google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Fuel cell membrane electrode preparation -- Film coating -- YMUS Ultrasonic spraying

At present, the industrialization of Proton Exchange Membrane Fuel Cell (PEMFC) still faces the problems of high cost and short life. The low utilization rate and high cost of catalyst layer platinum are important obstacles to the commercialization of fuel cell technology. Therefore, improving the utilization rate of platinum in catalytic layer is an important research direction in fuel cell research and development.

There are two main ways to reduce the platinum load of fuel cells and improve the performance of fuel cells:

(1) The activity and stability of the catalyst are improved by using the catalyst with high activity alloy and the catalyst support with high durability. This method can improve the performance of fuel cells to a certain extent, but there is still a lot of room for improvement. This is mainly because the "three-phase reaction interface" where the electrochemical reaction takes place is also a factor affecting the performance of fuel cells, which directly affects the transfer capacity of reactive gases, water and protons inside the fuel cells. Therefore, improving the fuel cell "three-phase reaction interface" is particularly important.

(2) By optimizing the preparation method of membrane electrode, improve the structure of membrane electrode and catalyst, and improve the performance of fuel cell. High quality membrane electrode preparation method is the basis of mass production of membrane electrode and the key to commercialization of fuel cell. Therefore, the preparation of membrane electrode has become one of the focuses of fuel cell research.

How to improve the preparation method of membrane electrode? How to improve the stability of membrane electrode?

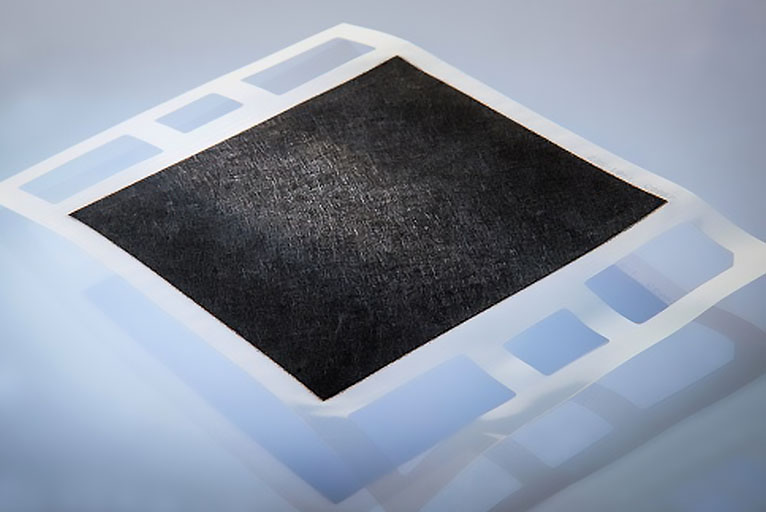

Ultrasonic spraying is a new preparation method for fuel cell membrane electrodes, which can accurately control the thickness of the catalytic layer and ensure the excellent uniformity of the catalytic layer. The preparation of film electrode by ultrasonic spraying method mainly includes the following two steps:

(1) Preparation of catalyst slurry by ultrasonic dispersion and other methods;

(2) Atomized spray the catalyst slurry onto the support body (gas diffusion layer or proton exchange membrane) under ultrasonic conditions;

The carbon microporous layer and catalytic layer were prepared by ultrasonic spraying technology, and the repeatability, utilization rate and uniformity of the spraying were verified. The average utilization rate of the slurry is higher than 85%, much higher than that of other spraying technologies.

Advantages of ultrasonic spraying method:

(1) By optimizing parameters such as the power and frequency of ultrasonic nozzle, the atomized catalyst slurry can have small rebound and is not easy to overspray, so as to improve the utilization rate of catalyst;

(2) The ultrasonic vibrator makes the catalyst particles highly dispersed, and the ultrasonic dispersing syringe has the effect of secondary stirring on the catalyst slurry, which greatly reduces the chemical contamination of platinum and the probability of reducing the reactive area;

(3) Simple operation, high degree of automation, suitable for mass production of membrane electrode.