google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spray biodegradable material/PLA -- Medical field -- YMUS Ultrasonic spray

Polylactic Acid (PLA) is a biodegradable polymer material that is widely used in the medical field. The following describes the application of PLA in the medical field and the advantages and advantages of PLA prepared by ultrasonic spraying.

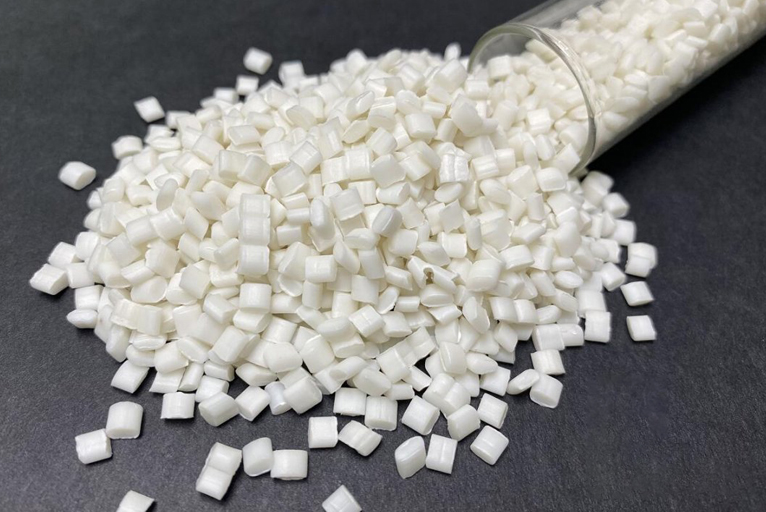

PLA material

Ⅰ. Application of PLA in the medical field:

· Medical sutures: PLA has good biocompatibility and degradability and can be used to manufacture sutures for surgical procedures and wound repair.

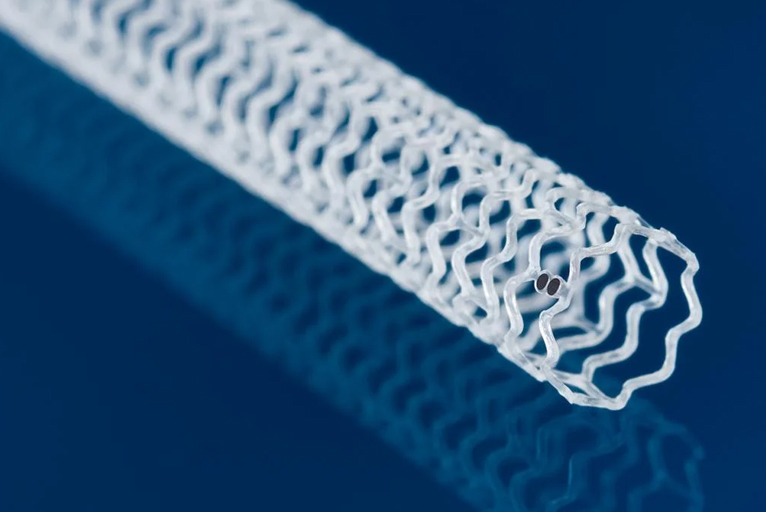

· Medical devices: PLA can prepare various medical devices, such as bone nails, screws and supports. These devices have good biocompatibility and will be gradually absorbed and degraded by the human body after a certain time.

· Injection use: Because PLA is plastic and injectable, drug carriers such as slow-release microspheres and nanoparticles can be prepared for drug delivery.

3D printing: PLA materials are widely used in 3D printing, which can be used to manufacture bionic tissues, prostheses and bone scaffoldings.

Biodegradable scaffold

Ⅱ. The advantages and advantages of ultrasonic spraying PLA:

· High precision and uniformity: Ultrasonic spraying technology uses the vibration force of ultrasonic waves to evenly spray PLA solution on the substrate in the form of fine particles, so as to achieve a high precision and uniform coating.

· Reduced crystallization: During the ultrasonic spraying process, the particles dry rapidly on the substrate, reducing the chance of PLA crystallization and avoiding the formation of uneven structures.

· Maintain the physical properties of PLA: Due to the rapid solvent volatilization during ultrasonic spraying, PLA particles can be cured quickly, maintaining their original physical properties.

· Thickness and cost can be controlled: Ultrasonic spraying technology can adjust spraying parameters and concentration according to needs, so as to achieve thickness control of PLA film, and at the same time, it has low preparation cost.

· Suitable for complex shapes and porous materials: Ultrasonic spraying is suitable for substrates of various shapes and can produce uniform coatings on porous materials for complex medical device and tissue engineering applications.

PLA is widely used in the medical field. YMUS ultrasonic spray technology, as a method for preparing PLA materials, has the advantages of high precision, good uniformity, maintaining physical properties, controlling thickness and low cost, and is expected to play an important role in medical engineering.