google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Lithium battery diaphragm -- New energy and new material -- YMUS ultrasonic spraying

In recent years, the new energy automobile industry of our country is strongly supported by the state and governments at all levels, ushering in a period of rapid development. Affected by the transmission mechanism of the industrial chain, the relevant raw materials of the new energy automobile industry also usher in a new stage of development. As an important first-order material of power battery, the development of power battery diaphragm is accelerated under the guidance of national policies. With the rapid development of the power battery diaphragm industry, the diaphragm production technology is also improving. Coating technology as the key development direction of the power battery diaphragm industry in the future, in order to further improve the level of production technology, the state and governments at all levels have introduced various policies to support and promote the high-quality development of the industry.

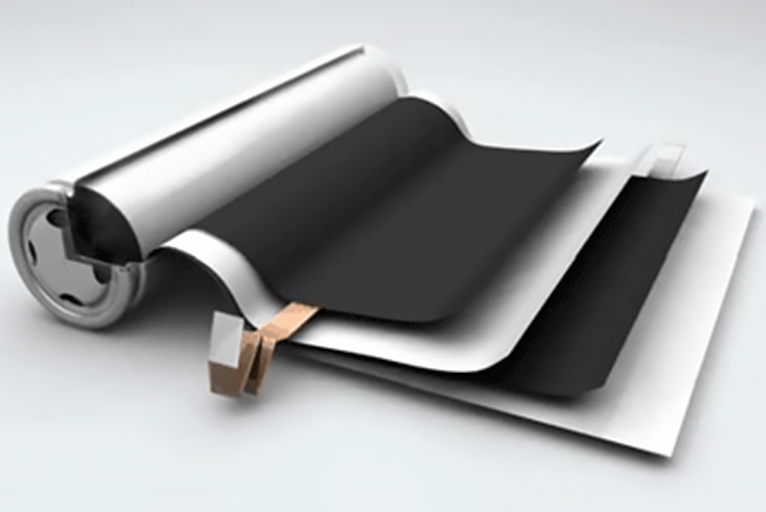

It is reported that lithium ion battery is the representative of modern high performance battery, composed of positive electrode, negative electrode, diaphragm and electrolyte four main parts. The diaphragm is a kind of thin film with microporous structure, which is the key inner component of the most technical barrier in the lithium-ion battery industry chain.

The basic properties of diaphragm should be:

1) Make positive and negative electrode materials avoid physical contact to prevent short circuit;

2) Easy to moisten, with good liquid retention ability;

3) with electrolyte ion permeability and low ion resistance;

4) Chemical and electrochemical stability;

5) Diaphragm as thin as possible;

6) Diaphragm to ensure that there is a certain strength, and has enough physical and mechanical durability;

7) The diaphragm does not contain particles and metals that can be dissolved by the electrolyte and substances harmful to the battery.

Requirements for diaphragm:

1) It has certain mechanical strength to ensure that the battery does not break under the condition of deformation;

2) Good ion transmission ability to reduce the internal resistance of the battery;

3) Excellent electronic insulation to ensure effective isolation between electrodes;

4) Have the ability to resist chemical and electrochemical corrosion, good stability in the electrolyte;

5) Strong ability to absorb electrolyte;

6) Low cost, suitable for large-scale industrial production;

7) Less impurity content, uniform performance.

YMUS-ZS400 Ultrasonic spraying equipment

Ultrasonic spraying plane substrate is glass, film battery, touch screen, fuel cell, nanomaterials and other production research and development of spraying equipment, with high spraying efficiency, low flow rate (controllable), uniform spraying layer, small atomized particles, online heating and other advantages. Compared with traditional spraying methods such as high pressure spraying, ultrasonic spraying equipment can control the speed and flow of spraying, and there will be no waste phenomenon such as sputtering in the spraying process. The solution utilization rate is more than 95%, reducing production costs and environmental pollution.