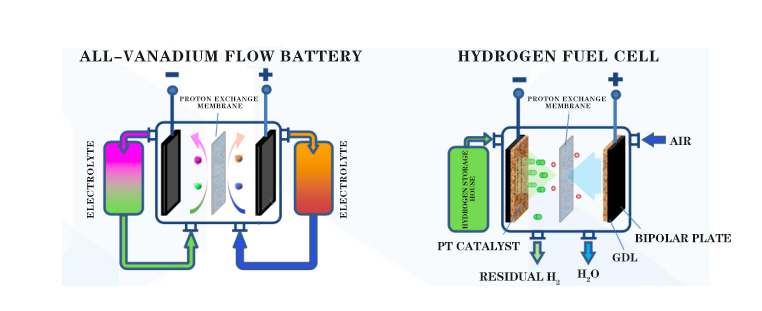

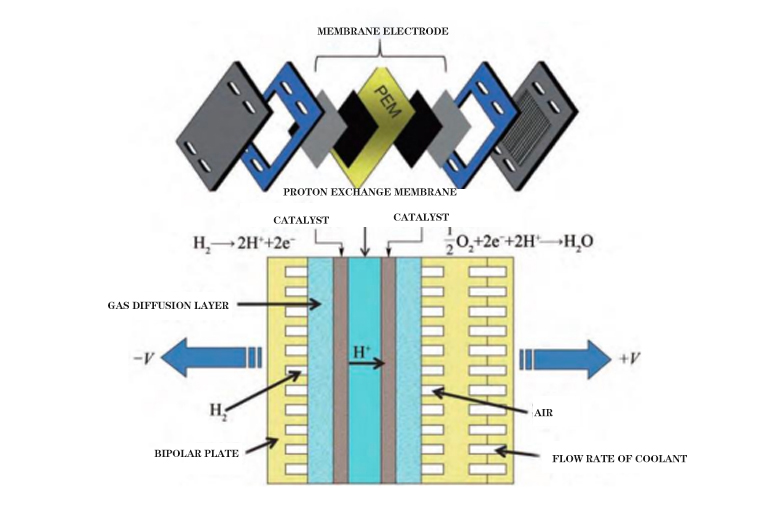

I. The role of proton exchange membrane

Proton exchange membrane (PEM) is the end product of organic fluorine chemical industry, widely used in the fields of chlor-alkali, fuel cells, hydroelectricity hydrogen production and energy storage batteries, mainly because of its unique proton transfer function, so that the electrode reaction is smooth. In the case of the fuel cell proton exchange membrane, hydrogen gas passes through the gas diffusion layer and becomes protons under the action of the anode catalyst. The protons are specially transferred to the cathode on the PEM membrane and react with oxygen ions to form water molecules. At certain temperatures and humidity, PEM membranes transfer only protons, and gas molecules cannot pass through. Electrons travel through an external circuit to the fuel cell cathode to form a current. The main mechanism of proton exchange membrane is not through exchange, but through selective transmission.

Ii. Application scenarios of proton exchange membrane

Taking hydrogen fuel cells as an example, compared with conventional fuel vehicles, the vehicle can also be divided into four modules: power system, chassis, automotive electronics and body. Fuel cell vehicle has added fuel cell system and on-board hydrogenation system, among which fuel cell system is its core structure. As the core unit of the fuel cell system, the fuel cell reactor can convert the chemical energy of hydrogen into electric energy and drive the motor together with the battery to provide power for the vehicle.

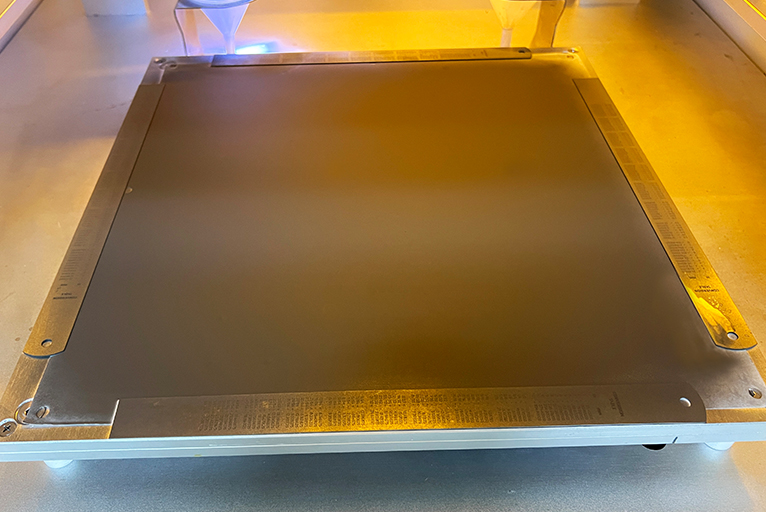

The general process of ultrasonic spraying preparation is as follows:

First, the catalyst slurry is dispersed and stirred in the ultrasonic dispersion liquid storage barrel to avoid agglomeration and precipitation of the dispersion liquid in the process, and the ultrasonic spraying equipment is coated on the substrate (GDL or PEM). In addition, compared with traditional spraying methods, the Pt loading of MEA prepared by ultrasonic spraying is the lowest.

Ultrasonic spraying has the following advantages:

(1) High precision of coating thickness control: coatings ranging from 20 nm to tens of microns can be prepared to accurately control the coating thickness;

(2) The nozzle is not easy to clog, efficient and uniform film spraying;

(3) Simple operation, automatic process, suitable for mass production of MEA;

YMUS Ultrasonic spraying is a fully automatic, programmable independent system with coordinated XYZ motion control for multi-functional medium to high volume or pilot scale film coating production.

YMUS-ZX400 ultrasonic spraying system

Proton exchange membrane

Shanghai Yangmi ultrasonic spraying system coating proton exchange membrane industry application, ultrasonic application and surface treatment application from research and development to mass production, one-stop nano coating quality process and solution, ultrasonic spraying equipment technology application.