google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Photovoltaic panel colorless transparent toughness and good weather resistance coating - new energy - YMUS ultrasonic spraying

Polysilazane (PSZ) is a kind of inorganic polymer whose main chain is Si-N bond as repeating unit. Polysilazane can be divided into organic polysilazane (OPSZ) and aqueous polysilazane (PHPS) two major groups. Because of its special structure, polysilazane can be converted into SiCNO, SiCN or silica ceramics at high temperature, and the hardness after curing can reach more than 8H. Polysilazane has excellent corrosion resistance, oxidation resistance, radiation resistance, high temperature resistance, widely used in aerospace, semiconductor, photovoltaic cells, high temperature resistant coating, ceramic materials, resin materials and other fields. Silazane polymer can be converted into SiCN, SiCNO or silica ceramics at high temperature, so silazane polymer has important application value in high temperature resistant coating.

Polyazosilane is a new type of material, using polyazosilane as a precursor to prepare ceramic materials, has ultra-high temperature resistance, ultra-toughness, ultra-thin, ultra-corrosion resistance, ultra-high strength and other properties. In recent years, with the development of industrial technology, the demand for ceramic-based materials in the global market has been continuously released, thus driving the growth of the demand for polyazosilane. As a new material, polysilazane has broad application prospects in aerospace, semiconductor, high temperature resistant coating, ceramic materials and other fields. In the future, with the development of terminal industry, polysilazane market will maintain a rapid growth.

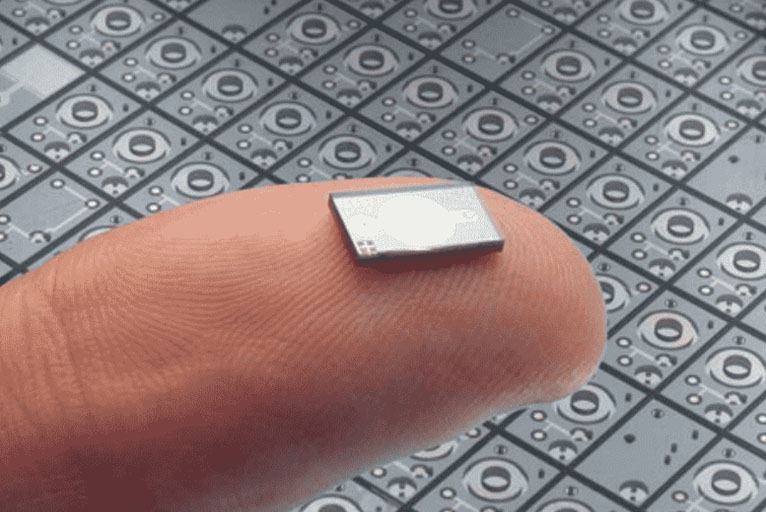

MEMS module

Related studies on silazane polymers

1) For preparing ceramic coatings

Many significant results have been obtained in the preparation of ceramic coatings with organic polysilazane. The pilot plant for coating the surface of carbon fiber can be carried out continuously from fiber surface treatment, spraying polysilazane solution, to coating curing and cracking, realizing the continuous processing of 10 000 m carbon fiber. In this process, the concentration of polysilazane is very important, too low (polysilazane mass fraction less than 2%) to achieve comprehensive protection of the fiber, too high (polysilazane mass fraction more than 10%) will cause the coating fragmentation. However, the concentration of polysilazane on ceramic and metal surfaces is required to be higher (mass fraction of polysilazane 20% ~ 60%) to cover up the defects on the substrate surface. By using ultrasonic spraying technology, nano coating and high uniformity film coating can be prepared at one time.

2) For preparing ceramic MEMS components

3) For preparing composite materials

Photovoltaic industry

Application of silazane polymer

Polysilazane is used for oxidation resistance of carbon materials

Carbon materials, such as graphite and carbon fiber, are indispensable in the field of high temperature resistance due to their characteristics of low density, high performance, no creep, ultra-high temperature resistance in non-oxidation environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion, and good corrosion resistance.

Due to the good temperature resistance of polysilazane, high temperature insulation can be achieved when the appropriate filler is added. Such as adding insulating glass beads in polysilazane, coating the surface of composite materials by spraying, after 200 ℃ curing, can play a good high-temperature protection effect on the composite materials.