google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

How to improve the performance of lithium ion diaphragm? -- Film preparation -- YMUS ultrasonic spraying

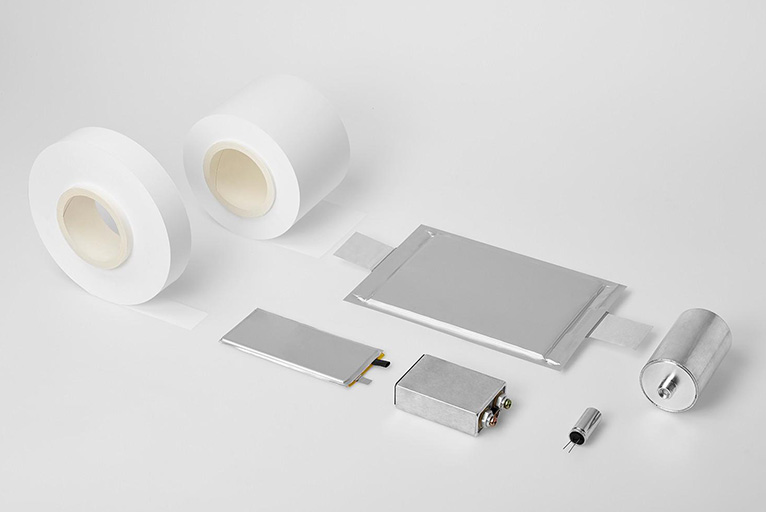

The lithium ion membrane coating process refers to a process of coating polymer materials on the surface of the carp ion battery membrane. The diaphragm is an important part of the lithium-ion battery, which is used to isolate the positive and negative electrodes to prevent short circuit and electrolyte mixing. The performance of the diaphragm has an important impact on the safety and performance of the carp ion battery.

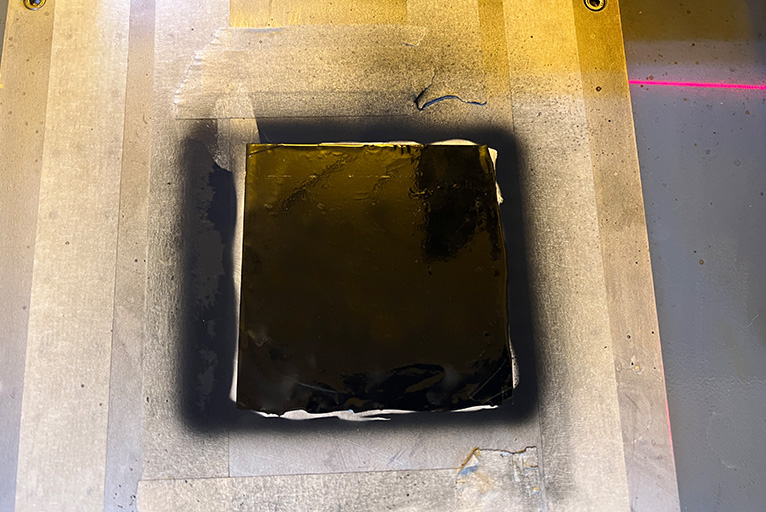

The coating process of diaphragm mainly includes two methods: wet coating method and on coating method. The wet coating method is to spray a polymer solution on the surface of the diaphragm and heat and dry the polymer to form a film. Dry coating means that the polymer is directly dry coated on the surface of the diaphragm, and then the polymer is attached to the diaphragm by heating to form a film.

The coating process of the diaphragm has an important effect on the performance of the diaphragm. Excellent coating process can improve the heat resistance, chemical resistance, conductivity and electrochemical stability of the diaphragm, so as to improve the safety and performance of potassium ion batteries. Therefore, the research and development of potassium ion membrane coating technology is very important for the development of carp ion batteries.

Advantages of ultrasonic spray preparation of lithium ion diaphragm Advantages:

● Uniformity: Ultrasonic spraying technology can achieve uniform distribution of lithium battery separator between positive and negative electrodes. Doing so ensures that the thickness and density of the isolation film is uniform, thereby improving the performance and consistency of the isolation film.

● Wettability: Ultrasonic spraying technology can evenly infiltrate the diaphragm material to the electrode surface to form a stronger isolation layer. This can effectively reduce the contact resistance and interface resistance between the diaphragm and the electrode, and improve the performance and cycle stability of the battery.

● Thickness control: By controlling the ultrasonic spraying process parameters, the thickness of the lithium battery diaphragm can be controlled. This is very important because the thickness of the diaphragm directly affects the charge-discharge performance and safety performance of the lithium-ion battery.

● High preparation efficiency: Ultrasonic spraying technology is easy to operate, the preparation process is fast, and can adapt to different sizes and shapes of batteries. Compared with other coating technologies, ultrasonic spraying can achieve uniform coating of large areas, improve production efficiency and process stability.

● Cost effective: Ultrasonic spraying technology does not require expensive equipment and complex processes, and the diaphragm material utilization rate is high. This can reduce production costs and improve the competitiveness of batteries.

YMUS ultrasonic spray lithium battery separator has the advantages of uniformity, wettability, controllable thickness, high preparation efficiency and high cost effectiveness. This technology can improve the performance and safety of the battery, and help improve the production efficiency and process stability of the battery.