google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Medical non-woven fabric -- medical consumables -- YMUS ultrasonic spraying

In recent years, the demand for non-woven fabric is growing very fast. As a new medical material, medical non-woven fabric has a very broad application prospect and will create more value in the medical field in the future.

Medical non-woven fabric will pay more attention to environmental protection and sustainability. For the production of medical non-woven fabrics, by improving the development of cocoon and silk companies, green technology, ecological materials and other ways, the produced medical non-woven fabrics are more environmentally friendly and sustainable, and will better meet people's health needs. Medical non-woven fabrics can not only be used as traditional dressings and bandages, but also have more functions. Medical non-woven fabrics with enhanced hydrophobic function and stronger antibacterial properties can be made to meet different needs.

Ultrasonic spraying technology in the preparation of medical non-woven fabric can be through ultrasonic atomization, the liquid material to micron or even submicron particles spray on the non-woven material, so as to prepare higher quality, better performance of medical non-woven fabric.

1. Improve the appearance and performance of materials. Ultrasonic spraying technology makes the surface of medical non-woven fabric flat, weak corrosion, strong permeability, thereby improving the physical and chemical properties of medical non-woven fabric, so that it is more suitable for the application in the medical field.

2, high precision, good uniformity. Ultrasonic spraying technology can use constant spray amount and uniform spray distribution, can prepare more uniform product surface of medical non-woven fabric.

3. Fast and efficient. Ultrasonic spraying technology is fast, high efficiency, can reduce the preparation time to a minimum, so as to improve production efficiency and production capacity to meet the market demand.

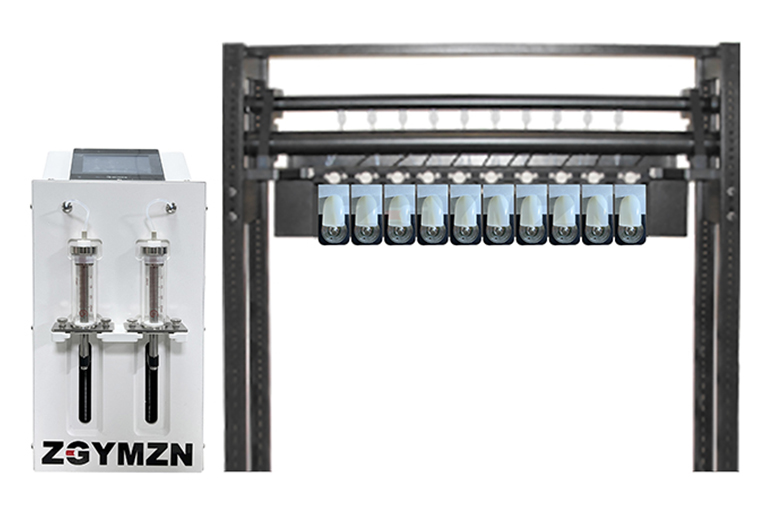

On-line spraying system, a mass-produced automatic ultrasonic spraying equipment, can be equipped with scattered ultrasonic nozzle, and can be equipped with multiple nozzle parallel work. The on-line spraying system is also equipped with a unique precision constant current metering pump system, which can achieve 24 hours of continuous steady fluid supply. Optional configuration of carrier gas control, base heating, vacuum adsorption, exhaust system and other auxiliary devices, especially suitable for mass production and large area film production and preparation.