google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

In the early days of the solar cell industry, traditional spraying technology had many limitations in key links such as the preparation of battery films, such as uneven coating thickness and serious material waste, which limited the conversion efficiency and production benefits of solar cells. With the continuous advancement of technology, ultrasonic spraying equipment came into being. The application of ultrasonic spraying technology in the field of solar cells has gradually emerged as scientific researchers have deepened their exploration of its principles and advantages, and the demand for improving the performance of solar cells has become increasingly urgent. In recent years, with the pursuit of high efficiency and low cost of solar cells, Shanghai Yangmi ultrasonic spraying equipment has continued to innovate in research and development and manufacturing processes. Its application in solar cell production lines has become more and more popular, becoming an important force in promoting the development of the solar cell industry.

Application fields

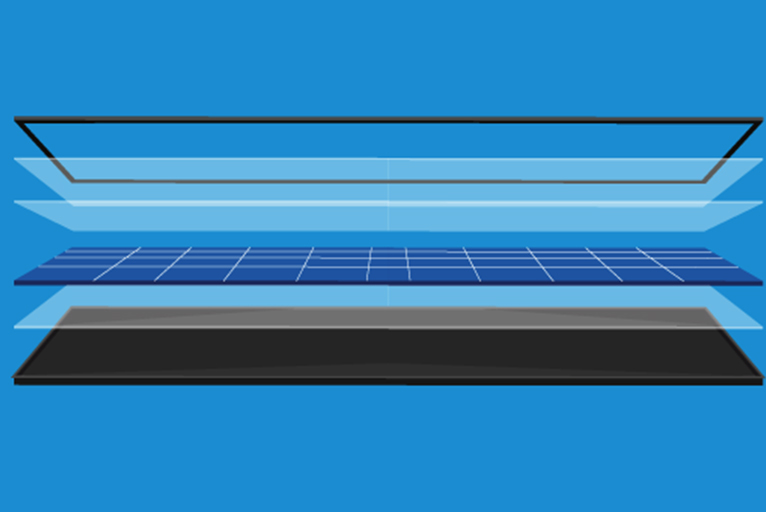

1. Preparation of photovoltaic cell electrodes: In photovoltaic cells, the quality of electrodes has a significant impact on cell performance. Ultrasonic spraying equipment can accurately spray conductive slurry on the cell substrate to form a uniform, dense and precisely controlled electrode layer, effectively reducing electrode resistance and improving the charge collection efficiency of the cell, thereby improving the overall conversion efficiency of the photovoltaic cell.

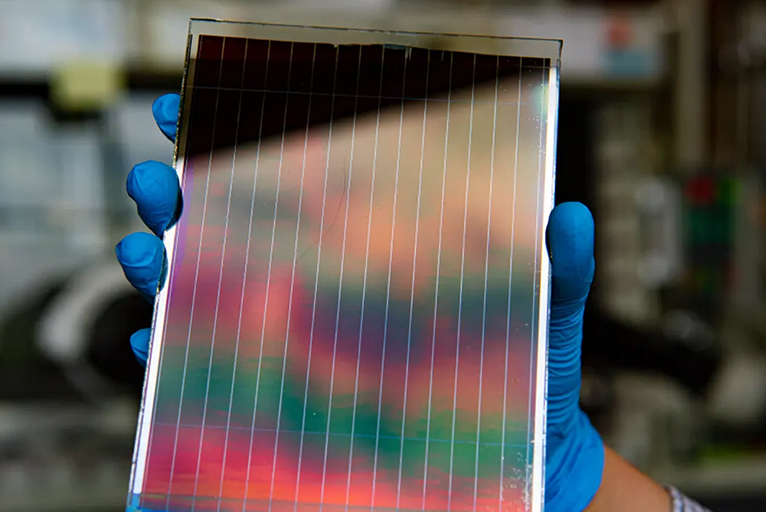

2. Preparation of perovskite solar cells: As a new type of high-efficiency solar cell, perovskite solar cells have extremely high requirements for film quality. Ultrasonic spraying can achieve uniform atomization and precise spraying of perovskite precursor solution, prepare high-quality and uniform perovskite films, help improve the stability and photoelectric conversion efficiency of the cell, and is one of the most concerned technologies in the current perovskite solar cell preparation process.

3. Anti-reflection coating for solar cells: In order to reduce the light reflection loss on the surface of solar cells, an anti-reflection coating needs to be applied. Ultrasonic spraying equipment can evenly spray anti-reflection materials on the cell surface to form a coating with ideal optical thickness and microstructure, maximize the light transmittance, increase the cell's absorption of light energy, and thus improve the cell performance.

Advantages and characteristics of ultrasonic spraying technology

1. High-precision coating control: Through the high-frequency vibration of ultrasound, the coating is atomized into extremely small and uniform particles, which can accurately control the thickness of the coating, and the deviation can be controlled within a very small range, meeting the high-precision requirements of solar cells for film thickness and ensuring the consistency and stability of battery performance.

2. High material utilization rate: Compared with traditional spraying methods, the droplets of ultrasonic spraying are uniform and directional, and can be accurately sprayed in the target area, greatly reducing the splash and waste of materials, improving material utilization, and reducing production costs. It is especially suitable for expensive solar cell materials.

3. Good film quality: The formed coating is uniform and dense, and the microstructure is more ideal, which helps to improve the various performance indicators of solar cells, such as conversion efficiency and stability. At the same time, the uniform coating can also reduce the performance degradation of the battery during long-term use and extend the battery life.

4. Strong flexibility and adaptability: It can adapt to many different types of coatings and materials, whether it is solution, slurry or nanomaterials, etc., and can achieve efficient spraying. And it can be sprayed on solar cell substrates of different shapes and sizes to meet diverse production needs.