google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of lubricating coating by ultrasonic spraying -- Hydrophilic coating -- YMUS ultrasonic spraying

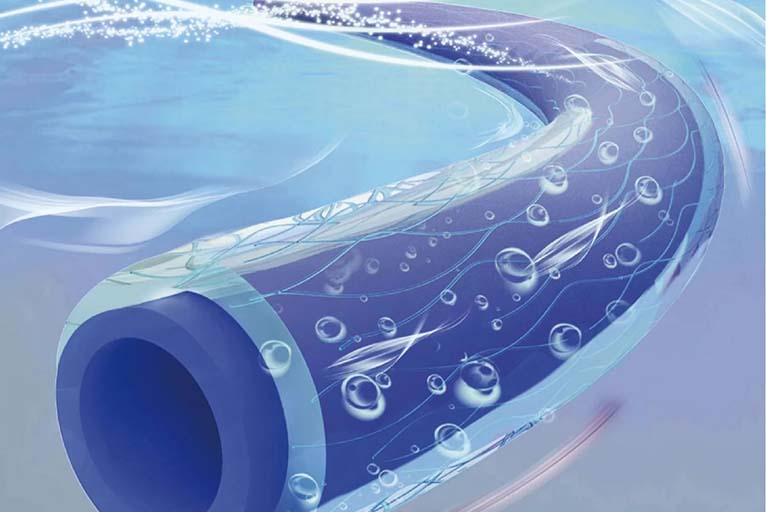

To reduce friction between instruments and vessels, lubricating coatings have been widely used on the surface of vascular intervention instruments such as intravascular catheters, guide wires and delivery systems. The application of lubricating coating in vascular interventional instruments can improve the biocompatibility of the surface of interventional instruments, reduce the damage to the vascular wall, reduce the interference of the intervention process on the blood layer flow, and make the interventional instruments better through the tortuosity of the vascular site and reduce the difficulty of surgery. However, in some cases, the coating may detach from the surface of the device resulting in adverse events. Hazards include residual coating fragments, local tissue reactions and thrombosis in patients, and even serious adverse events such as pulmonary, myocardial embolism, embolic stroke, tissue necrosis and death.

The interventional guide wire, catheter and delivery system usually move back and forth in blood vessels during clinical use to accurately reach the lesion site. The stability of the lubricating coating runs through the whole life cycle of the product, and is also one of the key contents of the technical review of product safety and effectiveness evaluation.

The application of hydrophilic lubrication coating on instrument surface can solve the problem of high friction resistance between instrument surface and human tissue. Through specific coating process (such as ultrasonic spraying) and curing process (such as UV curing, thermal curing), hydrophilic polymers with good biocompatibility (such as polyacrylamide, polyethylpyrrolidone) are combined to the surface of medical device products, and a polymer crosslinked network film is formed, that is, hydrophilic coating. The coating is quickly combined with water to form a hydration layer, so that the surface becomes very lubricated, greatly reducing the friction between instruments and human tissues, and greatly improving the operating convenience of doctors and patient comfort, to avoid possible friction damage, infection and other complications.

Note:Hydrophilic coating

The lubrication coating thickness of interventional guide wire, conduit and conveying system is usually about a few microns, and ultrasonic spraying process is adopted. Coating uniformity is also an important evaluation parameter to ensure the safety and effectiveness of coating. In addition to the appearance detection, the coating uniformity is also evaluated by micrometer thickness measurement, coating surface quality measurement, Congo red staining detection, scanning electron microscopy observation, etc.

YMUS-DG300 Drug Balloon Catheter spray machine, an ultrasonic spraying equipment specially used for drug coating of drug balloon catheter. It is equipped with a micro-ultrasonic nozzle or a converging ultrasonic nozzle to prepare the drug coating on the balloon catheter by ultrasonic spraying technology. It is characterized by accurate control of the dosage, uniform coating, no pinhole orange peel and other defects. Equipped with special balloon catheter fixture and rotating mechanism, it can be used for drug coating of coronary balloon, peripheral balloon and other kinds of drug balloon catheter. It is a widely used precision drug coating equipment of drug balloon at present.

Note:YMUS-DG300 Ultrasonic spraying equipment