google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation and application of carbon nanotube thin films -- nano-material -- YMUS Ultrasonic spraying

Photodetectors are widely used in remote sensing, night vision, reconnaissance, medical imaging, environmental protection, chemical detection and other fields. The structure and performance of photoelectric detection materials directly affect the performance of photodetectors. Recently, carbon nanotubes (CNTS) have become an indispensable material for photoelectric detection due to their unique optical and electrical properties. In the past research mainly focused on the photoelectric response mechanism based on single carbon nanotubes, but the future application scenario is bound to be based on carbon nanotubes thin films. Therefore, how to prepare large area, high density, high orientation and high uniformity carbon nanotube film, and on this basis to prepare photodetectors has become the photoelectric application field of carbon nanotube YMUS experiment test.

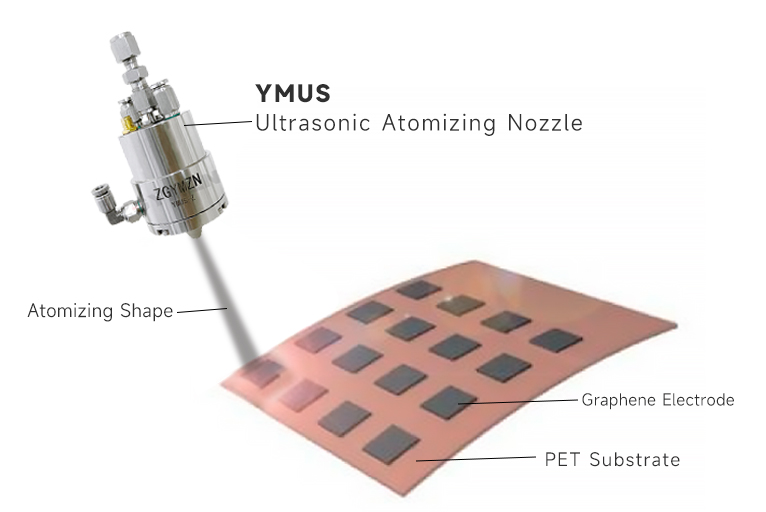

Note:Graphene electrode

Nanomaterials and low-dimensional materials have unique structures and photoelectric properties, which make great progress in the properties of the tunability, adaptability and reconfiguration of nanomaterials. Among them, carbon material is the only semiconductor material including zero-dimensional fullerene, one-dimensional carbon nanotubes, two-dimensional graphene and three-dimensional graphite. These low-dimensional carbon nanomaterials have the advantages of smaller size and larger specific surface area, and they are excellent in electrical, optical, optoelectronics and flexible electronics.

YMUS ultrasonic spraying technology has the advantages of high film forming efficiency, can improve the uniformity of film coating, suitable for the preparation of large area film, and by controlling the concentration of solution, spraying flow and velocity of the film thickness can achieve good regulation. It was found that the solution of single-walled carbon nanotubes was dispersed by the mixed solution of n-propanol aqueous solution and perfluorinated sulfonated resin, and the dispersion solution was sprayed on polyethylene terephthalate (PET) substrate. The conductivity of carbon nanotube films was improved by P-type doping.

Note:Schematic diagram of ultrasonic atomizing spraying

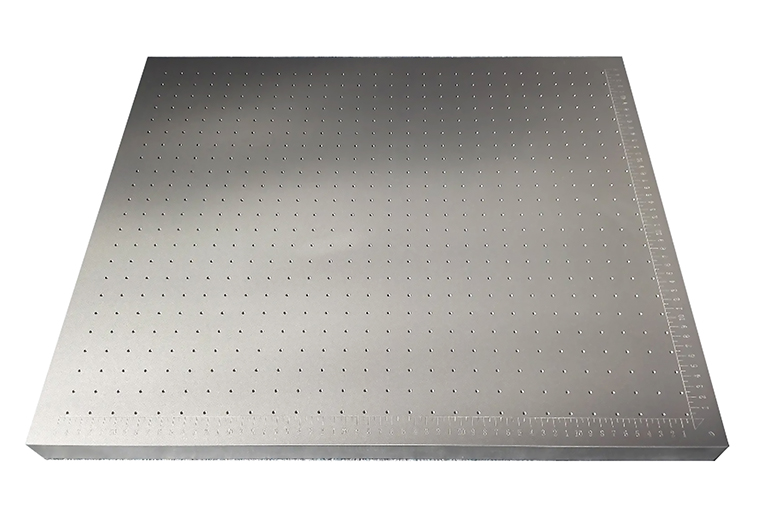

YMUS is a small batch production of automatic ultrasonic spraying equipment, which can be equipped with various types of ultrasonic nozzles and can be equipped with multiple nozzles to work in parallel at the same time. YMUS-ZS400 ultrasonic spraying system can also be equipped with a unique precision constant current liquid supply system, which can achieve 24 hours of uninterrupted constant liquid supply. Optional configuration of carrier gas control, base heating, vacuum adsorption, exhaust system and other auxiliary devices, especially suitable for small mass production grade and more than 400*400mm film production and preparation.

YMUS-ZS400 Ultrasonic spraying system Vacuum adsorption heating platform