google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Silicon carbide seed crystal adhesion characteristics and equipment -- graphite adhesive layer -- YMUS ultrasonic spraying

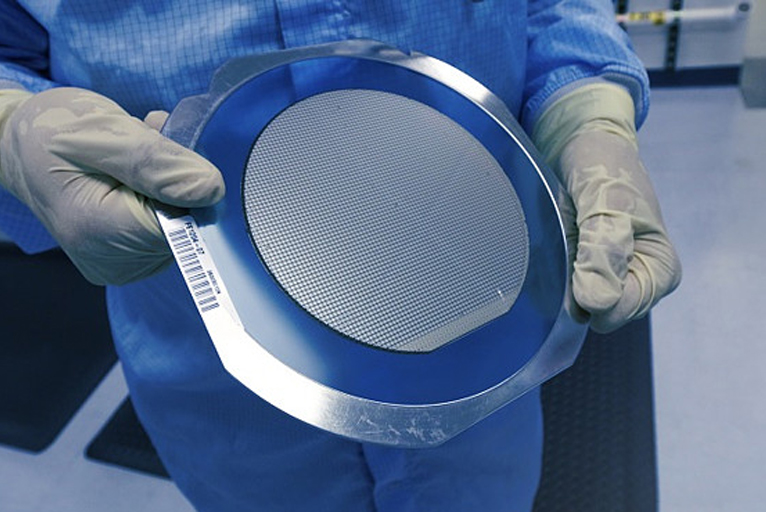

Compared with silicon, silicon carbide has a larger band gap and better dielectric breakdown performance, heat resistance, radiation resistance, etc., so it is suitable for electronic device materials such as portable and high output semiconductors, and because of its excellent optical properties, it is also used as optical device materials. Compared with silicon carbide polycrystal, silicon carbide single crystal has the advantages of uniformity in wafer and other devices. Especially for new energy vehicles in the power exchanger, battery charger, motor driver is the future market focus.

Function of seed crystal binder:

1. When seed crystal and seed crystal cap combine to grow single crystal, the formation of microcracks caused by bonding failure is inhibited, and these defects will form macroscopic defects;

2. Prevent the continuation of microtubules;

3. prevent backside sublimation;

4. a certain bond strength;

5. Form a protective layer;

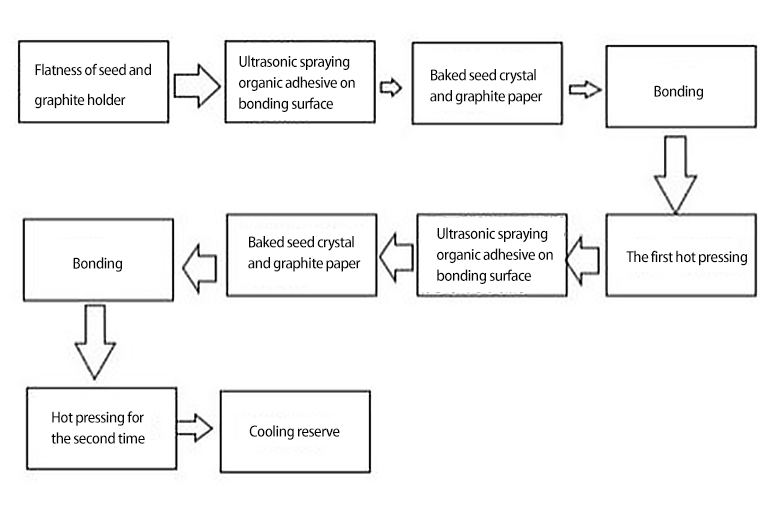

The usual process structure is as follows:

1. seed crystal seed

2. graphite paper buffer layer

3. Protective layer

4. Grow crystals

The back of the seed crystal forms a protective layer, which is bonded by an adhesive and a buffer layer (graphite paper), which is bonded by the adhesive and the seed crystal cap.

How does the combination of spraying adhesive on seed crystal and graphite paper reduce the failure rate?

YMUS ultrasonic precision spraying equipment ensures uniform distribution of adhesive thickness between seed crystal and seed crystal holder, avoiding cracking of seed crystal due to uneven mechanical stress and thermal stress.

1. Improving the bonding quality of seed crystals is the primary premise for ensuring the growth of high-quality silicon carbide crystals. The bonding quality of seed crystals is evaluated and optimized from the aspects of the flatness of silicon carbide seed crystals and graphite holder as well as the firmness, uniformity and compactness of the bonding between them.

2. Uniformity requires uniform thickness of adhesive layer, and uniform thickness of adhesive layer is a prerequisite for density. YMUS ultrasonic spraying equipment atomization uniformity ≥95%, to ensure that the organic glue coated on the surface of seed crystals and graphite support, enhance stability.

3. The density requires that the bubbles in the rubber layer be cleaned out, or the bubbles are evenly distributed in the rubber layer, which is not enough to cause the difference in radial temperature on the back of seed crystal.

YMUS-ZS400 Ultrasonic spraying equipment