google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

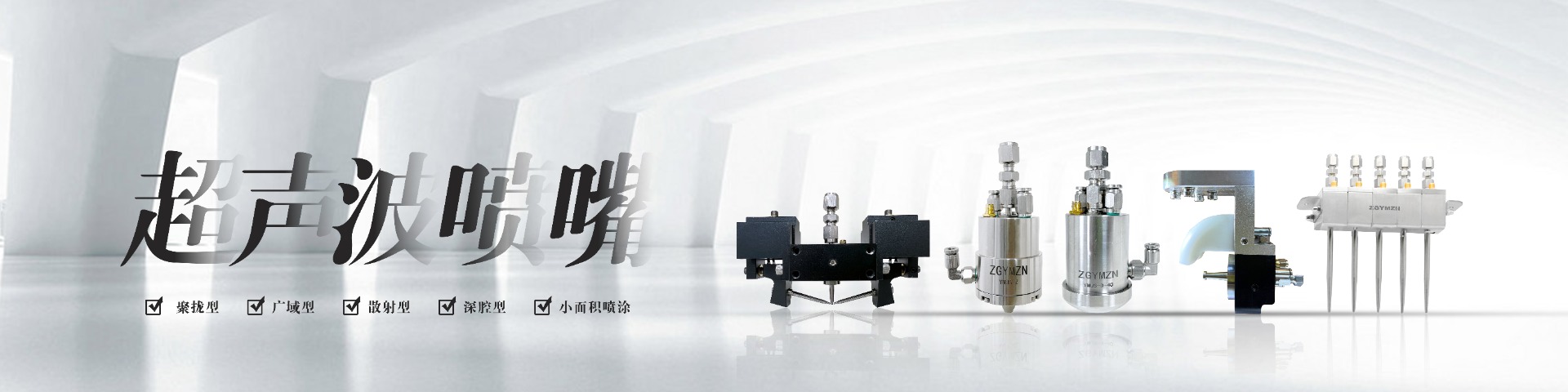

Ultrasonic spraying technology realizes the application of anti-glare and high transmittance coating on glass surface

Technical principle

Atomization process: The high-frequency vibration of ultrasound is used to break the solution containing specific functional materials into tiny droplets. The particle size of these droplets is uniform and small, usually in the micrometer or even nanometer range, laying the foundation for the subsequent formation of a uniform and high-quality coating on the glass surface.

Spray deposition: The atomized droplets are evenly delivered to the glass surface through a precisely controlled airflow. In this process, the effect of ultrasound enables the droplets to be deposited in a more stable and uniform manner, reducing the thickness deviation and defects of the coating.

Functional materials

Anti-glare ingredients: Generally, nanoparticles with special optical properties are used, such as nano-silicon dioxide, nano-titanium oxide, etc. These nanoparticles form a layer of microscopically uneven but highly uniform structure on the surface of the glass. When light hits the surface of the coating, multiple scattering occurs, which effectively reduces the intensity of the reflected light and achieves the anti-glare effect.

High-transmittance materials: Select materials with high transmittance to visible light, such as special organic polymers or inorganic-organic hybrid materials, to ensure that while achieving the anti-glare function, it will not have a negative impact on the light transmission performance of the glass. These materials can work synergistically with the anti-glare ingredients, so that the glass can maintain a high visible light transmittance while reducing reflected light, ensuring clear vision.

Application advantages

Excellent optical performance: effectively reduce the reflectivity of the glass surface, reduce the interference of ambient light, and improve visual comfort. Under various lighting conditions, it can provide users with a clear, glare-free visual experience, while ensuring high transmittance and restoring true colors to the greatest extent.

Uniform coating quality: Ultrasonic spraying technology can achieve a high degree of uniformity in the coating, avoiding problems such as flow marks and uneven thickness that may occur in traditional coating methods. This not only improves the aesthetics of the glass, but also ensures that the optical properties of the glass are consistent in different parts.

Wide applicability: Suitable for a variety of types of glass, including flat glass, curved glass, tempered glass, etc., can be used in building curtain walls, car windshields, electronic equipment displays and other fields.