google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The main material of optical film ITO - conductive film - YMUS ultrasonic spraying

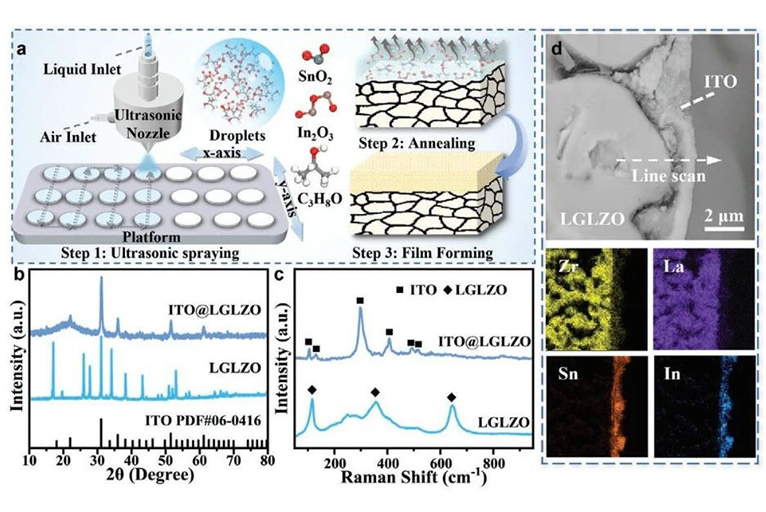

All-solid-state lithium batteries (ASSLBs) have the advantages of high energy density and safety, and are expected to become the next generation of energy storage systems. However, the successful commercialization of garnet based ASSLIB has been hampered by poor contact between the solid electrolyte (Li6.25Ga0.25La3Zr2O12, LGLZO) and the lithium anode, as well as low critical current density (CCD). The indium tin oxide (ITO) layer was prepared on LGLZO by ultrasonic spraying technology. ITO reacted with molten lithium to form a composite sandwich composed of Li13In3, Li2O and LiInSn.

YMUS ultrasonic spraying dispersed ITO uniformly on the surface of LGLZO. The ultrasonic nozzle moved horizontally and vertically during the spraying process. A dense grid is outlined in the spray path to ensure uniform and precise coating preparation.

ITO Application field

The main application areas of optical films prepared by ultrasonic spraying ITO solution include the following aspects:

(1) optoelectronics industry: ITO materials have good electrical conductivity and optical transparency, so they can be used for etching templates, optical displays, solar cells, photoelectric control devices and lighting devices.

(2) Biomedical field: Using ITO glass as the surface carrier of biological materials, ideal biosensitive films can be prepared for biological detection.

(3) Sensor industry: Using the electrical properties of ITO materials, various sensors can be prepared, especially optical sensors, gas sensors, water quality sensors, etc.

The advantages of ultrasonic spraying ITO solution to prepare optical films are as follows:

(1) Good uniformity: The use of ultrasonic powerful energy oscillation force to mix ITO powder and solvent, can effectively prevent powder agglomeration, to prepare a uniform suspension, so that ITO condensation on the substrate surface of high uniformity.

(2) High density: the suspended particles and the base page in the ultrasonic treated solution have high density, and the film layer is relatively dense, and a high-quality film layer with good optical properties can be obtained.

(3) Low cost: The process of ultrasonic spraying ITO solution to prepare optical film is simple, easy to operate, the cost is low, and has high efficiency and industrial application prospects.

(4) Good transparency: Due to the high transparency of ITO optical film, it can be used in various optical instruments and equipment, displays and solar cells and other fields, and can achieve better optical performance.

ITO films with small particles, uniform particles, transparent, dense, hard and excellent photoelectric properties can be prepared by ultrasonic spraying ITO solution. The development of such films will have broad application prospects in related fields.