google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Fuel cell membrane electrode ultrasonic spraying preparation process -- Hydrogen energy storage -- YMUS ultrasonic spraying

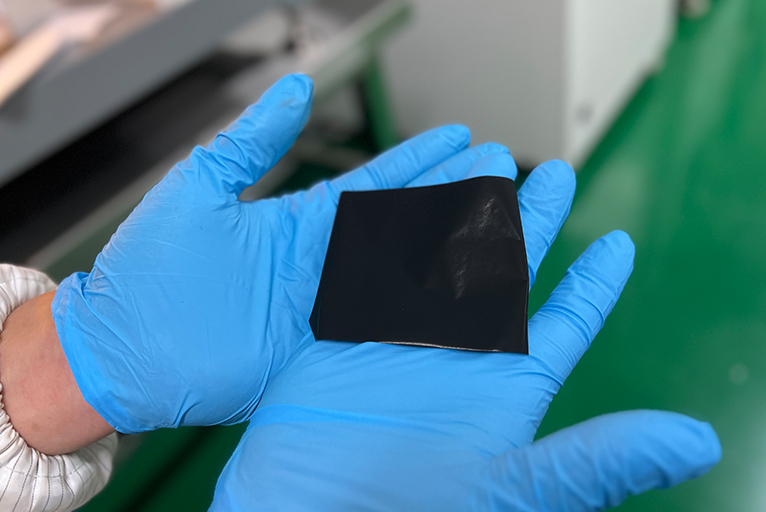

The YMUS ultrasonic spraying process for preparing fuel cell membrane electrodes has the advantages of fast, uniform, precise thickness control and low cost. At the same time, ultrasonic spraying reduces the possibility of particle agglomeration, improves the uniformity and stability of the electrode, and helps to improve the performance and efficiency of the fuel cell.

A uniform catalyst coating is deposited on PEM fuel cells, GDL, electrodes, various electrolyte membranes and solid oxide fuel cells, sprayed with a suspension containing carbon black ink, PTFE binder, ceramic paste, platinum and other precious metals. Ultrasonic coatings of other metal alloys, including platinum, nickel, iridium and ruthenium fuel cell catalysts in metal oxide suspensions, can also be used to manufacture PEM fuel cells, polymer electrolyte film (PEM) electrolyzers, DMFC (direct methanol fuel cells) and SOFC (solid oxide fuel cells) for large loads and high cell efficiency.

The evenly dispersed solution is injected into the syringe of the ultrasonic spraying equipment. The ultrasonic vibration aggregates the particles in the suspension into uniform mist particles and prepares them on the electrode support material. The spraying speed and spraying distance need to be determined according to the specific material and equipment parameters. After spraying, the electrode sample is dried, and the catalyst and conductive agent in the electrode are fixed by on-line heating, and the polymer film is well bonded. The prepared membrane electrodes need to be tested and evaluated in terms of electrochemical performance, catalytic activity and stability. These tests can help optimize the preparation process and improve electrode performance.

Application

◆ New energy: fuel cells, membrane electrodes, thin film solar cells, proton exchange membranes, lithium battery membranes, perovskite solar cells, solar photovoltaic wafers, etc.

◆ Medical: balloon catheter, blood vessel syringe, stent, biosensor, microfluidic chip, heart valve, antibacterial coating, etc.

◆ Microelectronics semiconductor: silicon carbide seed adhesion, flux, photoresist coating, conductive coating, hydrophilic coating, conductive ink, PI, PET, etc.

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresistance film, transparent conductive, electrochromic, etc.

◆ Nanotechnology: carbon nanotubes, polymer fibers, nanofilms, carbon nanotube films, MXenes, graphene composites, etc.