google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

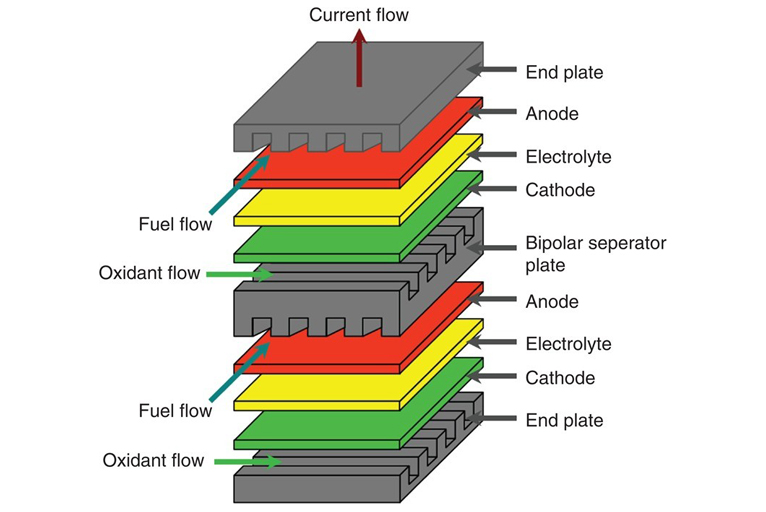

Solid Oxide Fuel Cell (SOFC) is an all-solid energy conversion device, which can directly convert chemical energy in fuels (such as hydrogen and carbon monoxide) into electric energy, and the conversion efficiency is relatively high. Solid oxide fuel cell (SOFC) is a new energy system, which is called the third generation fuel cell. It uses ceramic electrolyte and has unique advantages such as wide fuel application range, high waste heat utilization and low cost.

As a core component, electrolyte is mainly used to conduct ions and form a conductive path between cathode and anode. Solid oxide fuel cells have higher requirements for electrolytes, and SOFC usually operates at higher temperature (700-1000℃). High temperature operation has some advantages, for example, in this temperature range, the kinetic speed of electrode reaction is accelerated, which reduces the polarization loss of the battery, thus improving the power generation efficiency of the battery. At the same time, high temperature is also beneficial to fuel reforming. For example, some hydrocarbon fuels (such as natural gas) can be converted into more oxidizable fuels such as hydrogen and carbon monoxide by internal reforming near the anode or before entering the anode, which can broaden the fuel selection range.

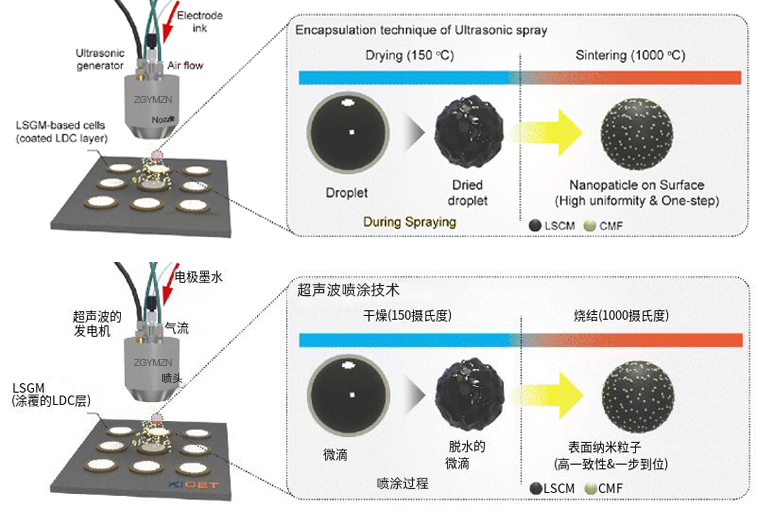

Ultrasonic spraying of solid electrolyte LSGM material. LSGM is an important solid electrolyte material, and its performance directly affects the performance and efficiency of SOFC. By optimizing the preparation process and doping elements of LSGM, its ionic conductivity and chemical stability can be further improved, thus improving the performance of SOFC.

Ultrasonic spraying can ensure the high uniformity of the coating, usually more than 95%, and can accurately control the thickness of the coating from nano to micron. This is very important for the coating of LSGM electrolyte material. Uniform coating can ensure the stability of electrolyte in the battery and reduce the problems such as too large or too small local current density, thus improving the performance and efficiency of solid oxide fuel cells. Compared with some traditional methods of preparing LSGM coating by high-temperature sintering, ultrasonic spraying technology can be carried out at a relatively low temperature, which avoids the possible influence of high temperature on the properties of LSGM materials, and also reduces the energy consumption in the preparation process and the requirements for high temperature resistance of equipment.

Shanghai Yangmi has produced large-area ultrasonic spraying equipment to ensure the consistency of coating quality in mass production. It is necessary to accurately debug and control the ultrasonic spraying equipment and establish strict production technology and quality control standards to ensure that each coating can meet the expected performance and quality requirements.