google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Used for selective ultrasonic flux system -- ultrasonic atomization -- YMUS ultrasonic spraying

YMUS Selective Flux spraying system will spray all flux without blocking nozzle, higher accuracy, higher atomization volume, reduce excessive spraying.

YMUS has extensive experience in ultrasonic spray technology, and the non-clogging nature of our ultrasonic nozzles gives us a significant advantage over other flux methods in precision selective flux for SMT boards and components, as well as through-holes and flux for stand-alone and inline systems. We have a full range of spray systems to meet the needs of PCB manufacturers.

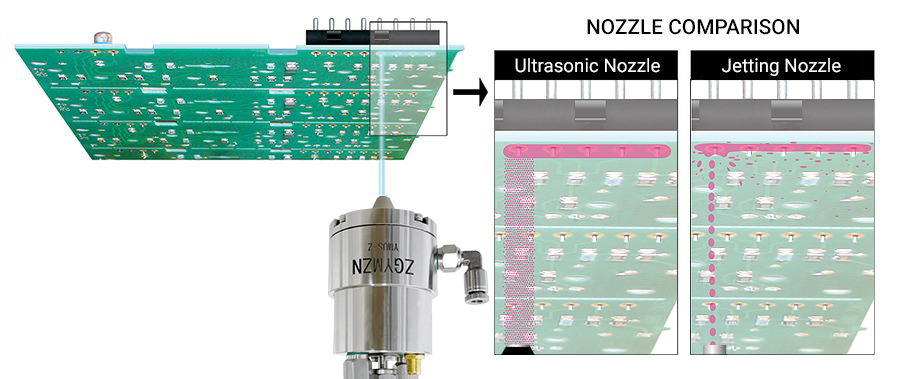

Note:Comparison of nozzle

Selective soldering flux systems include:

● Adjustable ultrasonic nozzle

● Touch screen control

● Air and flow regulation

● Ultrasonic dispersion liquid storage tank

For selective flux applications, YMUS Ultrasonic Selective Flux System offers the highest degree of precision and fine line control in the selective flux industry. Controlled spray speed does not harm or disturb components while giving maximum top fill in selective flux applications.

Note:YMUS-CS600 Ultrasonic spraying system

Equipment characteristics

◆ With material transfer machine, automatic transmission of substrate;

◆ Can be equipped with multiple nozzle array, greatly improve the production speed;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times the traditional two fluid spraying;

◆ Equipped with multiple nozzles to work in parallel; (Customized according to the width of production line)

◆ A variety of high precision constant current liquid supply technology, according to different production capacity to achieve continuous steady liquid supply;

◆ Imported high-precision pressure-reducing valve and liquid valve, to achieve high-speed and stable gas-liquid coordination;

◆ Built-in exhaust gas discharge system, nozzle, liquid pipeline self-cleaning system;

◆ Non-blocking sprinkler technology, low maintenance cost;

◆ Ultrasonic dispersion liquid storage barrel, ultrasonic dispersion syringe, avoid solid precipitation in the spraying process; (extensible)

◆ Liquid level alarm system;