google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Conductive coating, electrode material -- polymer material -- YMUS Ultrasonic spraying

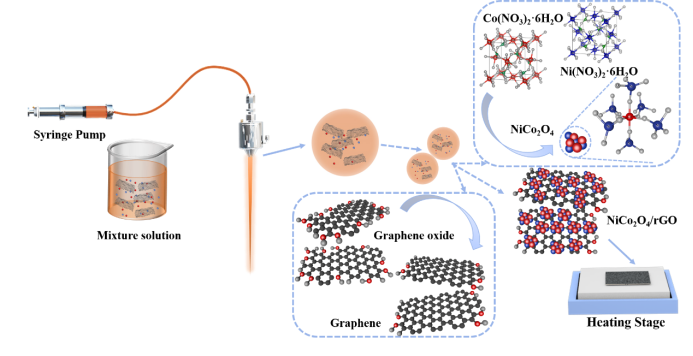

Long life and low cost electrode materials are very important for the practical application of supercapacitors. NiCo2O4/ Reduced graphene oxide (NiCo2O4/rGO) composites with large area of hierarchical porous structure were prepared on the surface of nickel foam by ultrasonic spraying method. The NicO2O4 / RGo composites were directly used as bonding-free electrodes for KOH electrolyte supercapacitors.

The layered NiCo2O4/rGO composite electrode with hierarchical porous structure was prepared by YMUS ultrasonic spraying technique. NiCo2O4 nanoparticles grown in situ on rGO nanosheets during spraying not only improve the specific capacitance of the electrode through Faraday oxidation-reduction reaction, but also act as spacers to prevent the stacking of graphene during electrode preparation and promote the formation of layered porous structures. Large area electrode materials can be prepared, which provides the possibility for the practical application of graphene-based composite electrode materials.

YMUS-ZM200 Ultrasonic spraying equipment

Device Features

◆ Ultrasonic spraying equipment, using ultrasonic sprinkler technology, can provide uniform and efficient film spraying;

◆ Coating thickness control precision: can prepare tens of nanometers to tens of microns of the coating, accurate control of coating thickness;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times traditional two-fluid spraying;

◆ XYZ three axis servo motion system;

◆ Full color touch screen control and friendly man-machine interaction interface;

◆ High precision laboratory injection pump;

◆ Wide range of liquid flow: 0.001ml/min - 50ml/min; (depending on the solvent and nozzle model)

◆ Imported high precision precision pressure reducing valve and liquid valve, to achieve high speed and stable gas and liquid coordination;

◆ Laser alignment: to assist users to locate the nozzle position easily and quickly;

◆ Built-in exhaust gas exhaust system, does not block nozzle technology, reduce maintenance costs;

◆ Micrometer micro hole vacuum suction heating, suitable for battery diaphragm and other flexible substrates; (extensible)

◆ Up to 500°C hot table, suitable for film preparation by spray pyrolysis; (extensible)