google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of nano-sized film coatings by ultrasonic atomization -- Ultrasonic atomization -- YMUS ultrasonic spraying

Ultrasonic atomizing equipment is simple, can continuously and quickly prepare nano particles, and can control atomizing particle size, morphology, crystallinity and other properties of ultra-high precision. Therefore, ultrasonic atomization has become the first choice for the preparation of ultrafine particles.

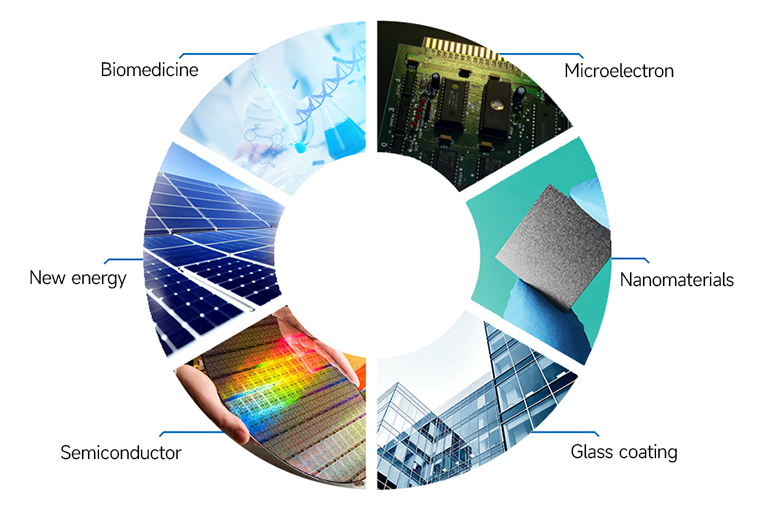

An uncommon nanoscale coating preparation technology becomes "the first choice of nanoscale preparation", which is a problem to be studied. As we all know, nano coating has a series of good properties such as electrical, optical, catalytic, gas sensitive, so it has a wide range of applications in optical materials, catalysts, medicine, electronics, semiconductor, aerospace and other fields.

The unique characteristics of nanometer coating depend on its particle size, morphology, surface composition and other characteristics. It is very important to control the morphology and particle size of atomized particles. In the production of nanoscale coating methods such as sol-gel, hydrothermal method, solid phase method, they more or less have some problems have not been solved, such as the size of the grain and crystal morphology is not easy to control, size distribution, high production costs. In order to solve these problems, ultrasonic technology is introduced into material synthesis, among which ultrasonic atomization technology has been gradually applied in the field of nano coating research. So far, ultrasonic atomization has been widely used in medical ultrasonic atomization, surface coating and other fields.

In the laboratory, YMUS ultrasonic atomization based material preparation technology has been used to prepare various components and forms of materials, including powder, film, coating, fiber and nanocomposite materials. Nano coatings prepared by ultrasonic atomization not only have the advantages of fluid atomization, but also have better properties because the reaction system is activated by ultrasonic.

Ultrasonic atomizing spraying mechanism:

The ultrasonic nozzle uses the piezoelectric effect to convert electrical energy into high-frequency mechanical energy, which is transferred to the liquid to generate standing waves. The liquid is introduced into the atomizing surface through the sprinkler head. When the liquid leaves the atomizing surface of the sprinkler head, it is broken into uniform micron level fine mist droplets, so as to achieve atomization. In the process of ultrasonic spraying, the size and distribution of droplets can be precisely controlled, so that very small droplets and particles can be quickly evaporated, resulting in particles with high specific surface area, forming a thin film coating.

Note:Application field of ultrasonic spraying

Comparison of atomizing technology:

★ The kinetic energy atomization of gas and liquid is used;

★ Spray impact force is large, will cause spatter and waste of raw materials;

★ the uniformity of atomized particles is poor;

★ Easy to block the nozzle;

★ Can not accurately control the spray flow, can not be low flow continuous spray;