google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

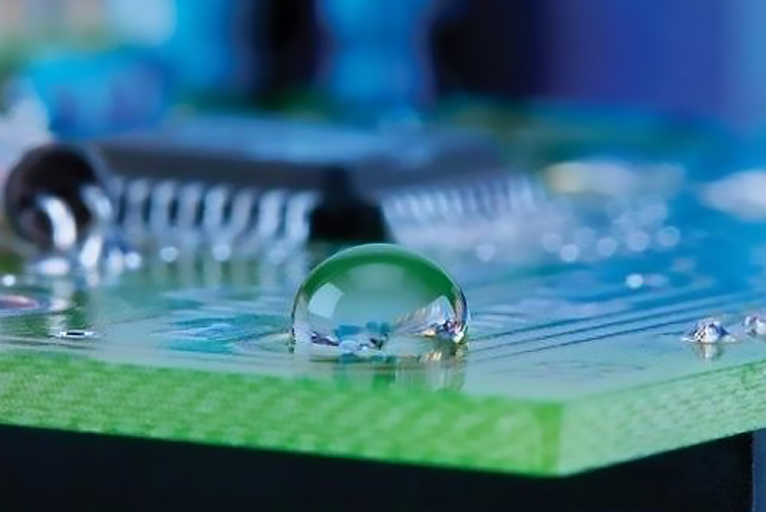

The hydrophobic and oleophobic coating -- nano coating -- YMUS ultrasonic spraying was prepared

What is the hydrophobic layer? What does that do? Is there a big difference? Hydrophobic layers are common in our lives, and you don't notice them when you touch them.

Hydrophobic and oil-repellent layer, to put it simply, is the protective layer that can separate water and oil, and the anti-pollution coating we hear everyday, namely AF (Anti Finger Print) anti-fingerprint coating, called Oleophpbic coating in English. Usually, the smooth feel of the screen of a new mobile phone is from the hydrophobic and oil-repellent coating.

AF material is a kind of fluorine-containing coating, with very low surface tension, generally known as perfluorinated polyether, the main function is to attach to the surface of the screen, increase the screen's performance of hydrophobic, oil discharge, anti-fouling and so on, widely used in mobile phones, flat panels, displays, SLR protective glass, often use electronic products with screen we can basically always access.

AF liquid material is suitable for ultrasonic spray coating. After the glass is coated and cured, AF coating is retained on the screen surface. In addition to anti-fouling, AF coating also has wear resistance and high light transmittance.

Of course, the hydrophobic layer is not only used for glass, in stainless steel can also have such a protective layer. Sprayed on the surface of various metal materials such as stainless steel plate, can form a layer of nano/micron level of ultra-thin anti-oil anti-fingerprint self-cleaning coating, can make water with ultra-high surface tension (manifested as water repellent), the formation of high water contact Angle, so that the oil will shrink into small oil droplets which are difficult to adhere to the metal surface.

YMUS ultrasonic spraying system prepares a nanoscale hydrophobic and oleophobic coating. The surface characteristics of glass lenses are tested by a water drop contact Angle tester. The hydrophobic degree of glass surface is indirectly analyzed by the water drop Angle to judge the antifouling ability of the product surface.